- Leadership Development

- Operational Excellence

- Industry 4.0 – Management Digitalization

- Food & Bev

- Construction

- Manufacturing

- Heavy Industry

- The Manager's Journey

- Cross-platform tool

- Digital Gemba Walk

- Collaboration and Rituals

- Coaching and Improvement

- Knowledge Center - New

- All Features

- Industry 4.0 and 5.0

Case Studies

- Continuous Improvement

- Frontline Managers

- Key Behaviroral Indicators

- Management Skills

- Productivity

- Free Resources

TABLE OF CONTENT

Share this article, download a pdf version., subscribe to our newsletter, toyota kata guide: improvement kata & coaching kata.

Downloaded on: July 5, 2024

• April 24, 2023

dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190584" data-dropdown-placement-param="top" data-term-id="257190584">Lean is a management and organization method that aims to identify and eliminate sources of waste in the work process, allowing the company to increase its performance. In order to make this method a long-term success, the change needs to be made at the human level . Managers and their teams must change the way they think, act and solve problems. That is where the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata comes in, a method that advocates knowledge transmission and repetition over the long term to promote dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">continuous improvement .

With the help of our expert Yves LeBrasseur, we invite you to delve into the subject of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata , to understand how it works, its key elements and its benefits for the company.

Key takeaways

- Understanding the Toyota Kata is crucial for successfully implementing continuous improvement practices in any organization.

- The Toyota Kata provides a structured approach to problem-solving and developing a culture of continuous learning and improvement.

- By following the Toyota Kata, organizations can foster a mindset of experimentation, iteration, and adaptability.

- The Toyota Kata emphasizes the importance of setting clear goals, defining a target condition, and engaging in deliberate practice to achieve desired outcomes.

- Implementing the Toyota Kata requires consistent coaching and leadership support to empower employees and drive sustainable improvement efforts.

In a hurry? Save this article as a PDF.

Tired of scrolling? Download a PDF version for easier offline reading and sharing with coworkers.

Why talk about dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata ?

"One story has often come up in my career: that of a boss who, after hearing about the benefits of Kaizen , the success of Toyota and many other companies that have used this management method, decided to apply it in his own company. To do so, he hires a consultant who comes to do a training with improvement activities and sets up pilot projects with employees. At first, everything went well and everyone was delighted with the new processes. Then the consultant leaves, and unfortunately the initiative slowly disappears. A very classic scenario in the field of Lean Yves LeBrasseur, Senior Expert at Proaction International

What is dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata ?

In dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190586" data-dropdown-placement-param="top" data-term-id="257190586">Japanese dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190595" data-dropdown-placement-param="top" data-term-id="257190595">martial arts , the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190608" data-dropdown-placement-param="top" data-term-id="257190608">Japanese dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190608" data-dropdown-placement-param="top" data-term-id="257190608"> word "kata" ("form") designates a series of codified and coordinated movements performed as part of a training exercise, which, through repetition, become reflexes, dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190601" data-dropdown-placement-param="top" data-term-id="257190601">second nature . These exercises, when practiced continuously, become perfectly mastered routines and lead to an improvement in technique.

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata comes from a dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190616" data-dropdown-placement-param="top" data-term-id="257190616">management book written by American researcher dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190582" data-dropdown-placement-param="top" data-term-id="257190582">Mike Rother " dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190598" data-dropdown-placement-param="top" data-term-id="257190598">Toyota Kata dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190598" data-dropdown-placement-param="top" data-term-id="257190598">: Managing People for Improvement , dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190593" data-dropdown-placement-param="top" data-term-id="257190593">Adaptiveness , and dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190600" data-dropdown-placement-param="top" data-term-id="257190600">Superior Results " (McGraw-Hill Education Edition). In it, the author draws on the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodology of the Toyota dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">Continuous Improvement Model and explains how the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190586" data-dropdown-placement-param="top" data-term-id="257190586">Japanese car manufacturer Toyota manages both dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">continuous improvement and employee know-how, using dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">improvement katas and dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190583" data-dropdown-placement-param="top" data-term-id="257190583">coaching katas . Indeed, in studying Toyota's way of doing things, dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190582" data-dropdown-placement-param="top" data-term-id="257190582">Mike Rother found that the organization's managers could naturally install a method of thinking and acting within their team that aimed to achieve the desired objectives and solve problems.

It is to this same practical method that he gave the name dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata . In his book, he develops its findings and helps to understand why some companies do not manage to use the full potential of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190584" data-dropdown-placement-param="top" data-term-id="257190584">Lean and make only minor progress while other companies (like Toyota) manage to achieve much higher levels of performance by integrating improvement and dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190593" data-dropdown-placement-param="top" data-term-id="257190593">adaptation into the daily lives of their employees. It also demonstrates that the model proposed by Toyota applies to all processes and all types of companies.

To summarize, the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata is a method of creating a culture of learning, knowledge transfer, and dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">continuous improvement in the company by implementing these famous routines at different levels.

According to dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190582" data-dropdown-placement-param="top" data-term-id="257190582">Mike Rother , this management model includes two distinct routines:

- The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">Improvement Kata - Routine and Implementation

- The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190583" data-dropdown-placement-param="top" data-term-id="257190583">Coaching Kata - Coaching

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata includes at least three interlocutors: a learner (coachee), a coach, and a second coach.

Our expert's point of view on the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata

After studying the Toyota dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodology for a long time, dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190582" data-dropdown-placement-param="top" data-term-id="257190582">Mike Rother realized that kaizens exist, but their functioning depends mainly on the corporate culture. Indeed, the company must be ready to put the processes in place, and making dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">kaizens must become a reflex for the organization. Thus, for these reflexes to be made and in the right way, three elements are necessary:

Knowledge of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">Kaizen method

To carry out an improvement project, it is necessary to precisely define the team and the objective, to proceed step by step, and to have a structured analysis dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodology . The latter can be quite simple, but it must have a well-defined framework and allow trial and error.

Employee training

Training and especially coaching of teams are essential. dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190582" data-dropdown-placement-param="top" data-term-id="257190582">Mike Rother 's studies have shown that field coaching is significant at Toyota with much repetition. To be successful in an activity, dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190592" data-dropdown-placement-param="top" data-term-id="257190592">practice routines, and dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190626" data-dropdown-placement-param="top" data-term-id="257190626">coaching cycles are key factors. So, to be good at dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">kaizens , you have to do them often, a lot, and get expert coaching to make sure that everything goes well. The organization will therefore need people who know and master the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodology to guide the employees in a constructive way.

Management support

When we want to implement dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">Kaizen dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodologies , we are making a change in a company. This is called change management . One of the main points for the organization is to start by defining why it wants to embark on a dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata approach and its goal. Then, they need to have a clear vision of where they want to go and how far they want the method deployed. So that requires particularly strong support from management.

"In companies that have been very successful with dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata , it was often the higher-ups who would go out and coach in the field to show the importance of the process, but also to get directly involved, because that's how you get a culture of improvement in place."

How to implement the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata model

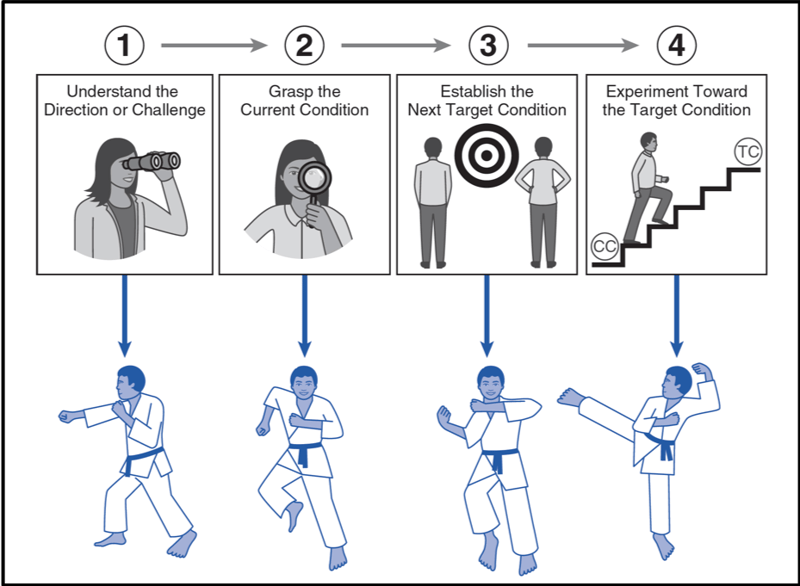

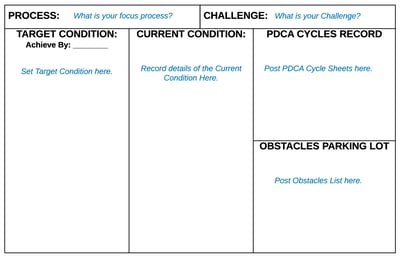

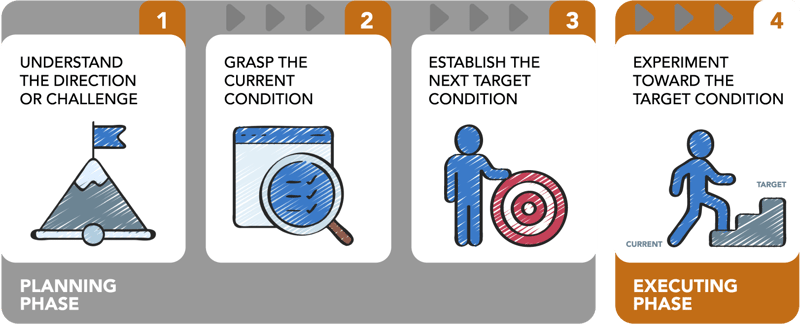

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">improvement kata consists of 4 key steps.

The purpose of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">Improvement Kata is to create and anchor continuous dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190605" data-dropdown-placement-param="top" data-term-id="257190605">process improvement ( dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">Kaizen ) habits within the teams, to learn more about how the company works, and to use this better understanding to optimize the way of working by trying new routines. It, therefore, focuses on learning and exploring new ways of doing things.

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">improvement kata consists of 4 major steps.

.webp?width=600&height=651&name=PAI_Blogue_ToyotaKata_4etapes_EN%20(1).webp)

Planning phase

1. Define the company's direction - Target Condition

You need to understand the organizational goal, the vision of the company (link to visionary leader article), the direction it wants to take, or the challenge to be met. Identifying this end goal will allow you to stay focused on it and not lose focus, but also to motivate employees towards this goal.

2. Understand the Current Situation - Actual Condition

You need to examine and understand in depth the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190621" data-dropdown-placement-param="top" data-term-id="257190621">current state - i.e., how the company operates, what you know, but also what you don't know and could learn. You must list processes, workflows, and results using the relevant indicators to succeed. Then you need to analyze them and objectively understand how they work.

3. Determine the next target condition

Here you have to define the next goal to be reached or the challenge to overcome to get closer to the goal (company vision). Ask yourself what could be changed or improved to get to this dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190591" data-dropdown-placement-param="top" data-term-id="257190591">next target condition , and then set a specific time frame for implementing that change. Focus on the process more than the outcome because a good process will lead to good results.

Experimentation Phase

4. Experimenting to overcome obstacles

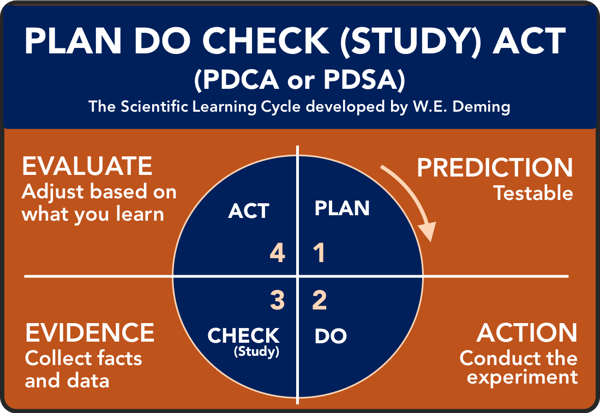

For this dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190602" data-dropdown-placement-param="top" data-term-id="257190602">last step , you must conduct various experiments to overcome the identified barriers and learn from the results to see what works and what does not. To do this, use the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190597" data-dropdown-placement-param="top" data-term-id="257190597">PDCA cycles ( dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190606" data-dropdown-placement-param="top" data-term-id="257190606">Plan-Do-Check-Act ) by applying the following dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190623" data-dropdown-placement-param="top" data-term-id="257190623">small steps :

- Plan - Define project objectives, participants, timeline, barriers

- Do - Implement the project on a small scale, on a reduced dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190610" data-dropdown-placement-param="top" data-term-id="257190610">cycle time

- Check - Check the results to see what went well and what needs to be improved

- Act - Work on improving the identified problems

This method will allow you to test the improvement measures on a small scale and remove the obstacles individually to better understand and adapt the work processes.

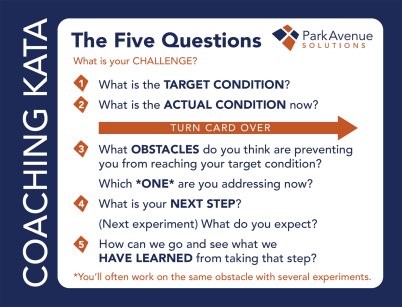

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190628" data-dropdown-placement-param="top" data-term-id="257190628">coaching kata dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190628" data-dropdown-placement-param="top" data-term-id="257190628"> cards in 5 questions

Kata coaching supports and complements the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">improvement kata . Its goal is to ensure that company leaders and managers can accompany and guide their employees in the kata improvement process, transforming them into coaches themselves.

To help the learner overcome the challenges that arise and adopt a particular state of mind while acquiring the necessary confidence, the coach asks 5 dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190614" data-dropdown-placement-param="top" data-term-id="257190614">kata questions that respond to the different stages of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190581" data-dropdown-placement-param="top" data-term-id="257190581">improvement kata :

- What is the target condition?

- What is the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190587" data-dropdown-placement-param="top" data-term-id="257190587">current condition ?

- What obstacles are preventing you from achieving the target condition?

- What is the next step? What do you think will happen?

- When can we see what we have learned by taking this step?

Four other questions arise to better answer this last question:

- What do you have planned as your final step?

- What did you expect?

- What actually happened?

- What did you learn?

This series of questions is essential to dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190583" data-dropdown-placement-param="top" data-term-id="257190583">coaching Kata; they depend on each other. It is, therefore, necessary to answer them in order, with as much precision as possible (answer the first one well to better answer the second one and so on). They can be applied in all contexts and at all levels of the hierarchy.

Why is coaching so crucial in applying the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata principle?

Coaching is a fundamental element of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata . For example, practice is essential if I want to improve in a sport. I will have to train as much as possible, ideally on dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190618" data-dropdown-placement-param="top" data-term-id="257190618">daily practice , so that the techniques and movements of the sport in question become automatic. But I must also be guided and accompanied to do things correctly and efficiently. This is where the coach will fully play his role.

In the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata , he will allow having the right dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190612" data-dropdown-placement-param="top" data-term-id="257190612">methodology and the right tools. He will help to choose the right projects, not go too far into the details, and always keep the right structure. He will ensure a real follow-up because good coaching always includes a before (preparation of the coaching sessions), a during (coaching as such), and an after (possible points of improvement).

The Toyota Kata will be a key component here by having a coach who will closely follow the person who wants to learn the right methodology. And that's our expertise at Proaction International; it's part of our DNA: coaching managers and helping them improve in the workplace. This requires people to have the necessary training, skills, background, and experience. And let's not forget the tools that facilitate dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">continuous improvement and follow-up. That includes UTrakk , an online dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190619" data-dropdown-placement-param="top" data-term-id="257190619">management system platform that allows us to track our coaching rigorously.

The benefits of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata for the company

The application of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata model has many benefits for the company. Here are some of them:

- Establish a solid communication base between the manager and his team on the objectives to be reached and the challenges to be overcome;

- Dealing with change in a more organized and efficient manner;

- Fostering transparent communication (transparency link in business) and collaboration;

- Encourage autonomy and initiative;

- Encourage learning and the use of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190588" data-dropdown-placement-param="top" data-term-id="257190588">scientific thinking ;

- Identify areas for improvement;

- Develop innovative and creative solutions to challenges;

- Improve employee motivation, commitment , and satisfaction;

- Reduce waste and unnecessary processes by applying sustainable solutions;

- Increase productivity and, consequently company's performance in the long term.

The dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata method is a great asset for installing sustainable thinking and behavioral routines within the company to achieve the desired objectives and develop the necessary dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190589" data-dropdown-placement-param="top" data-term-id="257190589">problem-solving skills. It emphasizes the importance of learning and practicing to keep improving in a constantly changing environment.

The application of Katas allows for the reinforcement of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190584" data-dropdown-placement-param="top" data-term-id="257190584">Lean management techniques and can even be associated with other Lean tools such as the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190596" data-dropdown-placement-param="top" data-term-id="257190596">Kanban method , dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190613" data-dropdown-placement-param="top" data-term-id="257190613">Value Stream Mapping , 5S , dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190611" data-dropdown-placement-param="top" data-term-id="257190611">Six Sigma , dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190590" data-dropdown-placement-param="top" data-term-id="257190590">Kaizen , dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190599" data-dropdown-placement-param="top" data-term-id="257190599"> Gemba Walk checklist , etc... to allow the organization to maintain its competitive advantage by being ever more efficient and innovative

FAQ - Toyota Kata

What is toyota kata.

The Toyota Kata methodology is a scientific way of developing a culture of continuous improvement. Developed by Toyota, it is a structured approach to help organizations to adapt, create, and innovate in the face of unpredictable situations.

Who developed the Toyota Kata methodology?

The Toyota Kata methodology was developed by Mike Rother, an American researcher, and writer in his book, "Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results".

Why is Toyota Kata important for organizations?

Organizations that implement the Toyota Kata methodology witness measurable improvements in productivity, quality, safety, and employee satisfaction. It helps organizations to develop a continuous problem-solving culture, where everyone in the organization can work towards improving processes and productivity, leading to long-term success.

What are the key components of the Toyota Kata process?

The Toyota Kata process has two key components:

The Improvement Kata - This component is designed to address problems and make improvements by constantly testing, adjusting, and improving processes. It promotes a culture of continuous improvement and experimentation.

The Coaching Kata - This component is designed to train managers and team leaders in problem-solving skills, leadership, and coaching techniques. It helps managers and team leaders to develop the skills and tools for guiding their teams towards improvement continuously.

How can organizations implement Toyota Kata in their daily operations and improve their productivity?

Organizations can implement Toyota Kata in their daily operations by following a few key steps:

- Start by identifying the organization's current condition and set a vision for the future.

- Create a roadmap to achieve the desired future state.

- Start with small and simple experiments to test the changes in processes.

- Drive continuous learning and improvement by sharing insights and feedback.

By following these steps, organizations can implement Toyota Kata and create a culture of continuous improvement, leading to increased productivity and long-term success.

Do you want to implement the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata in your organization ?

With over 15 years of experience in the coaching field, our experts are here to accompany you and help you implement and use the power of the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata to increase your company's dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190607" data-dropdown-placement-param="top" data-term-id="257190607">metrics in the long term.

Adeline de Oliveira

Writer and editorial manager for about 15 years, Adeline de Oliveira is passionate about human behavior and communication dynamics. At Proaction International, she covers topics ranging from Industry 5.0 to operational excellence, with a focus on leadership development. This expertise enables her to offer insights and advice on employee engagement and continuous improvement of managerial skills.

Déli-Porc Develops an Agile, Digitalized Culture Focused on Optimization

Kefor maximizes its performance by optimizing manager skills, le goupe maurice: motivate and retain talents by focusing on the leadership development of managers.

© 2023 Proaction International Inc. All rights reserved. Terms of Use | Privacy Notice | Cookie Notice

- Product overview

- Improvements

- Learning Center

- Microsoft Teams

- Integrations

- Enterprises

- Manufacturing & Production

- Building & Construction

- Engineering

- State and Government

- Other businesses

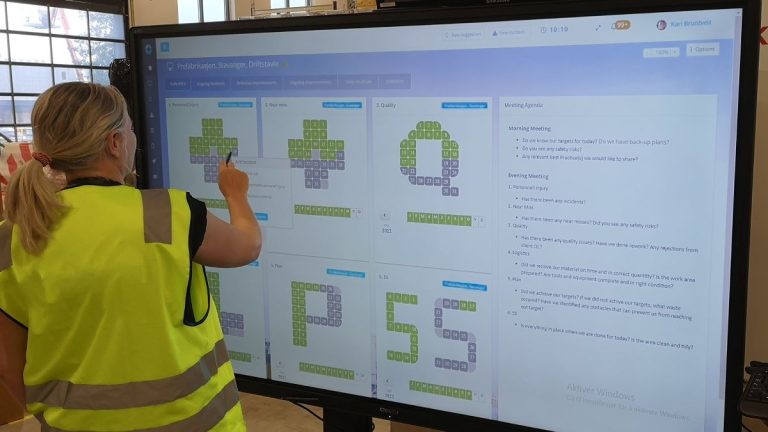

Interactive boards. Fully customizable.

Capture, prioritize and follow up improvements.

Report and manage incidents. Visualize reports and statistics.

Operationalize your strategies and integrate your whole organization.

Access your tools in Microsoft Teams.

Customized templates. Problem solving, business development etc.

Manage project individually or in portfolios with visual and interactive tools.

Create and share best practices, one-point-lectures and standards.

Easy access to tasks, improvements and incidents.

Integrate DigiLEAN with your existing IT systems.

Meeting the demand of larger organizations.

High security level by default.

In less than 4 min

Interactive tools for both shop floor and administration.

Visual project management.

Maintain standards. Manage incidents and discrepancies.

Manage tasks, integrate with problem-solving and continuous improvement.

Lean daily management tailored for healthcare.

We have a LEAN solution for you too. Just ask!

We meet the demand of larger organizations.

What is Toyota Kata?

Kata definition.

Kata is yet another Japanese history. It translates to “mold” (型) or “shape” (形) and is used as a training method in martial arts where they practice and perfect routines and movements. The idea is to internalize behavior so they can be used and adapted for different purposes with less effort.

The Toyota Production System

Toyota is the other part of Toyota Kata. Again, we turn to Japan and Toyota car manufacturer. They developed a production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most effective methods . This is referred to as Lean Manufacturing System and Just-in-Time production.

The Toyota Kata

Just like the Kata is used in martial arts, Toyota developed this approach to build and strengthen the organization’s problem-solving capabilities. Toyota Kata is not a problem-solving tool, but it’s a methodology to become a learning organization.

The Toyota Kata helps the organization to become more agile, innovative and to solve problems. It works with the mindset to increase the speed of learning.

Toyota Kata is divided in two main categories: Improvement Kata and Coaching Kata.

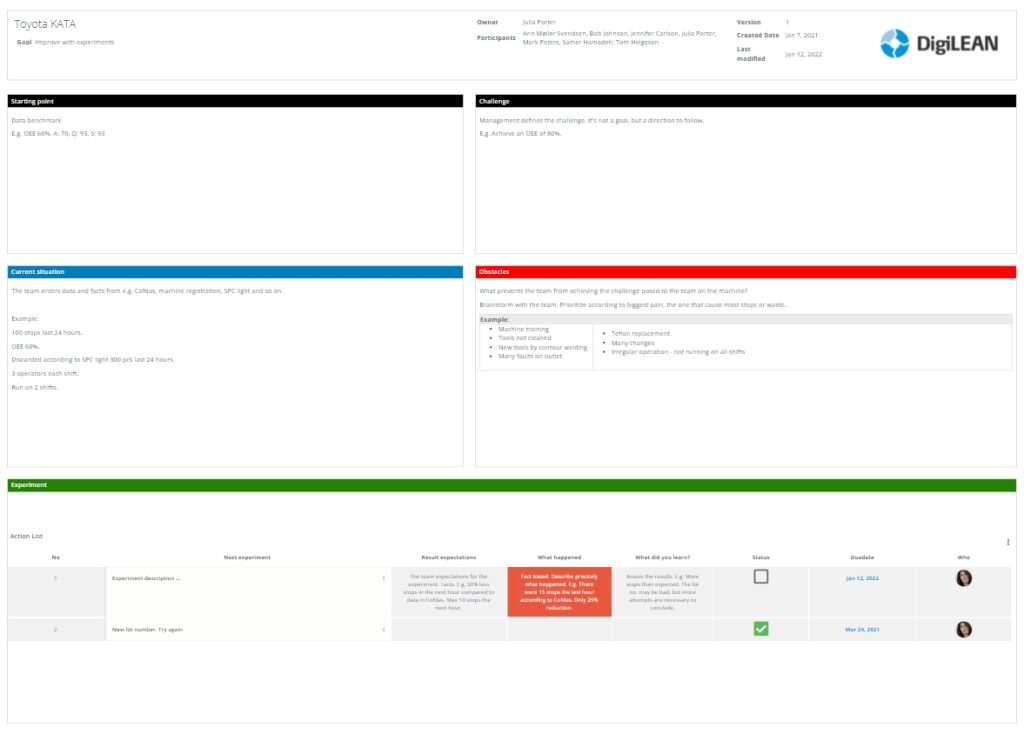

Improvement Kata

The Improvement Kata is for individuals to move from the current state to the desired condition. This is done by using the four Improvement Kata steps:

- Understand direction of change: To know where you are heading, you must set the direction. Define your vision to help keep an eye on your bearings.

- Grasp the current situation: You cannot develop a route or solutions without knowing where you are. Looking at a map, you are going from point A to point B. Fully understanding your current situation is point A.

- Establish next target condition: Based on the current situation and the direction of change, you define your next target condition. This is one step in the direction of your vision.

- Experiment towards target condition: Define actions you believe will lead you to the target condition. A dynamic action list is very helpful where you can describe your hypothesis and expected outcome. After a certain time, you will evaluate if the change gave the necessary results, or if you need to adapt and try again. This is an iterative process using PDCA on these experiments.

Coaching Kata

This is the ongoing process between the person performing Improvement Kata and his coach. Both operators, supervisors and managers can use Coaching Kata with their respective coaches.

The purpose with coaching kata is to build and strengthen the employees’ capabilities to solve problems and make improvements. Remember, giving answers straight forward does not built the employees capabilities. Reflection and individual practice do.

It’s a regular exercise for the mind, practicing Kata. The employee and the coach do a weekly one-to-one session of approximately 20 minutes where they reflect on the five following questions:

- What is the target condition?

- What is the current condition?

- Any problems? What is being done?

- What is the next step (PDCA)?

- When can we see what has been learned?

Benefits of Toyota Kata

- Develop skills

- Strengthen Lean culture

- Built problem solving capabilities

- Practice continuous improvement mindset

- Create innovation and organizational development

Using this methodology helps establish and strengthen lean thinking, innovation culture and adds problem solving capabilities to your organization.

A3 is a good tools for your Kata process

A3s, with templates for both Improvement Kata and Coaching Kata is a suitable formatted tool to help you document and structure the kata process.

Book a live demo to see it in "real" life.

Get the app.

© 2024 DigiLEAN AS

This page uses JavaScript. Please make sure that JavaScript is enabled in your browser.

- kanban library

- pricing & sign up

Thank you! We have sent you an email with details about your accounts.

- Kanban Guide

- Introduction

- History of Kanban

- Agile Framework

- Kanban Fundamentals

- ⬞ Visualize the Workflow

- ⬞ Limit Work in Progress

- ⬞ Manage Flow

- ⬞ Make Policies Explicit

- ⬞ Improve Continuously

- Kanban Elements

- ⬞ Kanban Method

- ⬞ Kanban Card

- ⬞ Kanban Board

- ⬞ Kanban Software

- ⬞ Personal Kanban

- ⬞ Manufacturing

- ⬞ Business Management

- ⬞ Bottlenecks

- Lean Thinking

- ⬞ Lean & Kanban

- ⬞ Just-In-Time (JIT)

- ⬞ Lean Manufacturing

- ⬞ Theory of Constraints (TOC)

- ⬞ Water Spider

- ⬞ Hoshin Kanri

- ⬞ Toyota Kata

- ⬞ Lean Project Management

- ⬞ Lean Accounting

- Lean Methodology

- ⬞ 5S in Lean

- ⬞ Six Sigma

- ⬞ Gemba Walk

- ⬞ Poka-Yoke

- ⬞ The 5 Whys

- ⬞ Flowcharts

- ⬞ Fishbone Diagram

- ⬞ A3 Problem Solving

- ⬞ SIPOC (COPIS)

- ⬞ Design of Experiments

- Lean Metrics

- ⬞ Cumulative Flow

- ⬞ Cycle Time

- ⬞ Lead Time

- ⬞ Process Throughput

- ⬞ Root Cause Analysis

- ⬞ Takt Time

- Kanban Use Cases

What is the Toyota Kata?

The Toyota Kata concept was developed by Mike Rother . It is a way of managing teams, teaching them to adopt the methods used and perfected by Toyota .

In Japanese, kata (型) stands for a set of structured routine movements that a martial arts practitioner would deliberately engage in to ensure that specific moves become their second nature.

Why is Toyota Kata needed?

Mike Rother noticed that while there were plenty of companies besides Toyota achieving high levels of success with Lean, other companies were less successful. He suggested that although those other companies attempted to embrace Lean on the surface, leaders and staff did not change their core ways of thinking & acting.

In observation of several Lean initiatives and projects, he noticed the following:

- Companies start their Lean implementation with lots of excitement

- Some progress is achieved at the beginning, but the end target state is not reached

- Subsequent desired results are not fully achieved

- Companies return to their homeostasis, and their former way of operating

- Employee thinking and mindset does not change

Rother developed a systematic way of practicing Lean. One, that encourages leaders and employees to effectively change their thinking and behavior, as opposed to only going through the motions of a set Lean initiative.

The Toyota Kata concept distinguishes an Improvement Kata and a Coaching Kata .

Improvement Kata

The Improvement Kata is a way of practicing scientific thinking through the use of set goal-oriented, problem-solving routines. It has 3 phases:

- The planning phase in which you determine where you want to get to, where you are currently, and what is the next step to take you closer to the goal.

- The execution phase in which you execute the plan and learn from it. This phase consists of many small experiments - as you hit roadblocks and overcome challenges, you learn what works and what does not. The goal is to deal with the problems that arise until the path to achieving your desired outcome is clear.

- The adaptation phase is the final phase, in which you look back at the overcome obstacles and adapt your plan and execution for the next cycle.

The Improvement Kata bases on the deliberate practice of a doing - feedback - adjustment loop. The most important part is identifying where you’re going wrong and discovering ways to improve that weakness. For example - a karateka who keeps dropping their hands during a fight would need to practice constantly keeping their hands up. In the same way, a software engineer who never tests their code could design a daily practice that would keep reminding them to test the solution before they deploy it.

Coaching Kata

For kata - a routine, an order of working - to exist, there has to be someone performing an activity and someone observing, reviewing, and providing direction on it. That is where the leader comes in, coaching their team members, preventing them from subconsciously reverting to old ways of working. Through their objective perspective, the coach also prevents the team from basing new habits on bad practices.

In the same way, that team members aren’t used to deliberate improvement practices; leaders are often not well versed in guiding employees’ improvement. Therefore, Coaching Kata exists to help leaders mentor their teams.

A coach can conduct 20-minute improvement sessions to ask questions that determine how the employee is currently thinking. They should also help the employee take the next step to optimize their growth and provide feedback on processes in their daily work. To check whether they are evaluating their performance correctly. A coach may also guide the employee through the learning process and ensure that they’re constantly practicing their kata.

| The five questions that the coach constantly reviews with the employee are: |

|---|

| What is the target condition, as related to the current state? |

| What is the current situation? |

| What do you think is preventing you from achieving the goal? |

| What next step will you implement? |

| How quickly will we be able to review what we’ve learned from this next step? |

How to use Toyota Kata for employee improvement?

Step 1: analyse the value stream.

Create a value stream map of the target process that you want to achieve. It will clearly express your vision and the benefits for the company to the employees you coach.

Did you know?

A Kanban Tool ® board is a handy aid in a flexible value stream visualization. Show the value streams as board stages as - as you start to understand the process better - adjust them anytime, all the while involving the rest of the team in the mapping, getting their comments and views on the shared project board. Try it out for free! Please enter valid URL This name is not available Please enter valid email address

Step 2: Reflect the goal on the current state

Look at the current value stream map with the employee and notice the differences between what it is and what you want to make it.

Step 3: Set the goal

Set short-term goals, naming the recommended steps and practices they have agreed to implement to reach their target.

Step 4: Monitor progress regularly

Have a 30-minute discussion with them every week to catch up on their progress and conclusions. Review their short-term progress once a month and sum up general status once every six months. It can be a good idea to provide rewards and incentives for achieving monthly and six-monthly targets.

Step 5: Do an annual review to reinforce the new habit-creating mindset

At the end of the year, review the employee’s performance based on their achieved goals, growth, and new habits formed.

The Toyota Kata can bring a new, dynamic way of guiding team members to improvement that far surpasses the typical OKR (Objectives and Key Results) environment of western managerial practices. In conjunction with what a company Hoshin Kanri program outlines, leaders can ensure that employees are growing and improving, adding to the company’s overall Lean goals. Furthermore, team members can look back and be satisfied with their new habits and a newly achieved mindset, making it more likely they will meet their next year’s goals too.

Toyota Kata & Kanban

It’s been said , that Toyota Kata is the perfect addition to a successful Kanban implementation, making for a truly Lean process . That is because the Kanban process cannot be tricked into showing you conditions other than the actual ones.

Kanban will also make it easy to gradually implement changes through its explicit policies and WIP limits . It will continuously measure your progress throughout the changes, making it clear whether the team has or has not mastered their kata.

How is Toyota Kata different from Kaizen?

Both of these concepts refer to process and performance improvement. The difference between them boils down to their methods or lack thereof. A continued effort to spot an improvement opportunity in your environment and take it would be engaging in Kaizen . But a more scientific, problem-solving, methodic approach to defining a problem and making a plan to eliminate it would be an implementation of Toyota Kata.

In many cases, the two ideas will overlap, and there is nothing wrong with that. In the end, the goal is always one: to make a change for the better. Some changes, e.g., those to complex processes relying on fluctuating decision-making, will be better to approach and measure methodically. Others, e.g., a one-time improvement to communication flow between team members, can be achieved instantaneously and be classified as a small Kaizen event.

Did you like this article?

Anything to change or improve - let us know.

Further reading

- Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results (BOOK)

- Kanban Tool

- Pricing & sign up

- Kanban Tool On-Site

- Kanban Library

- Kanban Tool Support

- Integrations

- Developer API

- Terms of service

- Privacy policy

© 2009-2024 Kanban Tool ® by Shore Labs . All rights reserved. | All other trademarks, logos and images mentioned on this site belong to their respective owners. | We use cookies on our website.

Kanban Tool is a visual management solution that helps companies visualize workflow, track project progress, and analyze and significantly improve business processes. Kanban Tool provides powerful online Kanban boards with seamless time tracking and insightful analytics. Our Kanban software works perfectly in any business process and is designed for teams that want to visualize work on a Kanban board .

- > What is Toyota Kata?

What is Toyota Kata?

Posted by Maggie Millard

Aug 18, 2014 1:41:00 PM

Well, for starters, a kata is a small, well-structured protocol or routine that becomes second nature through practice. The point of the kata is to acquire the habits of thought and action through practice, rather than to just memorize the routine. And, a kata makes these skills transferable to others, which is an important part of developing a sustained culture of continuous improvement within an organization.

Toyota’s improvement processes come from two fundamental kata - the improvement kata (or problem solving) and the coaching kata.

The Toyota Problem Solving Kata:

The Toyota problem solving kata encourages working on single issues and single countermeasures in rapid succession. Operating this way increases the organization’s knowledge and understanding of that process. The goals of this kata are to learn about the system itself to fully understand the situation, and to apply only one countermeasure at a time (so that you can accurately identify cause and effect).

The Toyota Coaching Kata

At Toyota, leaders offer guidance for solving problems in the correct ways, helping to develop employees’ problem solving skills. In this way, it is the team members, not the supervisors, who find the solutions to problems. Most improvement efforts are “bottom up,” relying on and improving upon each employee’s knowledge base.

There are two main duties of a leader under these kata:

- Respond At the first sign of an issue, a leader must respond and take ownership of the problem. The first response is to institute a short-term countermeasure - this allows work to continue unimpeded while a more permanent solution is identified and implemented. It is during this pursuit of the best solution that the coaching kata becomes invaluable.

- Understand An organization relies on its employees fully understanding their work processes. When a problem arises, it reveals some missing information about the process. Understanding the origin of the problem and its effect on other areas of the organization will enable better problem solving and increase the profound knowledge of the organization as a whole.

See how KaiNexus customer Michael Lombard uses Toyota Kata at his organization:

Click here to see how KaiNexus helps Michael with his Toyota Kata efforts!

Add a comment, subscribe via email, recent posts.

Why KaiNexus

- Collaboration

- Standardization

- Customer Success Manager

- Lean Strategy

- Solutions Engineering

- Customer Marketing

- Configuration

- Continuous Enhancements

- Employee Driven

- Leader Driven

- Strategy Development

- Process Driven

- Daily Huddles

- Idea Generation

- Standard Work

- Visual Management

- Advanced ROI

- Notifications

- Universal Badges

- Case Studies

- Education Videos

Copyright © 2024 Privacy Policy

An official website of the United States government

Here’s how you know

Official websites use .gov A .gov website belongs to an official government organization in the United States.

Secure .gov websites use HTTPS A lock ( Lock A locked padlock ) or https:// means you’ve safely connected to the .gov website. Share sensitive information only on official, secure websites.

https://www.nist.gov/blogs/manufacturing-innovation-blog/toyota-kata-lean-strategy-keeping-pace-change

Manufacturing Innovation Blog

Powered by the Manufacturing Extension Partnership

Toyota Kata: A Lean Strategy for Keeping Up with the Pace of Change

“Why are our changeovers taking so long?”

If you’ve asked this question on the shop floor, more than likely you were met with blank stares by your employees. Open-ended questions like this are overwhelming, so employees try to find quick answers that don’t really address the problem. They don’t have a starting point to form an answer.

But what if you asked a question with a specific, achievable goal?

“What steps can we take to reduce changeover time by 15 minutes?”

You’ve then provided your employees with a measurable goal in the form of a question. Your workers may feel empowered to answer with some hands-on suggestions for incremental changes, such as reducing setup steps or combining workstations. This in turn could not only reduce changeover time, but significantly eliminate wait times and inventories.

This approach is often described as Kaizen, or “continuous improvement,” which serves as the backbone for lean manufacturing . Kaizen uses the Plan, Do, Check, Act (PDCA) problem-solving cycle to encourage manufacturers to use small ideas to solve big problems, such as costly, time-intensive changeovers.

These methodologies are the building blocks of Toyota Kata , an innovative, lean way of thinking described in the book by Mike Rother, “Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results.”

In essence, Toyota Kata goes beyond problem-solving to teach management, engineers, and operators a new mindset to develop their creative and scientific-thinking skills to make them more effective, lean manufacturers. This approach looks at lean manufacturing as a culture, rather than a single process.

With the world of manufacturing evolving at a breathtaking pace thanks to developments such as Artificial Intelligence (AI), labor skill gaps, and the Industrial Internet of Things (IIoT) , Toyota Kata gives smaller manufacturers a lean strategy to help them grow with these developments. It empowers employees with the skills they can use to continuously improve, adapt, and generate ideas for a strategic, competitive advantage.

Small Steps Lead to Big Results for Manufacturers

Toyota is known as the most successful early adopter of Kaizen and the originator of the “continuous improvement” philosophy for manufacturers as part of its innovative Toyota Production System . This approach helped the company create vehicles famous for their reliability, while eliminating production waste, time, and energy resources. Toyota’s “plan slowly and act quickly” philosophy helped create the Prius hybrid, which positioned the company as the leader in hybrid technology. More than 80 years after the company’s founding, Toyota is the world’s largest automaker .

Toyota Kata builds on Toyota’s “continuous improvement” success model, so other manufacturers can learn from its example. This approach has become increasingly popular with manufacturers who want to move beyond short-term production goals to empower their workforce to implement daily, sustainable process improvements.

In Arkansas, Almatis Premiun Alumina had previous experience working with lean tools and using those tools in the traditional point solutions approach that led to obvious improvements and positive results. The challenge was to sustain continuous improvement. The company was interested in revitalizing its lean efforts and pursuing sustainability. Almatis contacted the Arkansas Economic Development Commission – Manufacturing Solutions (AEDC-MS), the MEP Center in Arkansas, for assistance.

AEDC-MS sought to create a program that would target bottom-line improvements through process cost reductions. A team of 18 people identified, managed and capitalized on opportunities within the manufacturing process. AEDC-MS led eight hours of Lean 101 training, including introductions to the Improvement Kata. Then, the team used leadership coaching to focus on individual responsibilities, human nature’s tendency to oppose change and exposure to the scientific process of continuous improvement. Sixteen hours of Value Stream Mapping was used to address the needs of a specific manufacturing line and office activities. Extra time was spent with the Almatis management team to assure they were ready for Kata delivery. A three-day Toyota Kata session led to a $12,000/month savings in the first two days of implementation, providing a full return on investment within the first 30 days of improvement.

Other results achieved included:

- $2.5M in increased or retained sales over one year

- 160 new or retained jobs

- $200,000 in cost savings

- $475,000 in new investment

How to Integrate Toyota Kata Within Your Facility

To help small and medium-sized manufacturers achieve lean success like Almatis and Toyota, the MEP National Network TM has developed a Toyota Kata overview: Toyota Kata: Developing the Skills to Thrive in Today’s Constantly Changing Marketplace .

This overview highlights that, while smaller manufacturers may not have the level of strategic resources like the behemoth Toyota, they can apply the same methodologies of Toyota Kata, including:

- Developing new habits and allowing people to think differently about problems and goals

- A way of working, and of working together

- Using scientific thinking as an ingredient to make teams and organizations more effective and successful

- Developing a culture of continuous learning and improvement at all levels through deliberate practice

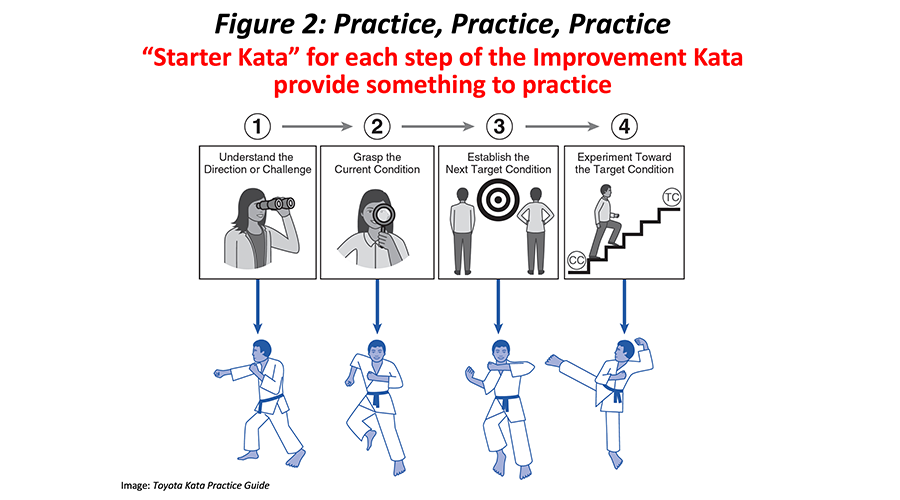

Implementation of Toyota Kata begins with the aptly-named Starter Kata. Starter Kata focuses on small protocols and processes that, when practiced early and often, help manufacturing employees learn faster and teaches them to work more collaboratively. The two main elements of Starter Kata are Improvement Kata and Coaching Kata, as noted in the above Almatis example.

The Improvement and Coaching Kata help employees:

- Understand the direction or challenge

- Grasp the current condition

- Establish the next target condition

- Experiment toward the target condition

By integrating Toyota Kata as part of your manufacturing best practices, your employees can successfully overcome obstacles and develop more confidence and scientific thinking to solve problems.

The MEP National Network’s overview of Toyota Kata is a first step to empowering your workforce to become more agile, so they can find new ways to cut waste, develop new technologies, and adapt to these new changes in the ever-increasing competitive world of manufacturing.

About the author

Brian Lagas

Brian Lagas manages NIST MEP's Continuous Improvement, Toyota Kata, Sustainability and Export initiatives.

Related posts

Tap into a new talent pool to fill your workforce gaps: Second chance citizens

The MEP National Network’s Supply Chain Optimization and Intelligence Network: Helping Manufacturers Bridge Gaps

Leading the MEP Program – and Giving Back to this Land of Hope and Promise

Add new comment.

- No HTML tags allowed.

- Web page addresses and email addresses turn into links automatically.

- Lines and paragraphs break automatically.

Toyota Kata

What is a kata.

A kata is a small, well-structured protocol or routine that becomes second nature through practice, and brings about the development of a particular skill. The point of the kata is not the memorization of the routines, but rather is the habits of thought and action that practicing them leaves behind.

In other words, a kata is a means for the acquisition of new cognitive and behavioral skills, such as process improvement. Furthermore, a kata make these skills transferable to others - an essential part of developing a sustained culture of continuous improvement within an organization.

How does Toyota use kata?

Toyota’s improvement processes arise from two fundamental kata - the first is for improvement or problem solving, the second for coaching.

The Toyota Problem Solving Kata

A common, but flawed, strategy for problem solving involves taking on complex problems and tackling many issues simultaneously. This approach makes it difficult to understand which strategies and techniques worked and which did not, as too many changes are made simultaneously.

Conversely, the Toyota problem solving kata encourages working on single issues and single countermeasures in rapid succession. Operating this way increases the organization’s profound knowledge and understanding of that process.

The goals here are twofold:

1. Learn about the system itself and come to fully understand the situation

2. Observe the situation, applying only one countermeasure at a time so that cause and effect becomes apparent.

What's more, as each countermeasure is applied, it reveals the next problem and the improvement process can quickly proceed.

The Toyota Coaching Kata

Most companies have some version of a performance management system in which a team member develops a set of goals with his supervisor and is evaluated at the end of the time period on his performance in meeting those goals. However, this is more authoritarian than collaborative, leading with pressure rather than coaching.

At Toyota, a process of mentoring replaces this outdated leadership style. Leaders offer guidance for solving problems in the correct ways, helping to develop employees’ problem solving skills. In this way, it is the team members, not the supervisors, who find the solutions to problems.

With the Toyota coaching kata , most improvement efforts are “bottom up,” relying on and improving upon each employee’s knowledge base. Additionally, the entire operation is reliant on problems being flagged immediately. This allows most problems to be discovered and solved when they are still small, rather than waiting until they set off a chain of failures and subsequent problems.

There are two main duties of a leader under these kata:

- Respond At the first sign of an issue, a leader must respond and take ownership of the problem. The first response is to institute a short-term countermeasure - this allows work to continue unimpeded while a more permanent solution is identified and implemented. It is during this pursuit of the best solution that the coaching kata becomes invaluable.

See how KaiNexus customer Michael Lombard uses the Toyota Kata in his organization:

Michael lombard.

Director of Operational Excellence at a Hospital in the Dallas-Ft. Worth Area

In this video, Michael says...

When I came in as Director, we were kind of starting with a blank slate, so we had the opportunity to do some research. We started looking at some videos by John Shook of the Lean Enterprise Institute, and he talks about two pillars of CI: one being process improvement, the other being developing the capacity of your organization - giving them skills and competencies, and you want to be able to do both at the same time.

We came across the Toyota Kata method to continuous improvement, and it really does help fulfill both of these pillars at the same time. So we adopted that about a year ago and we've been experimenting just to see what works and what doesn't, and it works really well. Clinicians love it, it appeals to their action oriented nature, it allows them to just try things and learn from it and take steps forward.

Really, our next step with the Toyota Kata approach is going beyond our initial cadre of coaches, and infiltrating all levels of the organization. We're starting so see a pretty good spread (we track that sort of thing - how many departments we're doing coaching in, how many departments we're doing PDCA cycles in). But we really need to take it to that next level and start engaging everybody in the organization, from the clinical staff to the physicians, to the nonclinical staff and the leaders.

Recommended reading:

Toyota Kata (Mike Rother)

Gemba Academy Podcast with Michael Lombard discussing Kata

Toyota Kata : Lean Enterprise Institute

Why KaiNexus

- Collaboration

- Standardization

- Customer Success Manager

- Lean Strategy

- Solutions Engineering

- Customer Marketing

- Configuration

- Continuous Enhancements

- Employee Driven

- Leader Driven

- Strategy Development

- Process Driven

- Daily Huddles

- Idea Generation

- Standard Work

- Visual Management

- Advanced ROI

- Notifications

- Universal Badges

- Case Studies

- Education Videos

Copyright © 2024 Privacy Policy

Mastering Problem-Solving and Decision-Making Skills with Toyota Kata

Toyota Kata is a methodology developed by Toyota to help organizations achieve continuous improvement. At its core, Toyota Kata is a set of practices that help individuals and teams to develop and improve their problem-solving and decision-making skills.

The word “kata” refers to movements or techniques practiced repeatedly until they become ingrained in the performer’s muscle memory. In the context of Toyota Kata, the term refers to practices designed to help individuals and teams develop the skills they need to improve continuously.

So, how does Toyota Kata work? At its core, Toyota Kata is based on experimentation and learning. The methodology involves a four-step process:

- Understand the direction: The first step in the Toyota Kata process is understanding the direction or goal. This involves clearly understanding what you are trying to achieve and why it is important.

- Grasp the current condition: The second step is to grasp the current condition. This involves clearly understanding the current situation and identifying any obstacles or challenges that must be overcome.

- Establish the target condition: The third step is establishing the target condition. This involves developing a clear vision of where you want to be and what you must do to get there.

- Conduct experiments: The fourth step is to conduct experiments. This involves testing different approaches and solutions to see what works and what doesn’t.

The Toyota Kata methodology is designed to be used on an ongoing basis. By following this process, individuals and teams can continuously experiment and learn, improving their problem-solving and decision-making skills.

So, what are the benefits of using Toyota Kata? One of the key benefits is that it helps to establish a culture of continuous improvement. By encouraging experimentation and learning, Toyota Kata helps create an environment where individuals and teams constantly look for ways to improve.

What do I get out of practicing KATA?

We gain a new meta-skill with frequent training to apply in all possible situations. Here are some examples:

- Improved adaptability to increasingly complex and dynamic situations.

- True daily continuous improvement becomes part of our business.

- Increased likelihood that we discover innovations through improved problem-solving skills.

- A way of leading includes an organic way of building a learning organization.

- The ability to learn new skills faster. 6) Find unique solutions to unique challenges.

Another benefit of Toyota Kata is that it helps to develop the problem-solving and decision-making skills of individuals and teams. By practicing the Toyota Kata techniques, individuals and teams can improve their ability to identify problems, develop solutions, and make decisions.

In conclusion, Toyota Kata is a powerful tool for any organization seeking continuous improvement. By following the four-step process of understanding the direction, grasping the current condition, establishing the target condition, and conducting experiments, individuals and teams can develop the problem-solving and decision-making skills they need to succeed. With its emphasis on experimentation and learning, Toyota Kata helps to create a culture of continuous improvement and sets organizations on a path to long-term success.

- More By sensei

- More In Blog

Enhance Your Equipment Reliability with Preventive Maintenance

Project Management Career Paths and Certifications: What You Need to Know

A Four-Step Guide to Reducing Maintenance Expenses

Essential Quality Tools for Effective Process Improvement

Achieving Manufacturing Excellence: The Right First Time Approach

Enhance Efficiency with These Key Maintenance Scheduling Strategies

Mastering Quality Department KPIs: A Comprehensive Guide

Maximize Efficiency with the Right Plant Layout: A Comprehensive Guide

Harnessing Business Excellence in Manufacturing Through the PDCA Approach

How to Ace Your Next Job Interview: Expert Insights and Strategies

Mastering the Trio: Project, Program & Portfolio Management

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Most Popular

4M Analysis Process

The purpose of this procedure is to define the steps to do a 4M …

PDCA – A Process Approach

OPL – One Point Lesson Template – Free Download

5S Audit Checklist and Report

Why-Why Analysis

Blog Search

- Terms of Use

- Privacy Policy

- About Our Ads

The Lean Post / Articles / How the Toyota Way and Toyota Kata Fit Together

Executive Leadership

How the Toyota Way and Toyota Kata Fit Together

By Jeffrey Liker

March 18, 2022

The author of The Toyota Way explains where Toyota Kata fits with Toyota’s broader management principles — and how each enhances the other to help you build more effective organizations.

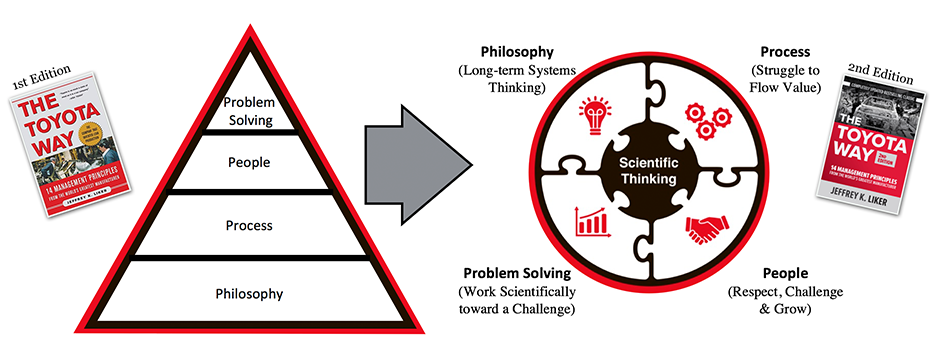

Recently, I’ve noticed some confusion about the relationship between the Toyota Way and Toyota Kata . So, with the publication of the second edition of my book, The Toyota Way , I want to clarify the differences.

The Toyota Way and Toyota Kata are management concepts described in well-known books that reveal the thinking and practices underlying the company’s success. The Toyota Way summarizes the management system Toyota has evolved over the last century as a set of fourteen principles. Toyota Kata describes the practice routines Mike Rother developed to aid people in getting started developing the habit of scientific thinking he saw as central to Toyota’s success.

The term “scientific thinking” can be confusing and might spark the picture of a lone scientist sitting in the lab conducting some fundamental research and developing abstract models. However, in lean management and problem-solving, scientific thinking refers to the mindset and practices that enable people to achieve challenging goals. In teaching and coaching scientific thinking, lean practitioners, then, are trying to develop people’s “practical scientific thinking” skills, which will help enhance their problem-solving capabilities.

These were written about in different books and are often practiced as though they are different schools of thought or approaches to lean transformation. So the question is: Are these two systems compatible, or do we have to choose to believe in one or the other?

I have had an insider seat to both since I have been studying Toyota for about 40 years, and Mike was my graduate student at the University of Michigan and lives close by. So we regularly have long discussions about these topics.

My overall conclusion is that while I was deriving general management principles from my learning about Toyota, Mike was delving into a practical approach to one of the core aspects — problem-solving through scientific thinking.

Mike’s model of scientific thinking — the Improvement Kata Pattern — was derived from watching some of the best Toyota Production System (TPS) masters in Toyota at work . He then went beyond the conceptual model to help others learn how to do this themselves through an age-old approach to mastering complex skills — deliberate practice with a coach!

Integrating The Toyota Way and Toyota Kata

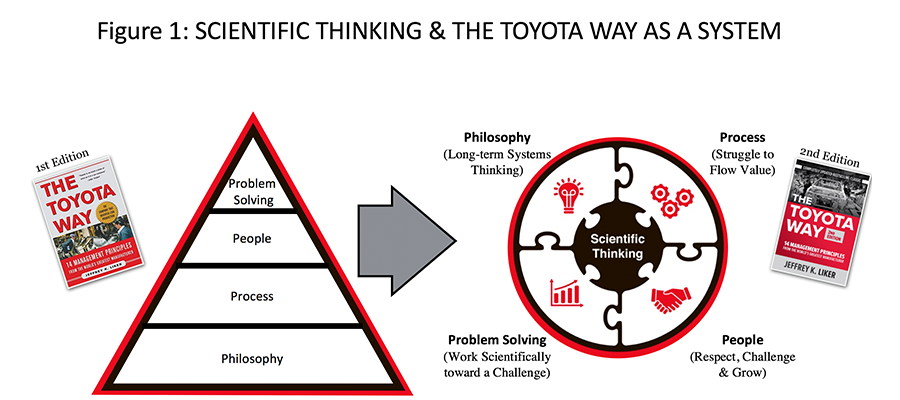

Based on my long discussions with Mike and some soul-searching myself as to where this all fits together, I changed the foundational 4P model of The Toyota Way to place scientific thinking in the center ( see illustration below ).

In the first edition published in 2004, I had represented the model as a pyramid, placing philosophy as the foundation and problem-solving at the pinnacle. At that time, it had seemed that scientific thinking should be a part of problem-solving. However, after thinking more about it, I made two significant changes to the model for the 2020 second edition:

- I changed the model to a set of interconnected puzzle pieces to show that all the components are interrelated — a system.

- I put scientific thinking at the system’s center after concluding that all the principles are more effective with a scientific approach. For example, though the process principles seem to lead to a straightforward implementation of tools, like a work cell , they don’t. Instead, with a scientific approach, you start with a vision or objective, such as achieving one-piece flow of value to customers. You then experiment with ways to work toward this vision, continually learning and refining your process .

Seeing Scientific Thinking in the TPS

While “scientific thinking” may seem new and perhaps theoretical, it is consistent with Toyota’s teachings, going back to the first TPS manual by Taiichi Ohno: “On the shop floor, it is important to start with the actual phenomenon and search for the root cause in order to solve the problem. In other words, we must emphasize getting the facts.”

One of Ohno’s students, Hajime Ohba, later explained in a public presentation: “TPS is built on the scientific way of thinking … How do I respond to this problem? Not a toolbox. [You have to be] willing to start small, learn through trial and error.”

In his excellent 2004 Harvard Business Review article on “ Learning to Lead at Toyota ,” Steven Spear discusses the rigor with which Toyota trains all its managers to be scientific thinkers: “Trainees watch employees work and machines operate, looking for visible problems… Learners articulate their hypotheses about changes’ potential impact, then use experiments to test their hypotheses. They explain gaps between predicted and actual results… Supervisors act as coaches, not problem solvers. They teach trainees to observe and experiment.”

Compare this with Rother’s description of the basics of practical scientific thinking for the rest of us who are not PhD scientists:

- Acknowledging that our comprehension is always incomplete and possibly wrong.

- Assuming that answers will be found by testing rather than just deliberation.

- Appreciating that differences between what we predict will happen and what actually happens can be a useful source of learning and corrective adjustment.

Developing the Kata

Mike wanted to go beyond elucidating principles of scientific thinking, so he arrived at the approach of daily practice via kata . Kata in Japanese martial arts like karate are specific movements that the master teaches to the learner through demonstration and then watching the learner try, repeatedly, until the student achieves some level of mastery of that specific, building-block skill. This approach then leads to mastering the next kata, and next, and so on. Over time, the karate student moves from practicing individual kata to combining them as situationally demanded when fighting. Those who have seen The Karate Kid have seen kata in practice ; those who have watched a jazz band play have seen the results.

Those who have seen The Karate Kid have seen kata in practice; those who have watched a jazz band play have seen the results.

Mike provided us with the Improvement Kata and Coaching Kata — including a set of practice routines, or “Starter Kata,” for each stage of the model, which people can use to practice scientific thinking deliberately.

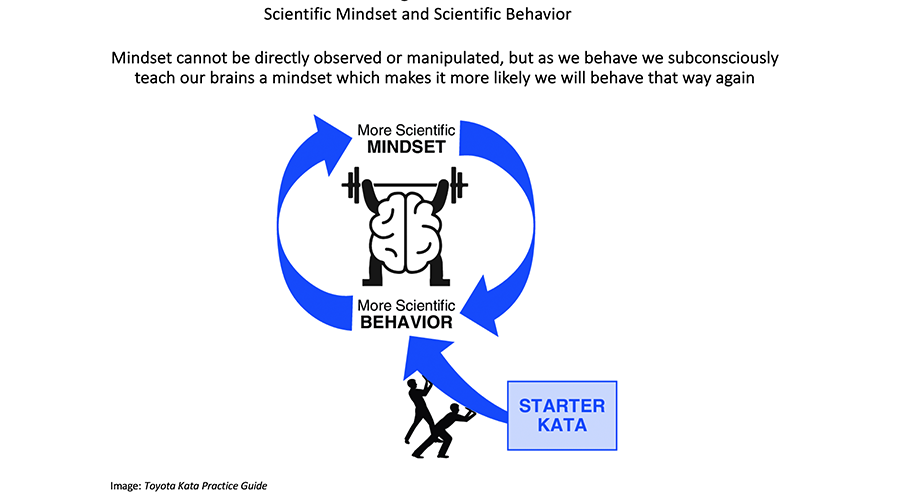

Having a way to practice scientific thinking is critical to counter our natural “problem-solving” instincts. All of our skills and ways of thinking occur in our brains. Routine actions like maneuvering our car are bundles of connected neurons that we can call up, somewhat like computers call up subroutines. However, the problem is our natural subroutines for solving problems program us to quickly imagine solutions before deliberately thinking through the problem definition and understanding the current condition.

The Lean Community has offered various methods to prevent this jumping-to-conclusions instinct, such as systematically stepping through the plan-do-check-act ( PDCA ) process. However, neither telling people to do this nor several-day problem-solving workshops are enough to create new, counter-intuitive neural circuits.

It is tempting to try to devise a way to flush our minds clean of these old thinking habits, but what is in our brain does not in any natural way get wiped as we can do to a computer’s memory. Instead, we must build new neurological structures that, when strengthened through practice, become our go-to for addressing problems. The old well-worn ways of fast thinking start to fade into the background since we do not use them, and the new slow-thinking patterns start feeling more natural. We are practicing, or should I say “deliberately practicing,” a new way and in doing so rewiring our brains.

Creating Daily Habits of Deliberate Practice

Toyota teaches practical scientific thinking to each manager, beginning when they are hired, and coaches reinforce the practice daily. But the rest of us need some regimen to practice deliberately. Mike’s Improvement Kata serves this purpose ( See illustration below ).

In total, the Improvement Kata starts with a clear purpose in the form of a measurable challenge, and then we iteratively learn our way to the challenge. The starting assumption is that we do not know how to meet the challenge because of too much uncertainty. So we have to step our way through it experiment by experiment, adjusting and learning as we go. Most people are uncomfortable not knowing, accepting uncertainty, and recognizing that the future is not predictable. Therefore, we need to practice our reactions when confronted with such situations, ideally with a coach.

The emphasis in Toyota is on learning by doing . Toyota values theory, but as a basis for developing practice through experimenting.

Now, we all know the emphasis in Toyota is on learning by doing. Toyota values theory but only as a basis for developing practice through experimenting. To make this scientific-thinking pattern gel in our minds, we need enough practice to create strong neural pathways.

Understanding the Neuroscience of Learning

We also know that there is a limit to how much new input our brains can absorb in one session, and it’s less than you might think. Twenty minutes seems to be about right. Practicing for short periods daily for several months is much more impactful than morning-to-night sessions that we might have in an executive immersion training course or a one-week kaizen event.

Neuroscientists have demonstrated that behavior and thinking are interconnected (s ee illustration below ). When we do something, that information gets encoded as a bundle of neurons and synapses that connect the neurons. When we practice a particular way, we get a very efficient circuit that becomes our habit. So, for example, if we approach a problem through fast thinking, jumping to conclusions, we are more likely to address issues. To counter that tendency, we need to behave scientifically repeatedly, which will change how we think and make us more likely to approach problems that way in the future.

When you put this all together, you get the Improvement Kata model and its associated practice routines done in a coach-learner relationship. Toyota seems to do it naturally without a lot or scripting of how the coach teaches the student. Mike has made it explicit and more structured in Toyota Kata to help those who are not already in a mature organization with a culture of scientific thinking.

Does Toyota Kata Replace the Toyota Way?

Does this mean that Toyota Kata now replaces the Toyota Way since scientific thinking is at the center? Certainly not. The 4Ps of the Toyota way reflect a management system that is more than individual people thinking scientifically. It starts with a collective clarity of purpose and core values that guide the overall enterprise. What is the organization’s purpose? What is the collective vision for how we want the enterprise to operate? This system must be lived and modeled by all managers to become the guiding force of the culture.

The Toyota Way starts with a collective clarity of purpose and core values that guide the overall enterprise.

Philosophy does not emerge from experiments but needs to be carefully thought through and embraced to help provide direction to specific improvement efforts. Similarly for Process, there is a body of knowledge about lean processes and moving toward one-piece flow that you are not likely to discover through experimentation within a mass-production system. As a result, we need to develop people’s capabilities in many ways besides scientific thinking to get to the leadership and culture we desire. Problem-solving is best done with a scientific mindset and includes ways to align goals ( hoshin kanri ) toward a clear strategy for the products and services of the firm.

We should also recall that Mike calls these “starter kata” rather than “finishing kata.” So, he does not intend for people learning scientific thinking to continue forever to follow the “starter kata” precisely as if it were a new rigid method for problem-solving. Instead, they are for the student to practice — and develop — a scientific thinking mindset. Perhaps we can view the kata as a catalyst that juices scientific thinking, which, in turn, is the engine that drives the Toyota Way. Without it, or some equivalent way of developing people to think scientifically, the Toyota Way might remain at the level of principles without practice.

Editor’s Note: In case you missed it! This Lean Post is a lightly edited version of an article published in February 2021.

Improvement Kata/Coaching Kata

Develop Scientific Thinking, a Foundation of Lean Management in the 21st Century.

Written by:

About Jeffrey Liker

Dr. Jeffrey K. Liker is Professor of Industrial and Operations Engineering at the University of Michigan, owner of Liker Lean Advisors, LLC, Partner in The Toyota Way Academy, and Partner in Lean Leadership Institute. Dr. Liker has authored or co-authored over 75 articles and book chapters and eleven books.