The Danaher Business System Mindset

Former director at danaher corporation, inpractise.com/articles/ danaher-dbs-mindset, why is this interview interesting.

- A walkthrough of the Danaher Business System (DBS) process to solve problems

- Why the DBS is a mindset not a methodology

- Why other companies struggle to adopt a system similar to DBS

- Why no PowerPoints are allowed at Danaher

- How Danaher can apply DBS to intangible asset-based companies

The Danaher Business System Mindset ( October 23, 2020 )

Bruno meinhardt.

Bruno has over 20 years of experience in supply chain and logistics and is the Former Regional Director of Distribution for Europe at Danaher Corporation. He enjoyed over three years immersed in the Danaher Business System (DBS) as Head of Logistics for Leica Biosystems, a Danaher diagnostics operating company, and also as a member of the Transport and Logistics Leadership Team for Europe at Danaher. Bruno applied DBS to consolidate the logistics network in Europe between Leica and other platforms outside of diagnostics. He was also a Problem Solving Process (PSP) trainer who was responsible for training new recruits in how to detect and solve problems in the business. Bruno now runs a plant for MANN+HUMMEL, a global leader in filtration systems.

Interview Transcript

Bruno, can you share a short introduction to your experience and role at danaher.

I was with Danaher for more than three years, particularly working for Leica Biosystems in the cancer diagnostics platform. I was responsible for logistics and distribution, across EMEA, as a regional director. I was also been a member of the global T&L Steering Committee for all OpCos.

You were head of logistics, for Leica, but also involved in a European wide logistics team?

Exactly. When it came to Leica, in those days, Leica had a sales turnover of roughly one billion, with multiple sites, from Australia to China, Singapore and plenty of sites in Europe and the US, as well as Mexico and Canada. My sphere was EMEA.

Take me back to when you first joined Danaher. When you walked into the company, what was the training process like?

The training process was pretty interesting because, normally, all the Danaher companies had some kind of immersion plan. For me, when I arrived, from day one, I was on policy deployment, as we had the idea to transform the company. My task was to bring in the related cost reductions to finance the rest. My training was pretty limited but, for sure, over the time, I needed to do some mandatory courses such as the framework in the DBS, for example, or in the PSP environment.

What really surprised you about the culture at Danaher, when you first joined?

When I joined the company and also later on, what really surprised me was the fact that everything was really related to the Danaher Business System, to the DBS. The DBS is some kind of lean methodology, a bit like the one from Toyota. What really surprised me was that that this company was extremely focused on numbers and all the relevant consequences. Numbers talk. This was pretty new for me.

Why is the culture unique?

In my opinion, it is unique because no matter where anybody is in the company, everybody, whether he is a manager or department leader or even a President of a company, they have to learn the DBS system, or at least the basics and also apply the PSP problem-solving tool, as the language. This is unique. It goes from the strategy down to the policy deployment and down to the daily management, so it’s totally consistent. In my opinion, this is also unique, because what I have seen in other companies, in many industries, people have lots of indicators and matrices to deal with things, but they are not particularly closely related to each other.

Why don’t other companies set up a system similar to DBS if it works so well?

I think they feel the consequences. When you really do it like this and speak very strongly to the philosophy, over time, you also face some trade-offs. For example, when it comes to budgeting, the budgeting rule takes the P&L from last year and deducts 5%. But when you do this multiple times, with each round, things will become much more difficult. The DBS should help you to improve the productivity, but it only brings in the relevant results when you are able to use the people which may lead to a productivity increase, according to your growth. This is why growth is the engine and you need to have both. You need to have the growth approach and the DNA and then later on, you need to have the DBS. This is something that people fear.

Also, over time, as this company culture is really very restricted to numbers, it’s very simple. You don’t make the numbers, you get asked why, you need to undertake a problem-solving process, speak to the action plan and make it happen. Hopefully, you will make it happen, otherwise you will be out pretty quickly. For example, I was in this committee for all the different OpCos. We met twice a year and, in each meeting, I had about 40% of new people on board, because the pressure is super high on the numbers.

So they were pretty relentless on focusing on numbers and if you don’t hit your numbers, then you’re out the door?

When you don’t hit your numbers, you need to run a problem-solving process and find ways to make it happen, otherwise you will be sent, pretty fast, into poor-performance improvement. Normally, when you go into the process of poor-performance improvement, things become very, very difficult. What I have seen so far, people themselves then decide that this kind of company is not a meaningful one for them.

How would you describe that culture? How does it feel to be an employee?

This is a very difficult one because the different companies or the different sites are, more or less, brought together. Yes, each company and each site brings in its own culture. But over the years, and as they become part of a platform or part of a Danaher company, they start to lose this culture, because they have to embrace the DBS culture. The issue is, either you embrace it, or you exit. A lot of people like it and really like to become part of DBS because it is really cool to go for improvements. But the downside is, in the same situation, you need to grow. If you are not able to grow, you have a problem with all the process improvements because then you have a lot of people left over. Then you will need to go for lay-offs.

Does that create a lot of pressure for employees?

Yes, definitely. Every department, every OpCo, every site, every platform is running to around seven different key performance indicators and it is really broken down from the strategy to the policy deployment to the daily management. Everybody sticks to this, every single day. Certainly, one part of the DBS culture is also to make things transparent and to make things ugly. For example, we always said that red is the new green. We put some targets out and if you have reached the targets and you become green in all of them, we skip the targets, go to the next level so that, more or less, everything is red again. This brings a lot of pressure to the people and a lot of folks can’t really deal with this.

But I don’t think it’s so bad because you have constant improvement. It is also very dependent on the site leader or OpCo leader as to how you really deal with these things. They need to explain to the people that red is nothing bad, but it is a chance, an opportunity. Therefore, they really have to embrace the culture because, as they were brought together, they bring in their old culture and, in the old culture, red was something negative.

How are the employees incentivized, at the ground level, to really buy into this culture?

What I have seen so far is that they can be part of culture, as they learn the different tools, as they improve themselves. They can also do a lot of job rotations. But it is always related to results. When it comes to payment, everybody gets a bonus related to company results, on the one hand. On the other hand, people have to be developed. Every leader of every department or every manager of every department or OpCo site, needs to take care of their people and develop them, and document this in a consistent system. If they do not do it, they are really in trouble with their boss. On one side, this is pretty good but, on the other side, a lot of people don’t want to be developed. For example, a forklift driver in the warehouse, he comes here to do the job, get the money, goes home; that’s it. There is no fancy stuff. He does not want to become the new vice president of logistics. How are you going to develop people like this, or situations like that? Development was also mandatory for everyone.

The next issue is that Danaher did pretty well on a survey. Once a year, they conducted an anonymous survey, consisting of 50 to 60 questions, in different categories. Every manager was measured according to the results of this anonymous survey, with the clear task to improve various things. For example, when the engagement index was not very high, you got a clear message that you needed to improve the engagement index by a certain percentage. Although this was all anonymous, they had to find ways that by the next survey, their results improved significantly. You really needed to do this otherwise you were in trouble, your boss was in trouble and it went straight up, to the president of the platform.

It seems a very meticulous culture, with rigorous focus on numbers, outputs and performance, it leads to this continuous improvement mentality, which drives profitability and the quality of the company? How do you view the pros and cons of the potential high pressure and stressful environment versus the performance and the output?

In my opinion, this is when it comes to leadership. If you have the right people in place, with proper leadership skills, you can deal with this. I was in contact with a lot of different operation companies and sites, according to my role, and I saw very different set ups. There were set ups where you had very strong leaders, so the morale of the staff was pretty good and they could really deal with this in a supportive environment, where there were challenges, a bit like in sports. But I also saw some not so strong leaders. When you saw them, it was really painful because they had shirts on and, printed on the back of the shirt was Go to Gemba, but you never saw them in a production site or in a warehouse. The consistency was lacking.

Within those set ups, the morale of the staff was also totally different and the pressure was maybe the same as in the other OpCo I described, but from a perception point of view of the staff, the people felt much more under pressure.

Looking at the structure of the organization, you mentioned how you had a role that, for EMEA, looked over logistics and transportation. How is Danaher structured between the different divisions they have, such as life sciences, diagnostics and so on?

This is constantly moving, but in the days when I was there, they had five different platforms. Each platform was pretty independent. There was life science, cancer diagnostics, the dental platform – I think that has already been sold – and the water platform. Everybody is pretty independent in the platform, but there are plenty of synergies and enabling functions. This is where they really collaborated strongly.

That meant that when it came to procurement, we really leveraged our complete power, across platform and across OpCo. When it came to IT, we had different IT systems in place but, nevertheless, we also used the leverages. When it came to transportation and logistics, we really leveraged our complete entities and OpCos, for buying power with the freight forwarding companies. This worked pretty well.

Certainly, within the platform, you had much stronger collaboration. There were people with a market approach and, sometimes, you marketed with different companies, but each company offered a different segment of the process. The DBS was cross-platform, so the DBS guys and the trainers for the DBS, especially for the problem-solving process, they also acted in various platforms and across various OpCos. This was also very good because you changed your know-how and you brought in different perspectives and views from other sides, from other countries, from other market requirements and so on, so you could really leverage these things.

For Leica, for example, they operate within the diagnostics vertical. Were they using their own logistics network or were they actually combining with another group and outsourcing to freight forwarders?

Yes, Leica was like that. For all of the companies, we had some preferred forwarders and every company, such as Leica, managed their preferred forwarders. Danaher had some quotations and pricings and general guiding rules, then it was operated by the local OpCos. Each OpCo always needed to go and find good solutions for themselves, also from a costing perspective, to improve performance and competitiveness.

Most of the things were done by third parties, such as 3PL logistics. We also had some of our own warehouses, but the clear trend was to go for outsourced situations, where they really had the experts.

So you would use the scale between Leica, Beckman or Radiometer and put all that volume through the forwarders?

Exactly; we did it like that. We also had some common approaches like consolidated streams from China, where multiple OpCos joined forces. We had a train approach, with complete containers every week. This was inspired in the committee, for all OpCos, but then it was up to each logistics manager of the different divisions or different parts of the complete Danaher company, to choose whether they cooperate or collaborate or not and what made the most sense for them.

But there were certainly clear rules and guidance in place. You could also do something different, but only in the cases where you had very good arguments from a performance or costing perspective.

You used to run logistics for Leica, so there was a head of logistics for each area? For Leica, for Beckman, for Radiometer?

Did they report into a head of diagnostic logistics.

They normally reported to the Vice President or President of their own OpCo. In my case, in Leica. But at the same time, we had one guy, on the platform, taking care of all logistics topics across Europe and one guy taking care of all logistics topics across the globe. The same also applied for procurement, finance and so on. You always had the connection to the platform.

That was your role, to drive synergies between the other OpCos in the platform?

Exactly. For example, the European guy for logistics had a committee of four or five different people and, together with him, we then looked for synergies across the different OpCos. For example, we could see that are multiple production sites in China, and they all have to deliver something into Europe. What are the locations? Maybe it would be a good approach to combine these forces on a consolidated model, having a streamed approach to Europe, for example. Or maybe we have some kind of requirement for parcels, so now let’s do a parcel tender together. When it came to the issue of Brexit, some years ago, we also thought about how we could do it, because multiple Danaher companies were sitting in the UK, we had multiple warehouses in the UK and so on. We wondered how we could deal with the Brexit scenario and then we organized a summit, twice a year, where best practices were shared. Additionally, we had some global guidelines and some global rules, where we could support these people.

How do you look at the opportunities, going forward, to drive more scale and cost savings in distribution and logistics for the business?

I think it has multiple layers. From a pure freight perspective, as the company is growing and growing and growing, you certainly spend volume increase. As we have found out, opportunities to sell to customers increases in these good conditions. When I was there, it was always pretty clear that every OpCo, every year, in transport and logistics, there was a mandatory 5%.

The next issue, that has been discussed multiple times, is that normally, when you look at the footprint of all the Danaher companies, you might see that you have redundancies in warehouses or distribution centers, for example. In my opinion, there is still a lot of potential there, for consolidation. I only had this in Leica and, for example, I consolidated only seven warehouses in EMEA.

You consolidated the product and then put it through a freight forwarder or you shut them down and merged them into one larger facility?

We moved it to a larger facility. We needed to perform a center of gravity analysis, for example, and also increase the capabilities of that kind of center. Then we merged them.

From different OpCos?

No; we only did it for Leica.

So you had a hard 5% per year, decrease in the total opex for Leica, every year, no matter what?

It was more than 5%. I did this for EMEA, I had a counterpart in Asia and I had a counterpart in the US. We all did this. For example, only for EMEA, each year I had seven digits net cost reductions. Every single year.

That’s 5% of sales that you had to decrease opex by?

I cannot remember exactly how much it was, but it was really substantial. Within the matrix, I went for the matrix called OMEX, operating margin expansion, cash flow and the stock situation and I also went for delivery, which is on-time delivery. These were my three matrices that I needed to perform.

You had hard targets for each of those three?

As I said, normally the issue was that you just take the P&L from last year and you take 5% off. But you really want to be very sure. My approach, with my managers, was always to have a funnel of at least 7% to 9% and out of that, we made it happen. We always came in with 7% or 8%.

Is that the absolute target, though? Let’s say I’m doing a billion dollars in sales and I have 500 million in costs, if I take 5% of that, but my sales grow 10%, I’m going to have to do even less costs on a larger sales base?

This is a good question. When I was pretty new and Leica was clearly growing, I got my first budgeting and then it was communicated to me, Bruno, you need to cut down 5% of the costs. I said yes, but we grew, let’s assume 8%. My nice guy from the platform said, Bruno, what did you not understand? No matter what the growth is, you go down with the costs. We did it and I wasn’t sure whether he took it that seriously or not, but we had this as a stretch target and my task was pretty clear; I had to make it happen. We always did.

Where is the limit with Kaizen and continuous improvement? How much can you really take out in costs, before you start hurting the product?

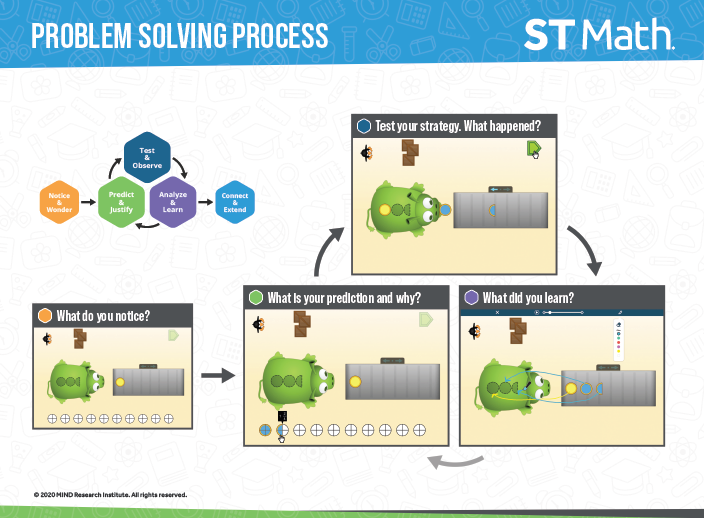

I don’t think there is really a limit. I will tell you why. One major part of the DBS culture is the so-called problem-solving process, the PSP. The PSP is run in two different ways. Across Danaher, they had about 200 PSP trainers for all facilities and all companies. I was also one of them. As I mentioned, you do it in two ways. You can have some cost problems or some creative problems. For example, a cost problem is when you were able to do something and, all of a sudden, you failed. Let’s say that you always had an on-time delivery of 95% and, all of a sudden, it drops to 92% or whatever. Then you need to find out why, what’s the story, what’s the root cause and fix it. This is one issue and this is normally the old Kaizen approach, as we see it in many industries.

The second one is a creative problem. For example, you say, today, I have logistics costs of €6 per pick line. Now my creative problem says, I want to go for cut by half approach. So my target to really cut this by half and get it to €3. Normally, when you reflect about it you would say, this is not possible. The assumption that they were doing that badly before is totally unrealistic. But when you are going for such a fantastic approach, you really need to think out of the box and then you find ways to do it.

I’ll give you an example. When I had my first meeting with one 3PL, I was in that situation. I told him, look, we really need the costs to go down by 5%, because everything must go down 5%. He looked at me and smiled and said, I am a 3PL, I am a contract logistics company. I don’t have 5% profitability. My profitability is about 4% to 5% and if I give it all to you, I will make zero or even be negative, so this is not how it works. I told him that I understood that, but no matter what, we need to go for this. Now creativity is needed. What did I do? I said, I see your point and I also wanted to benefit from that approach, so we went for a gain share approach. This meant that we agreed on, for example, to have a common program, starting with a VSM workshop and then, later on, some checkpoints and some dynamic pricing. We took a deep look at the complete process, from both the Leica and the 3PL side and what we found, we shared 50:50, but these are the activities we drive together, to bring prices down and to bring costs down. We increased profitability on his side and on our side. We did this. The 3PL was astonished what we could do and also, our people were pretty impressed by what we could do because the 3PL was running on very low costs and had been benchmarked for several years, from a costing perspective and always seemed to be super, super low.

With this VSM, as I mentioned, we identified multiple cost drivers, meaning that we needed to change something on the Leica Biosystems side, but also some things on his side. In the end, we cut the price per line by more than half. It was not that complicated. In the second phase, the year after, we could not do the next 50% approach as it would not work, but we could go for further improvements, such as the next 5%.

How would you describe the essence of DBS?

The DBS is the DNA of the whole thing. It is about transparency, involvement and permanent improvement. It’s about really reflecting on positions, really reflecting what it is and then use methodology and the PDCA cycle to make things happen with action plans, but then really monitor this rigidly. It is very painful. In the beginning, I hated it, having to be monitored every single week. Have I done this, this, this and this? I said to someone, I’m grown up; I don’t need to do this. After some time, I realized that with that kind of rigid monitoring, you really gain traction. Normally, whatever happens, the first question is, do you want a PSP? The second question is, do you have an action plan? The third question is, have you executed the action plan? The last question is, is your action plan bringing the projected results? If you fail to say yes, yes, yes, yes, you always go one step back.

What is the most important point of that process?

I think the most important thing is to move away from perceptions and assumptions, and to really go on the Gemba and do some analytics on the Gemba, find out the root causes, not as a sole activity, but as a team approach; not blaming anyone but really going to find out the problem. Then make it happen.

How do you make it happen?

You need to identify potential counter measures. You need to test them on a small scale and, if they work on a small scale, you take it to a larger scale. How do you do this? You have an action plan; you do the monitoring every single week and stick very closely to your plan. The action plan should normally tell you about the gap and which delta you will close with which action. You make the calculation or the pulse check, in reality, as to whether it flies or not.

How does the PSP work?

Before you can do things like that, you need to take a training course. You have a DIVE model where you learn, for example, how to define a problem, how to verify the situation, how to investigate the root causes. Then, later on, how you go for sustainability. It starts with how to state the problem; most people fail to really articulate a problem. For example, what I hear pretty often is, why are my goods entries too slow? What does too slow mean? Do I mean two days or five days? The next question would be, what is the standard? How fast should it be? The next question is, is this a one-time observation or is this a trend? You see this with multiple companies that they act like that, so they really are very busy, but they waste their resources like this. Normally, everything will start with the definition of a problem, so you really need to be clear how you define a problem. Therefore, you have to have tags. This means that you have to have a clear goal or target, you need to have data and you need to have a trend so you can see if this is a one-time wonder that you need to trace, or is it something that is moving in a certain direction?

The next issue is that you should be very clear about the rationale. Why should we work on this problem and not on another one? Therefore, you should be clear about the consequences of what happens if you just do nothing. Now you have the definition.

When you have done the definition, the next thing is that you need to be clear about who can help you to solve this. Therefore, you do the investigation. The investigation can be done with multiple analytic activities. For example, you can perform diagram or you go for the BOB or the WOW! approach or the visual map; there are lots of different methods to use. In the end, you will find out, during the investigation, some kind of priority principle situation. This means that only if things are related do they have an impact. From that, you derive the priority one, which gives you the overview and then you try to slice and dice a little bit, so that you can get to more details. The priority one normally deals with the what, and the priority two normally deals with where does it appear.

From that, you get some pretty good information as to where to dive deeper to get to the root causes. Then you need to work with more people, with multiple people, the experts and then really go to Gemba and observe it yourself, with the team and go for the 5 Whys approach and the root causes.

From the root causes, you can work out some counter measures. When you are looking at the counter measures, you normally have two types. You have permanent ones, for example, you find something and you can change it to a permanent approach. Or you have some counter measures that are only temporary, a bit like the fire brigade. For example, you install a 100% quality inspection, unless you really know about the specific issue and how to fix the specific issue for the root cause and have it sustainable.

Now you have done the investigation and looked at the counter measures. Then you go to verify your counter measures. Is this what you really meant, also bringing in the relevant results to close the delta. You need to verify this, so you have to test it out and do try-storming or, in the US, I think they say use bullets and then cannonballs, so you do something like empirical creativity, you try it out to see if it’s good. Then when you have done this, you go for sustainability. In the beginning, you put this in the daily management to really see whether it stays in the new preferred situation. If it does, after some time, you fade it out of the daily management, because it’s fixed. This is normally how the problem-solving process works.

You mentioned that Danaher has 200 PSP trainers?

Exactly. You can’t say, I want to be a PSP trainer. You need a recommendation from a vice president to be educated in this. Then you run through various training courses. Then you also have to prove that you have run various PSP activities successfully, by yourself, sustainably. After that, you can coach a PSP class and then you are a PSP trainer and you can teach PSP classes, PSP courses, across the globe, across all the different OpCos.

It seems really strict.

It is. For example, during the board meetings, in a lot of OpCos, there is no PowerPoint. At that level, they also work with the PSP approach. They will look at what the problem is, these are the tags, so this is why we are doing it; this is the rationale, this is the priority and these are the action plans. It is very rigid and strict. It’s almost like a language, I would say. But it’s also very good because PSP is about facts and figures; numbers talk. In PowerPoint, you can have a lot of fancy and so you can influence people beyond facts and figures. Danaher is pretty keen on facts and figures only.

Why is the PSP process so difficult to copy?

I think the PSP process is difficult to copy because we all have some kind of bad habits. Particularly, the higher you are in the hierarchy, the more bad habits you might have and you forget to listen. It seems that, sometimes, we like to jump to conclusions, without having really understood the question. That is a problem. There is also an issue with lack of discipline. You cannot say, today I will do a PSP and tomorrow I will have the right answer. No, it doesn’t work like that. The result will not appear immediately, but it will appear and then you have it sustainably. This is where a lot of companies fail.

It also seems as if most companies wouldn’t want a culture that was as strict and rigid as that, potentially?

You are right. I can honestly tell you, in my current company, I have now also introduced PSP because I really strongly believe that it creates maximum traction. I think any kind of fundamentalism is not so good. Nevertheless, you can always go for the Chinese approach saying, what is really good, you take it and you adopt it to your specific situation. It’s a very good tool. I also train my people now, here in my new company, and have told them pretty clearly that we want to follow a PSP approach and certainly, all of a sudden, they see a lot of benefits. Does it yet have the 100% traction? No, because I am not that rigid. But it’s much better than without it.

I think this is also where people should go for this. In various automotive companies, they copied it because it’s not Danaher specific. I think the Danaher people adopted it from the Toyota people. It’s good to know the methodology, but you really also have to apply it.

Is culture the biggest barrier to fully adopting a DBS-like system?

Yes; and then it’s about the leadership. When the leadership team clearly says, look, in my board meetings, there are no PowerPoints, I only want to stick to numbers, that’s a clear message. If you want to present a topic in the board meeting, you stick to the rules or you don’t do it.

What has been the biggest challenge for you, adopting principles from Danaher at your new company?

I would say, here in Germany, the culture is different. It is different in the way that people feel like grown ups here; people feel pretty experienced and educated. If you say to them, thank you very much; what you have done in the past is pretty good, but today we are going to do something very different and you must, more or less, forget everything, this is not so easy. They said, okay, yes, we now have to apply a new tool, but the PSP, it’s a mindset. To bring in the real traction, you also have to live according to it. Don’t go for perceptions; don’t go for assumptions. Just stick to the numbers. We don’t blame anyone; we learn together and improve together. But we try to avoid the same mistakes a second time.

You allow a culture of making mistakes, but only once. People need to get used to that kind of mindset. I know in many companies we send emails to each other, copied to multiple people so everyone, theoretically, knows but no one acts. No; for me in my new company, I said no. You don’t copy people in on emails, except when necessary. You don’t do it as standard, but as an exception.

Did Danaher use email cc function?

Yes; they also used email but in a way where people took responsibility. This depends on the leadership. For me, numbers talk and I really don’t care about the fact that you informed him or her. You either bring the numbers or you don’t bring the numbers. If you can’t bring the numbers, what can we do that will enable us to bring in the numbers? I always say, what is good is good, what is not good means that we name it not good or we name it bad and then, together, we think and reflect about what we can do to make it good. No excuses. The cc function is always abused and used as an excuse. I told him, so he should know. Bullshit; no.

Is it banned to cc in your company? Was it banned at Danaher, as well?

I would not say that it was banned, but it was not used too often.

How did the changes you made in the system drive a competitive advantage for Leica?

The advantage was in multiple areas. Firstly, the OMEX was growing, that was pretty clear. The second thing was that your capabilities grow. For example, I boosted the on-time delivery from around 90% to 98%, across EMEA and also I increased the capability of the major DC in Europe, in that you would be able to place an order by 4PM and, even if it was dangerous goods, the next morning, at 9AM, it would arrive in the hospital in London. When I started, this was not the case. The cut-off time was maybe midday, or something like that.

Are there any limitations to the type of company that you can apply the DBS system to?

I don’t really think so. I think you can apply it everywhere. You can also apply it in the service sector or in the intellectual property sector or creativity sector. Maybe creativity is a little bit difficult. We have also applied it in the creativity arena for innovations and stuff like that but I think, maybe, this is not the most powerful approach. Normally, the very creative people don’t like to stick to certain kinds of standards.

Also, you’ve got tangible and intangible assets. When you’ve got tangible assets, you can increase inventory turns or easily cut out opex, but how do you see this system being applied to intangible assets, such as software companies, for example?

I don’t think it’s so different because. With the PSP approach, for example, you have the standards and, sometimes, you are failing the standards, so you can have a problem. Or you might say, I might have a database search program and it takes this amount of time; now I want to cut that time by half, so you can also apply that methodology there.

Would all tools be applicable? I don’t think so. Also, in the tangible world, not all tools are applicable for everything. You really have to be clear. For example, a value stream map you can do everywhere, in my opinion, tangible or intangible. The same applies to PSP. 5S, for example, is a little bit different and it may depend on different variables. Things like SMED, for example, you can only do in the tangible world and not the intangible world. I think it depends on how you want to bring this type of culture in and how you want to live with it. I think daily management, in a software company for example, is absolutely mandatory. If you don’t have daily management, I think your traction will be close to zero. Daily management does not mean that I want to monitor other people but it means that we, every morning, we align on a certain status. Everyone is on the same chapter and the same page. Therefore, it is super mandatory to have things like that in place. Personally, I see no limitations.

Not in Danaher, but in another company, I once introduced a T-card system for process confirmation and this T-card system has been adopted by PricewaterhouseCoopers and they are not tangible company and they used it for their processes in their offices, obviously with different content, but the same methodology.

What could you do for sales and marketing efficiency, at a software company, for example, using DBS?

For sales and marketing, for example, you can run a PSP on the leads of a campaign and then try to find out why certain regions perform differently from other ones and then go with that methodology in that area. Out of that, you can identify some root causes and put some counter measures in place.

It’s just a mindset that can be applied to any business, but it does seem as if the real savings could be somewhat different when you have tangible assets versus intangible assets?

It’s hard to judge. We also did this, for example, for sales. In sales revenue, dollars are dollars. We saw that different regions were performing differently from other regions and, at first sight, it was not evident why this was the case. But when we dug deeper, we found that during the sales funnel build, there had been no standard work. As there was no standard work, in one region, they failed to build a proper sales funnel. From that insufficient sales funnel maturity, the related sales, later on, were too low in comparison to the targets. At first sight, you would not have recognized things like that because you would not have seen it. But with the PSP approach, we identified things like that. For sales, although there are things underneath it, but the pure number is pretty intangible.

What are the limitations to DBS?

It depends on how you really see DBS. Is it a box of methodology? Is it a mindset? For a mindset, I don’t think there are any limitations.

Maybe it’s the rigid culture that could be the downside, potentially?

A trade-off could be that, all of a sudden, you become fundamentalistic. If it’s too rigid, maybe you lose creativity. I think you need to balance it out a little bit. Try to take the benefits, try to really go for that approach, but not over-exaggerate it. I think this is why I think that they have such a high turnover rate in management staffing, but the Danaher folks, they sometimes over-exaggerate a little bit. But this also relates to leadership. Some OpCos have good turnover rates and some have not such good turnover rates and this is really dependent on the leadership. You cannot have a vice president team which consists of people where only one or two guys who have been there longer than two years; this doesn’t make sense.

How do they encourage that creativity at Danaher?

I cannot really tell you but I think that, at Danaher headquarters, they realized this issue, so they also put the turnover rate on the major matrix that seen by everybody. For example, when you, as a site or a company, have a turnover rate that is too high, you have to explain to your platform and the platform has to explain to the board. I can tell you, when you fail with these seven major indicators, you are in real trouble. Interestingly, they are related to the bonus of the management team, so they are always keen not to fail on one because the bonus is calculated on a multiplication. If something is very bad, it does not matter if the other elements of the equation are really positive.

When looking back, at your experience with DBS, what were the biggest lessons that you learned in applying that system?

One of the biggest lessons I’ve learned was how powerful the problem-solving process is. Previously, I would have thought it could be that strong. I’ve been aware of the methodology for a long time and I’ve been doing lean for at least 20 years now.

Doesn’t everyone do lean. There are the different methods, such as Six Sigma, so what is so different about DBS?

I think the real difference is that it’s about numbers. In the end, it’s about the relationship between the strategy and the policy deployment and the daily management. It’s pretty simple. There are only a very few indicators. You are not measuring tons of stuff with no impact. Then you are using the DBS to make it happen, to make it visual, to solve the problems, to identify the problems or to go for the crazy stuff in the future. I think this is the difference.

When it comes to Six Sigma, they only go for the cleaning out of the process variation. It’s a good approach but, therefore, you need to be very mature, upfront. This is why, in my opinion, most of the companies fail. To really be successful in Six Sigma, it takes a hell of a lot of discipline. That’s why I’ve seen it fail in most companies. It took them four or five years and, after four or five years, the board of directors says, okay, here are the results and the results were pretty limited.

It’s that PSP start at the beginning that seems to be unique to Danaher?

Yes, exactly. PSP is one of the major elements in the DBS tool box; this is the key. I normally tell my people, to be successful, you only need to know three things. One, you must be familiar with PSP. Two, you must have situational leadership. Three, you need to know about the theory of constraints. With these things together you have, I would say, 85% and the rest is about experience and luck. That’s it.

What do you think are the biggest limitations to Danaher growing into other sectors?

Growth in Danaher is complicated. I think they have a cash flow machine and, as long as that works, they can find the growth. What Danaher is doing, from a growth perspective, certainly the different OpCos grow organically, but also predominantly, by acquisitions. To finance acquisitions, you need a lot of cash flow and the cash flow you generate by the high OMEX and high margins, on one hand and the permanent cost reductions on the other hand. Also, from time to time, they sell some divisions on the stock market.

Do you think they could move into software or some of these higher, intangible asset-based businesses?

I think they can. I cannot speak for Danaher as a whole, but I can tell you, in the Leica Biosystems company, we were already in this field, as we had cancer diagnostics. We had one company with AI, algorithms, to identify and give the oncologist the hint as to where to look. From a legal perspective, we were not allowed to make a complete AI diagnosis, but the AI algorithms and the imaging related to it gave the oncologists a hint as to what could be the issue or where he should look.

And you were still applying DBS in that type of business?

Yes. It was the same situation, standard work, daily management and PSP.

How would you advise other companies, industrial businesses, to apply DBS?

I would say that the leadership team must be clear about what they want. Then go with the basics. We need to know, therefore, how every kind of organization is working. But you need to know that you have some kind of discipline impact, a reliability impact and a methodology impact. These are the base of any organization. On top of that, you then have the creativity and the self-motivation and the passion.

Most people and most companies forget that these things that I mentioned earlier are the base. If you fail with the base, you cannot make it to the top. Even Google is doing it the way I explained. Every kind of organization, from a social point of view, works like this. For a DBS approach or a lean approach, you first need to go for involvement of the people and then daily management; make things visible. Then train the people about the different types of ways of doing things. This is the next step; make things meaningful. Then you can go with the methodology of the PSP and all the other stuff. But you need to have the daily management first. It must be driven from the CEO or from the board of directors, otherwise it’s just a Mickey Mouse approach, like a lot of other things.

It must also be tied, pretty clearly, to the involvement of the people. Most companies, in my opinion, will fail if they hire one or two guys and they really think that these two guys can fix it. This is a total misperception. They can be the inspirators; they can be the people bringing in the methodology, but they need to inspire the people. My good advice would always be to measure something like the total maturity of a group. How many people, of your total population, took part in a Kaizen event or in lean training activity, within the last six months? Otherwise you only have five people who are interested in this topic. DBS or lean is about empowerment and also commitment from the people. But if only the so-called experts are doing the improvements, the other staff can just lay back and say, okay, just wait as the experts are coming in; they hopefully know what is good or not and they will fix it. But this is not how it works and it is clear that the results will not work out, in the end.

Bruno, if you were to analyze a company from the outside, looking in, how would you look to analyze companies to really understand how good they are, operationally, similar to Danaher?

It depends on the kind of industry and the kind of company. What I would do, initially, is to have a Gemba Walk, either through the offices, when it’s a software company or something like that, or through the shop floor for the logistics area. When you just walk through, you can see, immediately, what is going on or what is not going on. You can easily see things where they have some daily management in place, where they have tons of matrices on the wall and a lot of fancy graphics but, in the end, in my opinion, this is showtime. It makes zero sense and gives zero traction.

You can easily see if it’s meaningful, if it’s updated, do the people stick to what they do or is it just showtime? This is pretty easy. Then you can also see how people move. Not that they are in a hurry or running, but just about when you enter a fabrication, for example, is anybody trying to hide? I’m not here; please don’t ask me something, I might give you a bad answer. But if you come in and everybody is friendly and proud of what they are doing, even if it’s only putting four screws in a plastic molded part, you can see this immediately, in my opinion.

What other companies, apart from Danaher, are great at this type of operational efficiency?

I think the Toyota guys are great in that kind of methodology. Honestly, I’ve seen a lot of companies thinking they were great but not being really great.

Who is the best, apart from Danaher, in your opinion?

Maybe Toyota.

Related Content

Danaher Business System: Hach Sales Team Case Study

Former vp at danaher, danaher, beckman coulter, & the dbs machine, former laboratory automation sales manager, beckman coulter, danaher, danaher: implementing dbs in the sales process, former president at danaher, top 10 interviews in 2021, danaher, and in practise in 2022, copyright notice.

This document may not be reproduced, distributed, or transmitted in any form or by any means including resale of any part, unauthorised distribution to a third party or other electronic methods, without the prior written permission of IP 1 Ltd.

IP 1 Ltd, trading as In Practise (herein referred to as "IP") is a company registered in England and Wales and is not a registered investment advisor or broker-dealer, and is not licensed nor qualified to provide investment advice.

In Practise reserves all copyright, intellectual and other property rights in the Content. The information published in this transcript (“Content”) is for information purposes only and should not be used as the sole basis for making any investment decision. Information provided by IP is to be used as an educational tool and nothing in this Content shall be construed as an offer, recommendation or solicitation regarding any financial product, service or management of investments or securities. The views of the executive expressed in the Content are those of the expert and they are not endorsed by, nor do they represent the opinion of In Practise. In Practise makes no representations and accepts no liability for the Content or for any errors, omissions, or inaccuracies will in no way be held liable for any potential or actual violations of laws, including without limitation any securities laws, based on Information sent to you by In Practise.

© 2024 IP 1 Ltd. All rights reserved.

Creations Engineered

Implementing the Problem-Solving Process (PSP) in the Engineering Environment

Leveraging the why-why-why technique.

In today’s fast-paced and competitive engineering environment, quick and effective problem-solving is essential to maintaining operational excellence, driving innovation and capturing market share. The Problem-Solving Process (PSP) provides a structured approach to addressing complex engineering problems , from identifying and defining problems to selecting, implementing and verifying solutions. By utilizing the Why-Why-Why Technique, engineers can dig deeper into issues to uncover the root causes, leading to more robust and sustainable solutions. This method improves the problem-solving capabilities of engineering teams, ensuring that challenges are addressed comprehensively and systematically, resulting in successful outcomes for various engineering projects . “Fix it Once, Fix it Right!”

Let’s look at it with a simple case study.

Step 1: Identify and Define the Engineering Problem

Let’s assume we have designed a new electronic device enclosure. During testing, it was found that the device overheats, causing performance degradation and potential damage to internal components.

Problem Definition: The specifications require the device to operate within a temperature range of 0°C to 50°C, but it overheats, currently reaching temperatures of up to 70°C under normal operation

Step 2: Analyze Possible Failure Modes in the Engineering System

Failure Modes Analysis: Engineers analyzed the enclosure design and identified several contributing root causes that gave rise to the overheating issue :

- The power consumption of internal components generates heat.

- Inadequate enclosure ventilation leads to poor heat dissipation.

- Heat sink orientations and locations are not optimum for cooling.

- Poor thermal conductivity materials are used in the enclosure.

Using the Why-Why-Whys Technique,

Continue to ask why until you reach the root cause, don’t be fooled by symptoms.

Why is the device overheating? Because the internal temperature exceeds the safe operating range.

Why does the internal temperature exceed the safe range? Because the heat generated internally is not dissipating efficiently.

Why is heat not dissipating efficiently? Because the enclosure lacks adequate ventilation.

Why does the enclosure lack adequate ventilation? Because the design did not include sufficient vents or cooling mechanisms.

Why did the design not include sufficient cooling mechanisms? Because the initial design focused more on aesthetics, noise levels and compactness rather than thermal management.

Step 3: Generate and Analyze Potential Solutions through Creative Thinking Potential Solutions:

- Use additional heat sinks and thermal conductive materials to enhance heat transfer and dissipation.

- Orient the finned heat sinks to take advantage of natural convection.

- Redesign the enclosure to include additional vents for convective cooling, for both cool air in and heated air out.

- Add an active cooling system (e.g., small fans) to supplement natural convective cooling.

- Optimize the power consumption of internal components to reduce heat generation.

- And, if necessary, incorporate phase change materials, taking advantage of the thermal duty cycle and PCM’s ability to absorb, store and release heat over time.

Step 4: Solution Set Critical Parameters Optimization and Verification Testing:

Analysis led the engineering team to redesign the enclosure to include additional vents and integrate a small, efficient fan for active cooling. They oriented the finned heat sinks to take optimum advantage of both the natural and forced air flow within the enclosure. They also replaced some internal materials with better thermal conductors.

Sequential Validation:

Bench Fixture Testing: The new enclosure design was tested in a controlled worst case environment to measure temperature changes and ensure the cooling system functions correctly.

Sub-System Testing: The enclosure was tested as part of a larger assembly to ensure it interacts well with other components.

Full System Testing: The complete device, with the new enclosure, was tested in real-world conditions to verify overall performance.

These tests showed a significant reduction in the operating temperatures, keeping the device well within the safe range of 0°C to 50°C.

Step 5: Implementation of Changes and Manufacturing Try Out:

Once all of the enclosure changes were successfully validated, tooling was modified, assembly fixtures updated and the new enclosure assembly was tried out in the production environment. The production team was trained on the new assembly procedures and quality control processes were updated to ensure consistent implementation of the new design.

Step 6: The Change is Cut-In, introduced into the Field and the Performance is Monitored:

Field performance is continually monitored to confirm that the Problem is Resolved .

In Summary:

By following the Problem-Solving Process (PSP) and leveraging the Why-Why-Why technique, we effectively identified the root cause of the overheating issue and implemented a sustainable solution. This structured approach ensured that the problem was comprehensively addressed and quickly resolved, leading to the improved performance and reliability of the electronic device.

Henry T. Bober

Subject Matter Expert, Srushty Global Solutions

A seasoned expert in Mechanical Design Engineering with 40 years of experience at Xerox Corporation, where he specialized in Product Development and Integration, Cost-Effective Design, Project Management, Technology Development, and Product Architecture. Holding a Bachelor’s degree from West Virginia University and a Master’s degree from the University of Rochester, Henry has been instrumental in Media Handling and Feeder Technology Development, amassing 30 US and 5 European patents. Post-retirement, he founded Fast Forward Engineering, consulting for industries such as copiers, ATMs, and medical devices, with clients including Xerox, Diebold, NCR, Siemens Medical Products, Abiomed, Sycamore Hill Designs, and Impossible Objects. Henry is currently a Subject Matter Expert at Srushty Global Solutions. Residing in Fairport, NY, with his wife Leslie and their numerous pets, he enjoys Western-style horse riding, Japanese garden landscaping, woodworking, studying naval warfare history, and advocating for animal welfare.

Keep Reading: Know More on Exploring the Unique Roles of Industrial Design Vs Product Design!

Comments are closed.

Breadcrumbs Section. Click here to navigate to respective pages.

The Problem-Solving Process Wheel

DOI link for The Problem-Solving Process Wheel

Click here to navigate to parent product.

This chapter focuses on the Problem-Solving Process (PSP) wheel. The PSP wheel breaks down managers problem-solving activities into eight defined areas, much like a map. The eight areas of the PSP wheel are: identify problem, gather data, analyse data, generate solutions, select solutions, plan, test and rehearse, and action. These eight areas provide reference points to manage their problem-solving journey. By using the PSP wheel to manage their problem-solving journey, managers can distance themselves from the emotion and chaos surrounding the actual problem, deliberately manage their attention through creative techniques to locate, define and solve the problem. The PSP wheel makes it possible for managers to manage their tactics with the background of a sound strategic model. One of the central themes behind the structure and content of the PSP wheel has been to combine simplicity with accessibility. The eight stages in the wheel fall into three sub-processes: foundation, generation and execution.

- Privacy Policy

- Terms & Conditions

- Cookie Policy

- Taylor & Francis Online

- Taylor & Francis Group

- Students/Researchers

- Librarians/Institutions

Connect with us

Registered in England & Wales No. 3099067 5 Howick Place | London | SW1P 1WG © 2024 Informa UK Limited

| Problem solving requires a disciplined approach that brings out the best of our past knowledge, the best of our creative talents and the best of our analytical tools. Here's one approach to consider for performing systematic problem solving: Step 1: Identify and Select the problem Step 2: Analyze the Problem Step 3: Generate Potential Solutions Step 4: Selecting & Planning the Solution Step 5: Implementing Solution Step 6: Evaluating Solution Note: Although the six steps of the Problem-Solving Process are numbered, people seldom proceed from Step 1 through Step 6 without revisiting and revising earlier steps.

|

- Standard Products

Problem Solving Process (PSP)

LIMITED OFFER!

10% Instant discount for the team member of six

Learn about the latest advances in TQM methods and its application

Register Now

WhatsApp us

We don't do goodbyes

We do see you later..

In case, if you want to chat with us we are one step away.

No, Thanks!

ENHANCING STUDENTS’ PROBLEM-SOLVING SKILLS THROUGH CONTEXT-BASED LEARNING

- Published: 28 August 2014

- Volume 13 , pages 1377–1401, ( 2015 )

Cite this article

- Kuang-Chao Yu 1 ,

- Szu-Chun Fan 1 &

- Kuen-Yi Lin 1

3113 Accesses

62 Citations

3 Altmetric

Explore all metrics

Problem solving is often challenging for students because they do not understand the problem-solving process (PSP). This study presents a three-stage, context-based, problem-solving, learning activity that involves watching detective films, constructing a context-simulation activity, and introducing a project design to enable students to construct a complete PSP. This study was conducted among 103 eighth-grade students over a period of 14 weeks. The descriptive statistics and structural equation model were used to analyze the students’ PSP performance. Results indicate that context simulation is beneficial for cultivating students’ abilities to establish and analyze questions and then select and develop solutions. In addition, the project design cultivated the students’ ability to evaluate results and apply feedback. Findings from this study demonstrate that context-based learning may effectively enable students to establish a complete PSP.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or Ebook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Social Learning Theory—Albert Bandura

The Gamification of Learning: a Meta-analysis

Virtual reality and gamification in education: a systematic review

Aduriz-Bravo, A., Izquierdo, M. & Estany, A. (2001). A characterization of practical proposals to teach the philosophy of science to prospective science teachers. In N. Valanides (Ed.), Science and technology education: Preparing future citizens (pp. 37–47). University of Cyprus: Paralimni.

Google Scholar

Ahmed, S., Wallace, K., Lucienne, T. & Blessing, L. (2003). Understanding the differences between how novice and experienced designers approach design tasks. Research in Engineering Design, 14 , 1–11.

Article Google Scholar

Arroio, A. (2010). Context based learning: A role for cinema in science education. Science Education International, 21 (3), 131–143.

Atman, C. J., Adams, R. S., Cardella, M. E., Turns, J., Mosborg, S. & Saleem, J. (2007). Engineering design processes: A comparison of students and expert practitioners. Journal of Engineering Education, 96 (4), 359–379.

Barak, M. & Mesika, P. (2007). Teaching methods for inventive problem-solving in junior high school. Thinking Skills and Creativity, 2 (1), 19–29.

Chin, W. W. & Todd, P. (1995). On the use, usefulness, and ease of use of structural equation modelling in MIS research: A note of caution. MIS Quarterly, 19 (2), 237–246.

Conley, D. (2011). Building on the common core. Educational Leadership, 68 (6), 16–20.

Crismond, D. P. & Adams, R. S. (2012). The informed design teaching and learning matrix. Journal of Engineering Education, 101 (4), 738–797.

Daugherty, M. (2001). Problem solving in appropriate technology. In R. C. Wicklein (Ed.), Appropriate technology for sustainable living: ITEA 50th yearbook (pp. 170–201). Reston, VA: International Technology Education Association.

Deek, F. P., Turoff, M. & McHugh, J. A. (1999). A common model for problem solving and program development. IEEE Transactions on Education, 42 (4), 331–336.

Dewey, J. (1910). How we think . Boston: D.C. Heath & Co.

Book Google Scholar

Dixon, R. A. & Brown, R. A. (2012). Transfer of learning: Connecting concepts during problem solving. Journal of Technology Education, 24 (1), 2–17.

Dubeck, L. W., Moshier, S. E. & Boss, J. E. (2004). Fantastic voyages: Learning science through science fiction films (2nd ed.). New York: Springer.

Efthimiou, C. & Llewellyn, R. A. (2004). Cinema as a tool for science literacy. Physics Education, 16 (1), 1–13.

Fechner, S. (2009). Effects of context oriented learning on student interest and achievement in chemistry education . Berlin: Logos Verlag.

Ge, X. & Land, S. M. (2003). Scaffolding students’ problem-solving processes in an ill-structured task using question prompts and peer interactions. Educational Technology Research and Development, 51 (1), 21–38.

Gick, M. L. (1986). Problem-solving strategies. Educational Psychologist, 21 , 99–120.

Hair, J. F., Anderson, R. E., Tatham, R. L. & Black, W. C. (1998). Multivariate data analysis . Englewood Cliffs, NJ: Prentice Hall.

Hennessy, S. & McCormick, R. (1994). The general problem-solving process in technology education: Myth or reality? In F. Banks (Ed.), Teaching technology (pp. 94–107). New York: Routledge.

Hennessy, S., McCormick, R. & Murphy, P. (1993). The myth of general problem-solving capability: Design and technology as an example. The Curriculum Journal, 4 (1), 73–89.

Hill, A. M. (1998). Problem solving in real-life context: An alternative for design in technology education. International Journal of Technology and Design Education, 8 (3), 203–220.

Hong, J. C., Hwang, M. Y. & Tai, K. H. (2012). Applying the BaGua to revitalize the creative problem solving process during a goal oriented contest. Thinking Skills and Creativity. Advance online publication . doi: 10.1016/j.tsc.2012.09.003 .

International Technology Education Association [ITEA]. (2000). Standards for technological literacy: Content for the study of technology . Reston, VA: Author.

Johnson, S. D., Dixon, R., Daugherty, J. & Lawanto, O. (2011). General versus specific intellectual competencies: The question of learning transfer. In M. Barak & M. Hacker (Eds.), Fostering human development through engineering and technology education (pp. 55–74). Rotterdam, Netherlands: Sense Publishers.

Chapter Google Scholar

Kadash, C. (2012, November). Context based simulation in nursing education: a student-centered experience towards pedagogical reform . Paper presented at the 5th International Conference of Education, Research and Innovation. Madrid, Spain: IATED.

Kelley, T. & Kellam, N. (2009). A theoretical framework to guide the re-engineering of technology education. Journal of Technology Education, 20 (2), 37–49.

Kirschner, F., Paas, F., Kirschner, P. A. & Janssen, J. (2011). Differential effects of problem-solving demands on individual and collaborative learning outcomes. Learning and Instruction, 21 (4), 587–599.

Labianca, D. A. & Reeves, W. J. (1981). Chemistry and detective fiction: An interdisciplinary program for the non-science major. Journal of Chemical Education, 58 (9), 683–686.

Lave, J. (1988). Cognition in practice: Mind, mathematics, and culture in everyday life . Cambridge, UK: Cambridge University Press.

Lave, J. & Wenger, E. (1991). Situated learning legitimate peripheral participation . New York, NY: Cambridge University Press.

Lochhead, J. & Zietsman, A. (2001). What is problem solving? In A. L. Costa (Ed.), Developing minds: A resource book for teaching thinking (3rd ed., pp. 54–57). Alexandria, VA: Association for Supervision and Curriculum Development.

MacKeracher, D. (2004). Making sense of adult learning . Toronto: University of Toronto Press.

Martinez, M. E. (1998). What is problem solving? The Phi Delta Kappan, 79 (8), 605–609.

McCormick, R. (1996). Instructional methodology. In P. J. Williams & A. P. Williams (Eds.), Technology education for teachers (pp. 63–92). Melbourne: Macmillan.

McCormick, R. (1997). Conceptual and procedural knowledge. International Journal of Technology and Design Education, 7 (1–2), 141–159.

McCormick, R. (2004). Issues of learning and knowledge in technology education. International Journal of Technology and Design Education, 14 (1), 21–44.

McCormick, R., Murphy, P. & Hennessy, S. (1994). Problem-solving processes in technology education: A pilot study. International Journal of Technology and Design Education, 4 , 5–34.

McLellan, H. (Ed.). (1996). Situated learning perspectives . Englewood Cliffs, NJ: Educational Technology.

Michael, K. Y. (2001). The effect of a computer simulation activity versus a hands-on activity on product creativity in technology education. Journal of Technology Education, 13 (1), 31–43.

Mioduser, D. (1998). Framework for the study of cognitive and curricular issues of technological problem solving. International Journal of Technology and Design Education, 8 (2), 167–184.

Mioduser, D. & Kipperman, D. (2002). Evaluation/modification cycles in junior high students’ technological problem solving. International Journal of Technology and Design Education, 12 (2), 123–138.

Murphy, P. & McCormick, R. (1997). Problem solving in science and technology education. Research in Science Education, 27 (3), 461–481.

Parush, A., Hamm, H. & Shtub, A. (2002). Learning histories in simulation-based teaching: The effects on self-learning and transfer. Computers & Education, 39 (4), 319–332.

Pilot, A. & Bulte, A. M. W. (2006). Why do you “need to know”? Context-based education. International Journal of Science Education, 28 (9), 953–956.

Putter-Smits, L. G. A., Taconis, R. & Jochems, W. M. G. (2013). Mapping context-based learning environments: The construction of an instrument. Learning Environments Research, 16 (3), 437–462.

Rahayu, S., Chandrasegaran, A. L., Treagust, D., Kita, M. & Ibnu, S. (2011). Understanding acid–base concepts: Evaluating the efficacy of a senior high school student-centred instructional program in Indonesia. International Journal of Science and Mathematics Education, 9 (6), 1439–1458.

Rose, D. E. (2012). Context-based learning. In N. Seel (Ed.), Encyclopedia of the sciences of learning (pp. 799–802). New York: Springer US.

Shahat, M. A., Ohle, A., Treagust, D. F. & Fischer, H. E. (2013). Design, development and validation of a model of problem solving for Egyptian science classes. International Journal of Science and Mathematics Education, 11 (5), 1157–1181.

Sternberg, R. J. (2001). Teaching problem solving as a way of life. In A. L. Costa (Ed.), Developing minds: A resource book for teaching thinking (3rd ed., pp. 451–454). Alexandria, VA: Association for Supervision and Curriculum Development.

Sternberg, R. J. (2009). Cognitive psychology (5th ed.). Orlando, FL: Harcourt College Publishers.

Sutherland, L. (2002). Developing problem solving expertise: The impact of instruction in a question analysis strategy. Learning and Instruction, 12 (2), 155–187.

Terri, E. V. (2005). The effects of a technological problem solving activity on FIRST TM LEGO TM league participants’ problem solving style and performance . Unpublished doctoral dissertation, Virginia Polytechnic Institute and State University, Blacksburg, VA.

Trimmer, W., Laracy, K. & Love-Gray, M. (2009). Seeing the bigger picture through context-based learning . Retrieved from http://akoaotearoa.ac.nz/download/ng/file/group-3300/seeing-the-bigger-picture-through-context-based-learning.pdf .

Vermeer, H. J., Boekaerts, M. & Seegers, G. (2000). Motivational and gender differences: Sixth-grade students’ mathematical problem-solving behaviour. Journal of Educational Psychology, 92 (2), 308–315.

Voss, J. F. & Post, T. A. (1988). On the solving ill-structured problems. In M. T. H. Chi, R. Glaser & M. J. Farr (Eds.), The nature of expertise (pp. 261–285). Hillsdale, NJ: Lawrence Erlbaum.

Whitten, S. & Graesser, A. C. (2003). Comprehension of text in problem solving. In J. E. Davidson & R. J. Sternberg (Eds.), The psychology of problem solving (pp. 207–229). New York, NY: Cambridge University Press.

Williams, B., Spiers, J., Fisk, A., Richards, L., Gibson, B., Kabotoff, W. et al. (2012). The influence of an undergraduate problem/context based learning program on evolving professional nursing graduate practice. Nurse Education Today, 32 (4), 417–421.

Williams, P. (2008). Assessing context-based learning: Not only rigorous but also relevant. Assessment & Evaluation in Higher Education, 33 (4), 395–408.

Wright, P. (2001). School-based issues and appropriate technology. In R. C. Wicklein (Ed.), Appropriate technology for sustainable living: ITEA 50th yearbook (pp. 133–152). Reston, VA: International Technology Education Association.

Young, L. E. & Paterson, B. L. (2007). Teaching nursing developing a student-centered learning environment . New York: Lippincott Williams and Wilkins.

Yu, W. F., She, H. C. & Lee, Y. M. (2010). The effects of web-based/non-web-based problem-solving instruction and high/low achievement on students’ problem-solving ability and biology achievement. Innovations in Education and Teaching International, 47 (2), 187–199.

Download references

Author information

Authors and affiliations.

Department of Technology Application and Human Resource Development, National TaiwanNormal University, 162, Heping East Road Section 1, Taipei, Taiwan

Kuang-Chao Yu, Szu-Chun Fan & Kuen-Yi Lin

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Kuen-Yi Lin .

Rights and permissions

Reprints and permissions

About this article

Yu, KC., Fan, SC. & Lin, KY. ENHANCING STUDENTS’ PROBLEM-SOLVING SKILLS THROUGH CONTEXT-BASED LEARNING. Int J of Sci and Math Educ 13 , 1377–1401 (2015). https://doi.org/10.1007/s10763-014-9567-4

Download citation

Received : 27 April 2013

Accepted : 12 May 2014

Published : 28 August 2014

Issue Date : December 2015

DOI : https://doi.org/10.1007/s10763-014-9567-4

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- context-based learning

- problem-solving process

- science detective films

- technological knowledge

- Find a journal

- Publish with us

- Track your research

Practical Problem Solving Tools for Factory and Office

February 5, 2022

Many tools exist to address deviations and defects, but only a few are simple yet effective to address daily issues in manufacturing, development, administration.

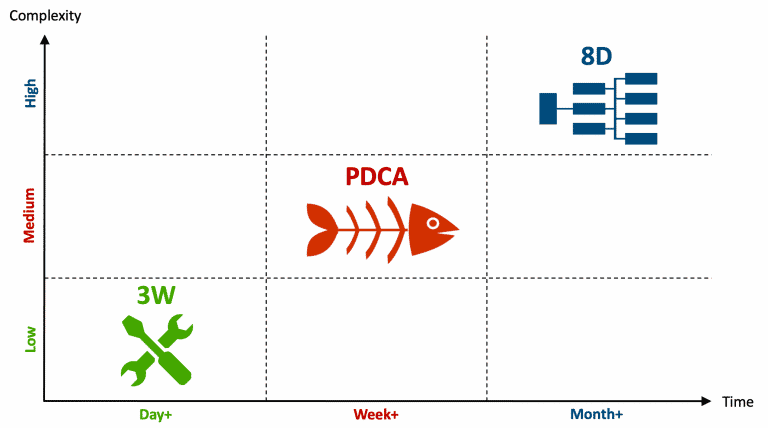

When starting systematic trouble-shooting, it is important to choose the right approach. Using a comprehensive method that requires 50 pages to solve a simple problem is a waste of time, while solving a complex problem with a simple tool will most likely not reveal the hidden causes. The optimal choice of Problem Solving Tools depends on the type of issues to be addressed. Before going into details, let’s first review the most common methods used today.

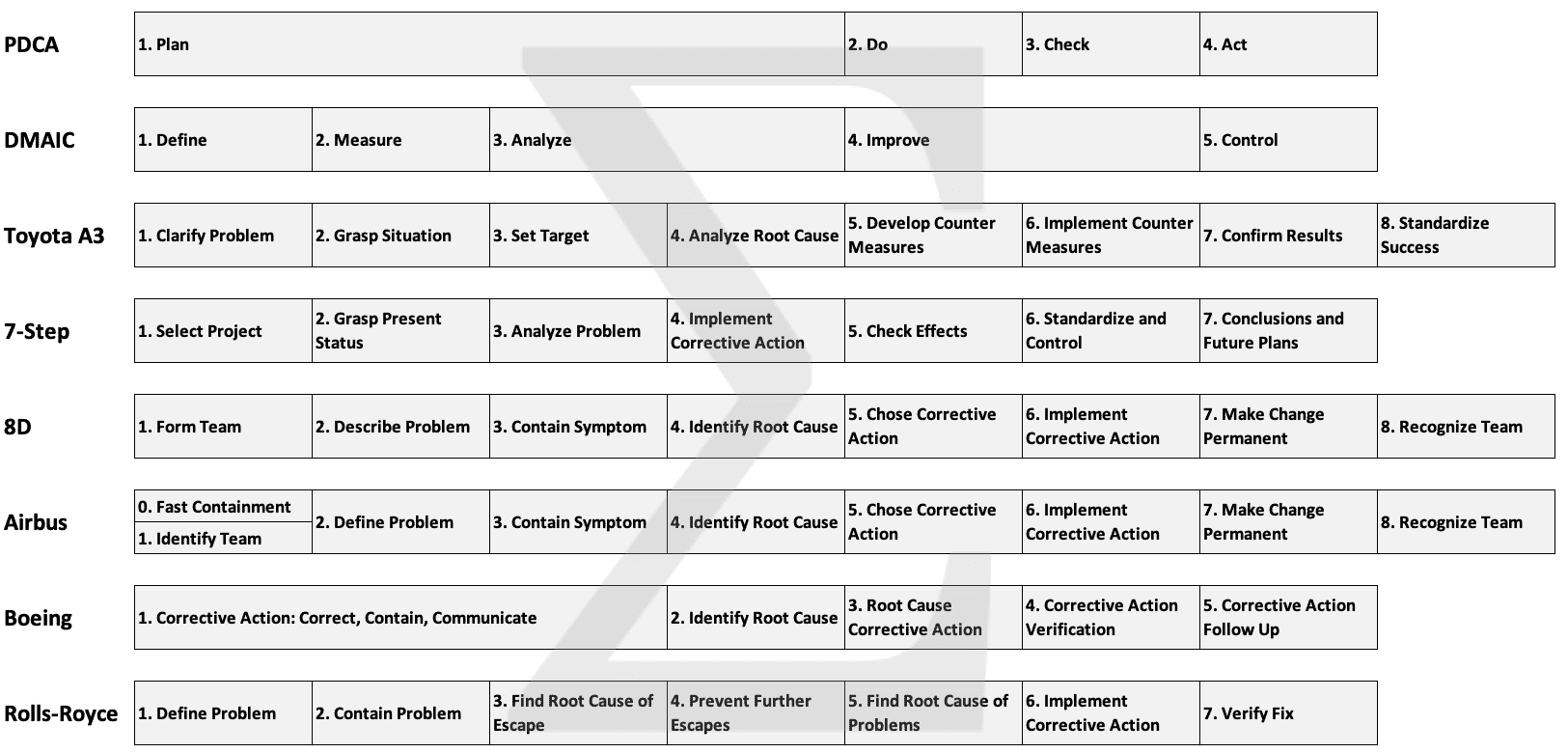

Comparing Popular Methods: 3W, PDCA, 8D, A3, DMAIC, 7STEP

At their core, all scientific approaches follow a similar logic: take quick action to prevent the problem from getting worse and then define the gap, analyze the gap, identify causes, take action, evaluate impact, and embed the solution so that the problem will not reoccur.

- 3W : When the issue is small and the solution is obvious, a formal analysis is not required. The 3W-method defines What to do, Who to do it, by When . This “quick-fix” or “just-do-it” is commonly applied at daily team meetings to contain and correct snags and minor issues.

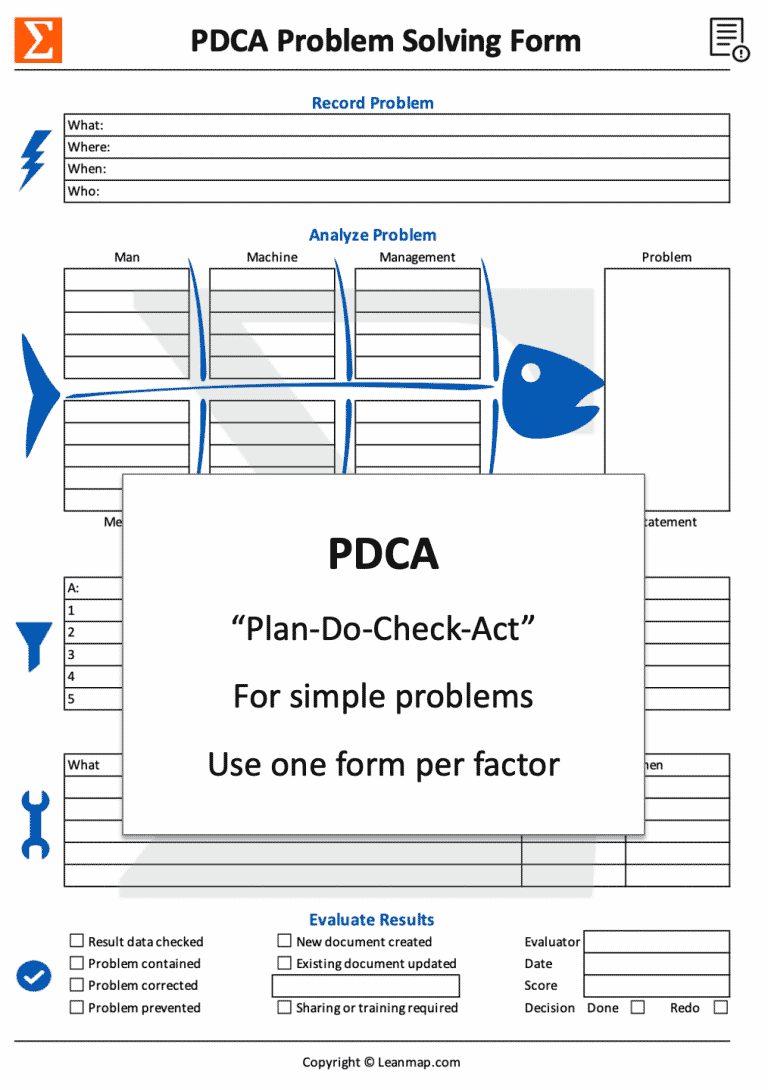

- PDCA : The Deming or Shewhart cycle “Plan-Do-Check-Act” is the classic method, used by over 80% companies that practice systematic problem solving. PDCA is effective for medium-size problems that require a systematic analysis to uncover underlying causes.

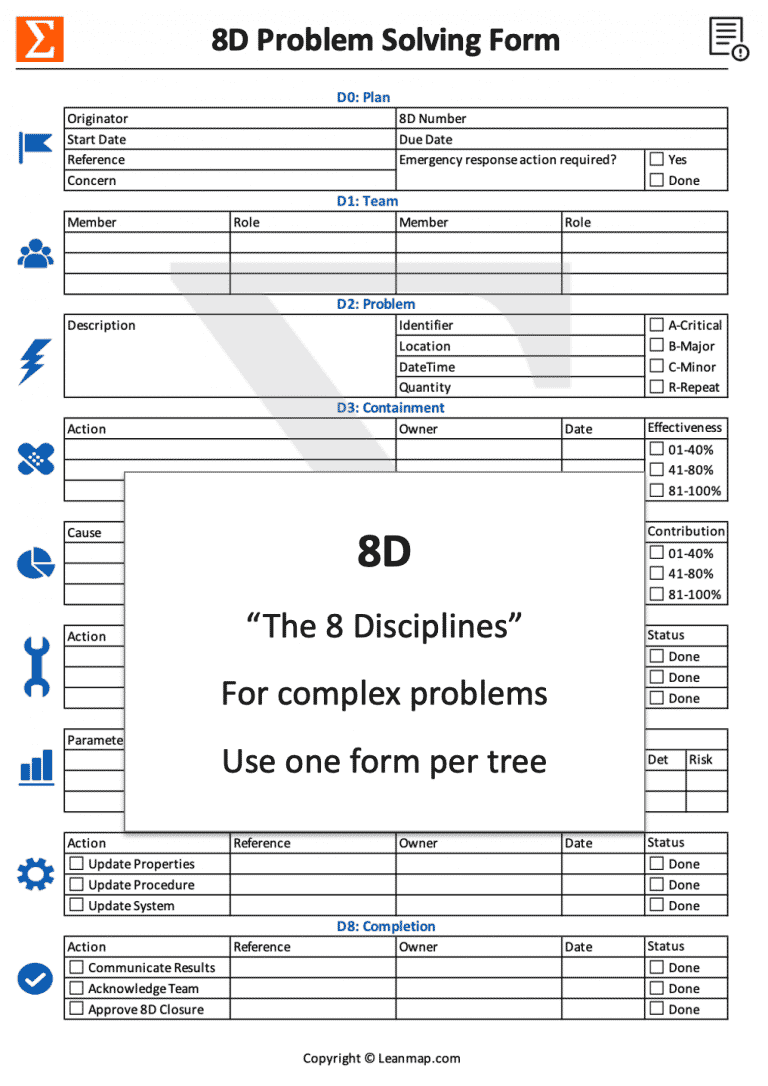

- 8D : The eight disciplines (8D) are commonly used in automotive, and the problem-solving process (PSP) in avionics. Both methods are similar, using 8 steps to address complex problems with focus on a fast reaction to non-conformances, completing the first three steps within three days.

- A3 : The A3-report, developed by Toyota, is an 8-step improvement and problem-solving process that fits on one sheet of paper. The A3-report is most effective to address small- to medium-size problems, and to structure improvement projects.

- DMAIC : The 5-step Six Sigma process “Define-Measure-Analyze-Improve-Control” is a data-centric solving method. DMAIC is used to structure projects and solve complex situations that require statistical analysis to develop the solution, e.g. adjust process parameters to reduce yield loss.

- 7STEP : This seven-step (7S) problem-solving process shares elements with the A3 and 8D, but does not include a formal step for containment. Because of this weakness, the 7STEP process is rarely used today, replaced by 8D to address major deviations and PDCA for smaller issues.

Comparing the most-popular processes for trouble-shooting and root-cause analysis shows how similar they are. For example, the PDCA planning phase covers the first three steps in DMAIC and the first five steps in A3 and 8D. Of all those processes, there are two that stick out, that all others are based on – PDCA and 8D – they are therefore considered the “mother” and “father” of practical problem solving tools used today.

Answer 5 Questions to Select the Best Method

When it comes to choosing the right process, it merely depends on the complexity of the situation to address. The more complex or severe, the more formal steps should be applied to make sure no step is missed. Here are five questions that will help you selecting the best process:

- Is the issue small, medium, or large?

- Is the solution obvious or unknown?

- Is it reoccurring or a single incident?

- Is it a single cause or multiple causes?

- Is statistical data analysis required?

3 Practical Problem Solving Tools: Fix, Fish, Tree

There are three practical, yet effective tools to address daily issues in factory and office: The 3W or “Fix” because it is quick, simple, informal;, the PDCA or “Fish” because it is based on the Ishikawa or Fishbone diagram;, and the 8D or “Tree” because it uses logical trees to analyze complex root causes.

- Fix: use 3W (What-Who-When) for informal trouble-shooting , finding a quick action to fix a small issue within a day .

- Fish: use PDCA (Plan-Do-Check-Act) to analyze simple and repeat issues within a week , using the fishbone diagram.

- Tree: use 8D (Eight Disciplines) to systematically eliminate multiple root-causes or complex problems within a month .

Tools and Templates to Eliminate Root Causes

To encourage people to go beyond containment and quick fixes, the method they use must be simple and practical, but also effective and efficient. Over the course of several years, we have tested dozens of different templates and found that the following two forms work best by far. Why? Because the user is given a clear structure, enhanced with pictograms, and the entire solving process can be completed on a single sheet, the key for broad adoption.

The PDCA and 8D templates have proven to be extremely effective in addressing non-conformances; they are practical problem solving tools for teams in manufacturing, quality control, product development, healthcare, back office, and corporate administration to successfully resolve daily issues and prevent them from coming back. You can download the free toolkit in 22 languages here .

Use PDCA Template to Solve Simple Problems

4 Steps to Eliminate Simple Causes

- Plan-1 Record Problem : Describe what happened, where and when, and who is involved solving it.

- Plan-2 Analyze Problem : Assign potential causes to categories: Man, Method, Machine, Material, Management, Milieu (Environment).

- Plan-3 Identify Causes : Ask “why” to drill down to root causes; for complex problems, use several forms, one per branch or issue.

- Do Implement Actions : Create and implement an action plan to contain, correct, and prevent the problem from reoccurring.

- Check Results and Act : Review impact, standardize solution; close the case or initiate further actions by starting a new PDCA cycle.

Use 8D Template to Solve Complex Problems

8 Steps to Eliminate Complex Causes

- D0 Plan : Register problem and define emergency response.

- D1 Team : Identify team members to address the problem.

- D2 Problem : Grasp the situation and describe the problem.

- D3 Containment : Prevent the problem from spreading.

- D4 Diagnostics : Identify direct causes and root causes.

- D5 Correction : Define and prioritize corrective actions.

- D6 Validation : Implement actions and evaluate effectiveness.

- D7 Prevention : Systemize solutions to prevent reoccurrence.

- D8 Completion : Transfer knowledge and recognize contributors.

Become an Effective Problem Solver by Applying Practical Tools and Learning Battle-Tested Methods

Effective Problem-Solving Techniques in Business