Table of Contents

What is lean methodology, the evolution of lean methodology, principles of lean methodology, 8 wastes of lean, benefits of lean methodology, challenges of lean methodology, agile and lean: similarities, agile and lean: differences, lean software integration, 4 lean process improvement examples, value stream mapping in lean manufacturing, what is lean methodology principles, integration, and examples.

For a business to be profitable, it must cut out waste and inefficiency, yet not all businesses fully adopt this approach. Lean methodology provides a solution, proposing a system through which businesses can reduce waste by fostering ongoing feedback cycles, review, and learning, thus enhancing efficiency and becoming "lean." This approach aims to deliver valuable, cost-effective, and competitively priced services, ensuring customer satisfaction.

Lean methodology is a systematic approach to continuous process improvement through the elimination of waste. It originated in the manufacturing industry, specifically within Toyota, in the mid-20th century as part of the Toyota Production System (TPS), which sought to maximize value for the customer through the optimal use of resources. The principles of Lean have since been adapted and applied across various sectors, including healthcare, software development , and service industries.

The evolution of Lean methodology can be seen as a series of adaptations from its origins in manufacturing to its application in diverse fields:

- Origins in Manufacturing: The roots of Lean can be traced back to the Toyota Production System, which was developed by key figures like Sakichi Toyoda, Kiichiro Toyoda, and Taiichi Ohno. The system emphasized efficiency, quality, and eliminating waste (muda), which included unnecessary steps, excess inventory, and defects.

- Spread to Other Industries: As the success of the TPS became evident, other industries began to take notice. By the late 20th century, Lean principles were adapted for use in other fields, including construction, healthcare, and IT. Each sector tailored the Lean principles to suit its unique challenges and processes.

- Lean Six Sigma: Integrating Lean methodology with Six Sigma practices, which focus on reducing process variation and improving quality, further evolved the approach. This combination, called Lean Six Sigma, aims to create more customer value by improving quality, speed, and cost.

- Digital Transformation and Agile: In software development and IT, Lean principles have merged with Agile methodologies to enhance flexibility, responsiveness to customer needs, and the rapid and efficient delivery of high-quality products.

- Continuous Innovation and Learning: Today, Lean methodology continues to evolve with a strong emphasis on continuous learning, innovation, and adaptation to the changing business landscape. It focuses on process improvements and fostering a culture of empowerment among employees, encouraging them to contribute to continuous improvement.

Lean methodology principles are fundamental guidelines that help organizations focus on value creation while minimizing waste. The five core principles of Lean methodology are designed to improve efficiency, quality, and customer satisfaction. They are:

- Define Value: The starting point of Lean is to specify value from the standpoint of the end customer. Understanding what the customer values in a product or service allows organizations to streamline their processes, ensuring that every action contributes towards fulfilling the customer's needs and expectations.

- Map the Value Stream: This principle involves identifying and mapping all the steps involved in delivering a product or service, from raw materials to the final delivery to the customer. The goal is to visualize the flow of materials and information throughout the organization. This mapping helps identify and eliminate non-value-adding activities (waste), ensuring that every step in the process adds value to the product or service.

- Create Flow: Once the value stream is identified, the next step is to ensure that the value-creating steps occur in a tight sequence, allowing the product or service to flow smoothly toward the customer without interruptions, delays, or bottlenecks. This can involve reconfiguring production steps, leveling workload, creating cross-functional teams, or adopting new technologies to enable a seamless flow of products and services.

- Establish Pull: Instead of pushing products through production based on forecasted demand, Lean dictates that production should be based on actual customer demand, thereby minimizing waste associated with overproduction and excess inventory. A pull-based system allows for a more responsive and flexible production scheduling and inventory management approach.

- Pursue Perfection: Lean is an ongoing process of continuous improvement. Pursuing perfection involves continually seeking ways to reduce waste and improve processes, thereby maximizing value for the customer. This principle encourages a culture of continuous learning and improvement, where employees at all levels identify inefficiencies and suggest improvements.

There are eight commonly recognized forms of waste in the Lean methodology:

- Defects: Errors or defects in products or services that require rework or correction, leading to waste through additional time, resources, and effort to fix the issues. This not only increases the cost of production but also delays the delivery to the customer.

- Overproduction: Producing more products than needed by the next process or the customer leads to excess inventory , tying up resources and space that could be used more productively.

- Waiting: Time during which work is not being done, or value is not being added, often due to bottlenecks, imbalances in workloads, or delays in processes. This can include waiting for materials, information, or equipment.

- Non-Utilized Talent: Underutilizing people’s skills, talents, and knowledge wastes potential and can lead to employee dissatisfaction. Engaging and empowering employees can lead to more innovative and efficient processes.

- Transportation: The unnecessary movement of products or materials between processes adds no value to the product but increases the risk of damage, delays, and costs.

- Inventory: Excess products and materials not being processed create storage challenges, tie up capital, and risk obsolescence or damage, leading to further waste.

- Motion: Unnecessary movements by people (e.g., reaching, walking, or bending) that do not add value to the product or service. Efficient workspace layout and ergonomic considerations can help reduce this form of waste .

- Extra-Processing: Doing more work or adding more features to a product than what is valued by the customer. This can stem from poor process design, unclear customer requirements, or over-engineering.

Boost your career path as a skilled quality management expert with our Lean Six Sigma Expert Training aligned with the LSS-Green Belt and Black Belt certification from IASSC. Contact us and get ahead in your career right away!

Lean methodology offers a comprehensive approach to operational excellence, emphasizing waste reduction, value creation, and continuous improvement. Adopting Lean principles can benefit organizations across industries, including manufacturing, healthcare, services, and software development. Here are some of the key benefits of implementing Lean methodology:

1. Increased Efficiency and Productivity

- Reduced Waste: Lean helps organizations streamline their processes by identifying and eliminating non-value-added activities, thereby increasing efficiency.

- Improved Workflows: Lean principles like creating flow and establishing pull help optimize operations for smoother workflows and reduce bottlenecks.

2. Enhanced Quality

- Fewer Defects: Focusing on continuous improvement and root cause analysis leads to higher quality products and services by minimizing errors and defects.

- Customer-Centric Approach: Lean emphasizes understanding and meeting customer needs, which inherently leads to improvements in quality from the customer's perspective.

3. Reduced Costs

- Lower Inventory Levels: Implementing just-in-time production reduces inventory costs by avoiding overproduction and minimizing storage requirements.

- Operational Cost Savings: Efficiency gains and waste reduction significantly lower operational costs.

4. Faster Delivery Times

- Improved Flow: Organizations can achieve faster turnaround times by streamlining processes and removing bottlenecks.

- Pull-Based Systems: Lean's pull-based systems ensure that products and services are produced only as needed, reducing lead times and enhancing responsiveness to customer demand.

5. Better Customer Satisfaction

- Alignment with Customer Needs: By defining value from the customer's perspective, organizations can better meet customer expectations.

- Flexibility and Responsiveness: Lean organizations can quickly adapt to changes in customer demand, improving customer satisfaction.

6. Higher Employee Engagement and Morale

- Empowerment: Lean encourages employee involvement in problem-solving and process improvements, leading to higher engagement and job satisfaction.

- Skill Development: Continuous improvement initiatives often include training and development, which can enhance employee skills and versatility.

7. Enhanced Competitiveness

- Agility: Lean organizations can quickly adapt to market changes and customer needs, helping them stay competitive.

- Innovation: The continuous improvement culture fosters innovation by encouraging new ideas and approaches to work.

8. Sustainability

- Environmental Benefits: Waste reduction goes hand in hand with reduced resource consumption and lower environmental impact.

- Long-Term Viability: Lean focuses on efficiency, quality, and customer satisfaction, helping ensure the organization's long-term success and sustainability.

Here are some common challenges associated with Lean methodology:

- Cultural Resistance to Change

- Misunderstanding Lean Principles

- Lack of Commitment

- Training and Education

- Integration with Existing Processes

- Measuring Success

- Sustaining Improvements

Become a Quality Management Professional

- 10% Growth In Jobs Of Quality Managers Profiles By 2025

- 11% Revenue Growth For Organisations Improving Quality

Lean Six Sigma Expert

- IASSC® Lean Six Sigma Green Belt and Black Belt certification

- 13 Projects, 12 Simulation exams, 18 Case Studies & 114 PDUs

Certified Lean Six Sigma Green Belt

- 4 hands-on projects to perfect the skills learnt

- 4 simulation test papers for self-assessment

Here's what learners are saying regarding our programs:

Abdus Salam

Completing Simplilearn's Lean Six Sigma Expert Master’s Program empowered me to excel in new projects, enhancing my performance significantly. Consequently, my research position's average pay rate surged by 21%.

Xueting Liu

Mechanical engineer student at sargents pty. ltd. ,.

A great training and proper exercise with step-by-step guide! I'll give a rating of 10 out of 10 for this training.

Agile and Lean methodologies are often discussed in software development, project management , and organizational efficiency. While Agile originated in the software development field as a response to the limitations of traditional waterfall project management methodologies, Lean comes from the manufacturing sector, particularly the Toyota Production System.

Despite their different origins, Agile and Lean share several core principles and philosophies that complement each other. Here are some of the key similarities between Agile and Lean methodologies:

1. Customer Value Focus

Both methodologies prioritize delivering value to the customer. Lean emphasizes understanding and delivering what the customer values by defining value from the customer's perspective. Agile focuses on customer collaboration and responding to customer feedback to ensure the end product is valuable to the customer.

2. Emphasis on Flexibility and Responsiveness

Agile and Lean both advocate for adaptability and responsiveness to change. Agile methodologies like Scrum or Kanban encourage teams to adapt quickly to changing requirements and environments. Similarly, Lean promotes flexibility in production processes to respond efficiently to customer demand and reduce waste.

3. Continuous Improvement

Continuous improvement is both Agile and Lean’s core principle. Agile methodologies incorporate regular retrospectives and iterative development to improve the product, process, and team performance continually. Lean uses the concept of Kaizen, or continuous improvement, to systematically reduce waste and improve efficiency and quality.

4. Elimination of Waste

While Lean explicitly focuses on identifying and eliminating waste (or "Muda") in processes, Agile also seeks to reduce waste, albeit indirectly, by minimizing unnecessary documentation, reducing over-engineering, and avoiding tasks that do not contribute directly to customer value.

5. Empowerment of Teams

Both methodologies emphasize the importance of empowering teams. Lean encourages involving everyone in identifying inefficiencies and suggesting improvements, fostering a culture of empowerment. Agile methodologies prioritize self-organizing teams that can make decisions rapidly and collaboratively.

6. Incremental and Iterative Work

Agile and Lean advocate for breaking down work into smaller, manageable pieces. Agile does this through iterative development cycles (sprints), delivering small increments of the product regularly. Lean achieves this by ensuring work flows smoothly and efficiently, often utilizing pull systems like Kanban to manage work in progress and deliver value incrementally.

7. Emphasis on Quality

Quality is a key focus in both methodologies. Agile methodologies incorporate quality assurance practices throughout the development process, ensuring quality is built into the product. Lean similarly emphasizes the importance of quality, aiming to do things right the first time to avoid waste associated with defects and rework.

8. Use of Visual Management Tools

Both Agile and Lean use visual tools to manage work and process flow. For example, Kanban boards are used in Agile and Lean to visualize work in progress, streamline workflow, and identify bottlenecks.

Agile and Lean methodologies share common principles but also have distinct differences, especially in their areas of focus and application contexts. Below is a table summarizing some of the key differences between Agile and Lean methodologies:

|

|

|

|

| Origin | Originated in software development as a response to project management methodologies limitations. | Originated from the manufacturing sector, particularly the Toyota Production System. |

| Primary Focus | Focuses primarily on improving the process of software development and project management. | Focuses on the entire value stream: manufacturing, supply chain, and operational processes. |

| Core Emphasis | Emphasizes adaptability, customer collaboration, and the ability to respond to change rapidly. | Emphasizes the elimination of waste (Muda), efficiency, and continuous flow in processes. |

| Key Principles | Defined by the Agile Manifesto, which includes customer collaboration, responding to change, and valuing individuals and interactions. | Based on principles such as defining value, mapping the value stream, creating flow, establishing pull, and seeking perfection. |

| Methodologies | Includes specific methodologies like Scrum, Kanban (shared with Lean), Extreme Programming (XP), and others. | While Lean principles can be applied broadly, tools like Value Stream Mapping, 5S, Kaizen, and Kanban (also used in Agile) are common. |

| Application | Primarily applied in software development, IT, and project management contexts. | Applied in manufacturing, healthcare, and service industries. |

| Change Management | Emphasizes managing change at the project and team level, focusing on delivering working software. | Focuses on systemic change that optimizes the entire process or organization for value delivery. |

| Measurement of Success | Success is often measured by delivering valuable software, customer satisfaction, and team dynamics. | Success is measured by eliminating waste, efficiency gains, and improvements in the value stream. |

Lean software development extends the principles of Lean manufacturing and management to the software development process, adapting its core tenets to focus on value, efficiency, and eliminating waste in the development cycle. By applying Lean principles, software development teams aim to deliver high-quality software faster and more efficiently while being more responsive to customer needs. Here are key capabilities and practices in Lean software development:

1. Eliminate Waste

In software development, waste refers to any activity that does not add value to the customer. This includes unnecessary code, documentation, waiting times, task switching, and defects. Lean emphasizes identifying and eliminating these wastes to streamline the development process.

2. Amplify Learning

Software development is a continuous learning process. Lean encourages practices such as code reviews, pair programming , and iterative development cycles to facilitate constant learning and improvement. Teams are encouraged to experiment and learn from successes and failures alike.

3. Decide as Late as Possible

Lean software development advocates for delaying decisions until the last responsible moment. This approach allows for more flexible and informed decision-making, taking advantage of more up-to-date information and reducing the risk of costly changes.

4. Deliver as Fast as Possible

Speed and efficiency are core to Lean. This capability focuses on reducing the time from customer request to delivering a feature, known as the lead time. Continuous Integration (CI) and Continuous Deployment (CD) help automate and streamline the development process, enabling faster releases and quicker feedback loops with customers.

5. Empower the Team

Lean promotes giving autonomy to development teams, trusting them to make decisions and solve problems within their domain. This empowerment boosts morale and encourages a sense of ownership, which can lead to more innovative solutions and improvements in the development process.

6. Build Integrity In

Software integrity refers to the cohesion and overall quality of the software product, including its usability, maintainability, and functionality. Lean advocates for building quality into the product from the beginning through practices like Test-Driven Development (TDD), automated testing, and refactoring. This ensures the product meets customer needs and reduces the need for rework.

7. Optimize the Whole

Instead of focusing solely on individual components or stages of development, Lean emphasizes optimizing the entire value stream, from idea to delivery. This approach encourages teams to break down silos and collaborate across functions to improve the flow of work and ensure that efforts are aligned with delivering customer value.

8. Use of Lean Tools

Tools like Kanban boards and Value Stream Mapping are used to visualize work, manage flow, and identify bottlenecks in the software development process. These tools support Lean principles by making the process more transparent and helping teams focus on continuous improvement.

Get hands-on experience through applied learning with 13 projects, 12 simulation tests, 18 case studies , and several PDUs in our Lean Six Signma Expert program. Get help with Simplilearn's JobAssist program to enhance your interview skills.

1. Manufacturing: Streamlining Production Lines

Challenge: A manufacturing plant faced issues with production bottlenecks, excess inventory, and long lead times, leading to delayed deliveries and increased costs.

Lean Solution: The plant implemented several Lean tools, including Value Stream Mapping, to identify and eliminate non-value-adding steps in production. They introduced a Kanban system to manage inventory better and align production with actual demand, and they reorganized the layout of the production floor to minimize unnecessary movement (transportation waste).

Outcome: These changes led to a smoother flow of materials through the production line, reduced inventory levels by 30%, improved on-time delivery rates, and significantly decreased lead times.

2. Healthcare: Improving Patient Flow in Emergency Rooms

Challenge: An emergency department (ED) faces long waiting times, patient dissatisfaction, and staff stress due to overcrowded conditions and inefficient patient flow.

Lean Solution: The ED used Lean methodologies to map the patient journey and identify bottlenecks. They then implemented changes such as standardizing intake processes, optimizing staff allocation based on peak times, and establishing fast-track lanes for patients with minor conditions.

Outcome: The changes reduced average patient waiting times by 40%, improved patient satisfaction scores, and improved staff morale, allowing for more efficient resource use and reduced crowding.

3. Software Development: Accelerating Feature Delivery

Challenge: A software development team struggled with slow release cycles caused by lengthy QA processes, code integration issues, and frequent rework.

Lean Solution: The team adopted Lean principles, implementing Continuous Integration (CI) and Continuous Deployment (CD) practices to automate testing and deployment. They used Kanban to manage workflow and limit work-in-progress, which helped identify and address bottlenecks more efficiently.

Outcome: These adjustments significantly reduced the time from code commit to deployment, with release cycles shortening from months to weeks. Faster feedback and correction loops also improved the overall quality of the software.

4. Retail: Enhancing Customer Service and Inventory Management

Challenge: A retail chain was experiencing high levels of stockouts and overstock in various locations, leading to lost sales and high inventory costs.

Lean Solution: The retailer applied Lean tools to analyze their supply chain and inventory management processes. They implemented a pull-based replenishment system, supported by accurate demand forecasting and real-time inventory tracking, to ensure that stock levels were aligned with actual sales patterns.

Outcome: Implementing these Lean principles resulted in a 50% reduction in stockouts, decreased excess inventory, and improved customer satisfaction due to the higher availability of products.

Value Stream Mapping (VSM) is a critical tool within Lean manufacturing that helps visualize and understand the flow of materials and information as a product goes through the value stream. Value Stream Mapping contributes to Lean manufacturing by:

- Providing a Visual Overview: It offers a clear visual representation of the flow of materials and information, making it easier to identify bottlenecks and waste.

- Facilitating Team Collaboration: Creating a value stream map encourages cross-functional collaboration and a shared understanding of the process.

- Highlighting Opportunities for Improvement: By mapping out the current state, organizations can more easily envision a future state with reduced waste and improved efficiency.

- Supporting Continuous Improvement: VSM is not a one-time activity but a tool for ongoing improvement efforts, helping organizations continuously refine and optimize their processes.

From manufacturing to healthcare and software development to retail, Lean principles empower organizations to streamline operations, enhance efficiency, and deliver unparalleled value to customers. Lean methodology optimizes processes and fosters a culture of excellence and innovation by focusing on waste elimination, continuous improvement, and value creation.

The Lean Six Sigma Expert course offers a great pathway for professionals and organizations eager to master these principles and drive significant operational improvements. This master's program provides an in-depth exploration of Lean and Six Sigma methodologies, equipping participants with the tools and knowledge to lead and sustain Lean transformations in their organizations.

1. What is the Lean methodology?

The lean methodology is an approach to organizational efficiency that focuses on maximizing customer value while minimizing waste. It emphasizes continuous improvement and the efficient use of resources to streamline processes, reduce costs, and increase quality.

2. What are the 5 principles of Lean methodology?

The 5 principles of Lean methodology are:

- Define Value from the customer's perspective.

- Map the Value Stream to identify and eliminate waste.

- Create Flow by ensuring smooth progress of value-creating steps.

- Establish Pull by producing only what is needed, when it is needed.

- Pursue Perfection through continuous improvement.

3. What is Lean vs Agile?

Lean focuses on efficiency and waste reduction throughout an organization, primarily in manufacturing and production contexts. Agile, on the other hand, is a project management approach used mainly in software development. It emphasizes flexibility, customer feedback, and adaptive planning. Both aim to improve outcomes but differ in application and emphasis.

4. What are types of lean tools?

Types of Lean tools include:

- Value Stream Mapping: Visualizing steps to deliver a product or service to identify waste.

- Kanban: A visual workflow management method to optimize the flow of work.

- 5S: A workplace organization method (Sort, Set in order, Shine, Standardize, Sustain).

- Kaizen: Continuous improvement through small, incremental changes.

Our Quality Management Courses Duration And Fees

Explore our top Quality Management Courses and take the first step towards career success

| Program Name | Duration | Fees |

|---|---|---|

| Cohort Starts: | 12 weeks | € 2,250 |

| 10 weeks | € 1,249 |

Get Free Certifications with free video courses

Quality Management

Lean Management

Learn from Industry Experts with free Masterclasses

How Lean Six Sigma Skyrockets Your Career Trajectory in 2024

Program Overview: Become a Lean Six Sigma Expert with UMass Amherst

Recommended Reads

Free eBook: Guide To Scrum Methodology

Project Management Methodologies

Agile Vs Waterfall: Choosing the Best Methodology

Free eBook: Guide to the Six Sigma Certifications

Your Complete Guide to Six Sigma Methodology

What is Agile? Understanding Agile Methodology and Principles in Software Development

Get Affiliated Certifications with Live Class programs

- PMP, PMI, PMBOK, CAPM, PgMP, PfMP, ACP, PBA, RMP, SP, and OPM3 are registered marks of the Project Management Institute, Inc.

Explore Lean Thinking and Practice / What is Lean?

What is Lean?

Lean is a way of thinking about creating needed value with fewer resources and less waste. and lean is a practice consisting of continuous experimentation to achieve perfect value with zero waste. lean thinking and practice occur together..

Lean thinking always starts with the customer. What does the customer value ? Or, stated differently and in a way that invites concrete action, what problem does the customer need to solve?

Lean practice begins with the work — the actions that directly and indirectly create value for the customer — and the people doing that work. Through ongoing experimentation, workers and managers learn by innovating in their work — be it physical or knowledge work — for increasingly better quality and flow, less time and effort, and lower cost. Therefore, an organization characterized by lean practice is highly adaptive to its ever-changing environment when compared to its peers because of the systematic and continuous learning engendered by lean thinking and practice .

A lean enterprise is organized to keep understanding the customer and their context, i.e., specifying value and looking for better ways to provide it:

- through product and process development,

- during fulfillment from order through production to delivery, and

- through the product’s and/or service’s use cycle from delivery through maintenance and upgrades to recycling.

Lean Transformation Framework

Lean enterprises, both ongoing firms and startups, endlessly address fundamental questions of purpose, process, and people :

- What is the value-driven purpose? Or what is the problem to solve?

- What is the work to be done (to solve the problem)?

- What capabilities are required (to do the work to solve the problem)?

- What management system — operating system and leadership behaviors — is required?

- What basic thinking, including mindsets and assumptions, are required by the organization as a purpose-driven socio-technical system?

Lean thinking has a moral compass: respect for the humanity of customers, employees, suppliers, investors, and our communities with the belief that all can and will be better off through lean practices. Lean is not dogmatic. It’s not a rigid, unchanging set of beliefs and methods. Instead, it progresses in the context of specific situations. There is no endpoint as long as value is imperfectly created, and waste exists. Learn about the brief history of lean thinking and practice .

Let’s elevate the work. Celebrate it. And, with that, let’s treat it—the work—with the deep respect it deserves. – John Shook

How can lean thinking help you?

From executive coaching in strategy development, deployment, and alignment to engaging employees to create a culture of problem-solving and everything in between, see how lean thinking and practice can elevate your organization’s performance.

I want to know how lean thinking can help me with

- Product and Process Development

- Administration / Support

- Problem-Solving

- Executive Leadership

- Line Management

Explore articles about

Subscribe to get the very best of lean thinking delivered right to your inbox, privacy overview.

- Sign Up Free

THE LEAN WAY BLOG

The five principles of lean.

by Doanh Do

5th August 2017

Lean was born out of manufacturing practices but in recent time has transformed the world of knowledge work and management. It encourages the practice of continuous improvement and is based on the fundamental idea of respect for people. Womack and Jones defined the five principles of Lean manufacturing in their book “The Machine That Changed the World”. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. The next sections provides a detailed overview of each principle.

The Five Lean Principles Explained:

Figure 1. The Five Lean Principles

1. Define Value

To better understand the first principle of defining customer value, it is important to understand what value is. Value is what the customer is willing to pay for. It is paramount to discover the actual or latent needs of the customer. Sometimes customers may not know what they want or are unable to articulate it. This is especially common when it comes to novel products or technologies. There are many techniques such as interviews, surveys, demographic information, and web analytics that can help you decipher and discover what customers find valuable. By using these qualitative and quantitative techniques you can uncover what customers want, how they want the product or service to be delivered, and the price that they afford.

2. Map the Value Stream

The second Lean principle is identifying and mapping the value stream. In this step, the goal is to use the customer’s value as a reference point and identify all the activities that contribute to these values. Activities that do not add value to the end customer are considered waste. The waste can be broken into two categories: non-valued added but necessary and non-value & unnecessary. The later is pure waste and should be eliminated while the former should be reduced as much as possible. By reducing and eliminating unnecessary processes or steps, you can ensure that customers are getting exactly what they want while at the same time reducing the cost of producing that product or service.

3. Create Flow

After removing the wastes from the value stream, the following action is to ensure that the flow of the remaining steps run smoothly without interruptions or delays. Some strategies for ensuring that value-adding activities flow smoothly include: breaking down steps, reconfiguring the production steps, leveling out the workload, creating cross-functional departments, and training employees to be multi-skilled and adaptive.

4. Establish Pull

Inventory is considered one of the biggest wastes in any production system. The goal of a pull-based system is to limit inventory and work in process (WIP) items while ensuring that the requisite materials and information are available for a smooth flow of work. In other words, a pull-based system allows for Just-in-time delivery and manufacturing where products are created at the time that they are needed and in just the quantities needed. Pull-based systems are always created from the needs of the end customers. By following the value stream and working backwards through the production system, you can ensure that the products produced will be able to satisfy the needs of customers.

5. Pursue Perfection

Wastes are prevented through the achievement of the first four steps: 1) identifying value, 2) mapping value stream, 3) creating flow, and 4) adopting a pull system. However, the fifth step of pursuing perfection is the most important among them all. It makes Lean thinking and continuous process improvement a part of the organizational culture. Every employee should strive towards perfection while delivering products based on the customer needs. The company should be a learning organization and always find ways to get a little better each and every day.

Applying the Principles

The five Lean principles provide a framework for creating an efficient and effective organization. Lean allows managers to discover inefficiencies in their organization and deliver better value to customers. The principles encourage creating better flow in work processes and developing a continuous improvement culture . By practicing all 5 principles, an organization can remain competitive, increase the value delivered to the customers, decrease the cost of doing business, and increase their profitability. Use The Lean Way to enable teams of all types and across all levels of your organization to apply Lean principles to their work. Get started with a free 14 day trial.

ABOUT THE AUTHOR

Doanh Do is graduate of UC Berkeley. He is a co-founder of Paramount Decisions, Inc. and The Lean Way, Inc. Through his research and software companies, Doanh's goal is to help the AEC industry be more innovative and lower the barrier to applying the best practices in Lean Construction. Paramount Decisions helps companies make better design decisions through Choosing By Advantages. The Lean Way helps companies start and sustain their lean and continuous improvement efforts.

YOU MIGHT ALSO LIKE...

The 8 wastes of lean, what is muda, mura, and muri, lean culture, 6 tips to starting and sustaining your continuous improvement efforts, continuous improvement, 5 benefits of continuous improvement.

Guide: Lean Principles

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Lean Principles, rooted in the Toyota Production System, represent a transformative approach to business efficiency and customer value creation. These principles are not just a set of guidelines but a comprehensive methodology for process improvement and waste minimization. Central to Lean is the idea of delivering more value to customers using fewer resources.

This guide delves into the core principles of Lean – Identify Value, Map the Value Stream, Create Flow, Establish Pull, and Seek Perfection – and explores their practical applications in various business contexts. It also outlines a structured approach to implementing these principles, ensuring a sustained and impactful transformation in organizational processes.

What are the Lean Principles?

The Principles of Lean are fundamentally about creating more value for customers with fewer revenues. The Lean Principles originated from the Toyota Production System (TPS), These principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value.

The Five Principles of Lean are: 1. To Identify Value, 2. Mapping the Value Stream, 3. Creating Flow, 4. Establishing a Pull System, and 5. Seeking Perfection.

The reality is that in any production process, only a small percentage of activities are value-added from the customer’s point of view.

For example: in a bakery, value-adding activities include baking and decorating cakes, which directly meet customer needs. However, time spent waiting for ingredients to arrive or excessive inventory management is non-value-adding , as they don’t contribute directly to the creation or enhancement of the final product for the customer.

Identifying and eliminating or reducing the impact of non-value-adding activities is key to businesses being Lean. These non-value-adding activities are referred to as waste, or the Japanese term “ muda ,” and are known by eight popular categories: transportation, inventory, motion, waiting, overproduction, overprocessing, defects, and skills.

Lean Principles are industry-agnostic, meaning they can be applied to any business or process and are not just suitable for the automotive sector. Over the past 70 years, there have been plenty of examples of Lean being implemented in diverse sectors such as healthcare, software development, retail and service businesses.

The Five Core Lean Principles

1. Identify Value

The first core principle of lean is Identifying Value , this is rooted in a deep understanding of what the customer truly values. It is not about what the business thinks is valuable, but what the customer perceives as valuable from your product or service.

An example of this might be: A service industry, like a hotel, which might analyze customer feedback to prioritize amenities and services that guests value the most.

To understand more about identifying customer value, take a look at our Critical to Quality (CTQ) guide.

2. Map the Value Stream

The second principle of lean is mapping the value stream. This involves conducting a full analysis of the entire process flow, identifying each action taken in the course of creating and delivering a product or service.

Common tools used in the step include: flow charts or value stream maps . For example, a manufacturer would chart the journey from raw materials to finished goods, identifying any step that doesn’t add value, like unnecessary movement of materials or delays in production.

To understand more about creating a value stream map, take a look at our Value Stream Map (VSM) guide.

3. Create Flow

The third principle of lean is to create flow. This is a key step that involves ensuring the identified value-added steps flow in an efficient sequence and ensuring that the product or service flows smoothly without interruption.

This could involve redesigning a workspace for efficiency, cross-training employees for greater flexibility, or adopting just-in-time inventory to ensure materials are available exactly when needed.

4. Establish Pull

The fourth principle of lean is to establish a pull system. A pull system aims to produce only what the customer needs and when they need it. This is in contrast to the traditional push system in which most businesses operate, where products are made in anticipation of demand. However, the nature of holding excess stock in inefficient and not a lean method to run a business.

5. Seek Perfection

Finally, the fifth principle of lean is to seek perfection. The pursuit of perfection is an ongoing process of continuous improvement, often referred to as Kaizen . This involves constantly looking for ways to make processes more efficient and effective in delivering value. This could mean regular brainstorming sessions for process improvement, continuous training programs, or implementing a feedback loop where employees are encouraged to suggest improvements.

Implementing the Lean Principles in an Organization

Implementing Lean principles in an organization is a transformative process that requires strategic planning, dedicated involvement from all levels of staff, and a commitment to continuous improvement.

Step 1: Assessment and Planning

Before implementing the lean principles, it is important to understand and assess the current state of the business processes. This step would involve mapping out the current process with a process map or value stream map from start to finish and identifying inefficiencies, redundancies, and any steps that do not add value to the customer.

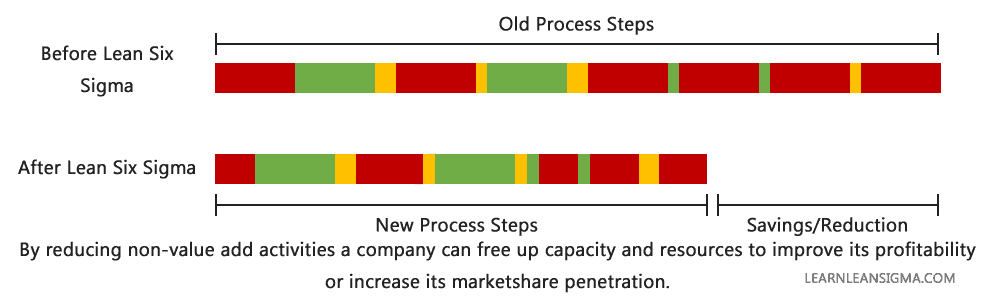

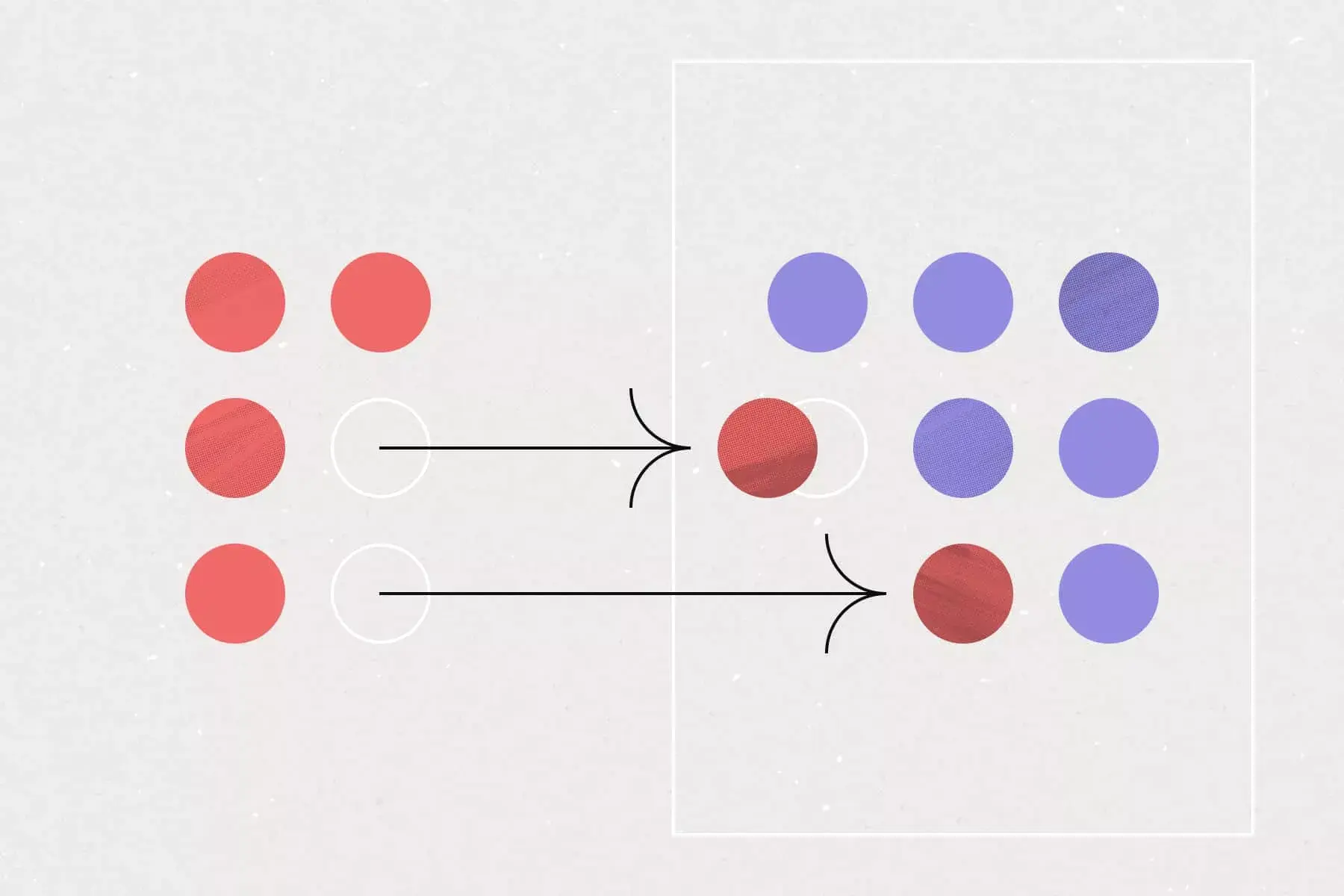

Take the following image as an example of the potential current and future states of the process. This theoretical visualisation is always the aim with the lean principles to reduce and remove as much waste as possible from the process and increase customer value.

Value add analysis example

Key to the success of the assessment and planning of implementing lean is engaging and involving all relevant stakeholders in the process, including leadership, employees and possible customers, to ensure there is a clear understanding of the process and to secure buy-in for lean initiates to follow.

Step 2: Training and Engagement

A vital element to the success of implementing lean in a business, and in my experience, often the most overlooked element, is training and engagement. Educating employees about lean principles and methodologies is important. Furthermore, this should involve more than just theoretical knowledge but also practical insights into how these principles can be applied to their specific roles, making the role relevant to them.

The goal of training and education should be to develop a culture where lean thinking becomes natural to them. This includes problem-solving , waste reduction, and continuous improvement.

This can be achieved by using engagement strategies such as workshops, seminars, and my favourite hands-on training sessions on real workplace problems. In effect, learners learn by doing while being guided by a qualified facilitator.

Step 3: Pilot Projects

Once you have the foundations of areas to be improved and a team that is trained and engaged, the next step is to start improving with small pilot projects. The key is to start small and expand as confidence and competency in the business grow.

Once those initial projects have been completed and stakeholders see visible results this will further help develop the culture of lean. Going big on projects that fail will only increase resistance to future projects.

Use these pilot projects as learning experiences. Gather data, analyze results, and understand what works and what doesn’t. After successful pilot projects, plan to scale up lean implementations to more extensive areas or other processes within the organization.

Step 4: Continuous Monitoring and Adaption

Step three was just the start of a never-ending cycle of improvement, therefore, step 4 is about continuous monitoring and adaption. The business should continue to regularly monitor the progress of lean initiatives and use key performance indicators (KPIs) to measure success and identify areas for improvement.

You should encourage feedback from employees and customers.This feedback is valuable for understanding the impact of changes and uncovering new areas for improvement. You should also be prepared to adapt strategies and approaches based on the results and feedback. Lean is about continuous learning and adaptation.

Step 5: Building a Lean Culture

Finally and constantly, you should continue to develop a lean culture in the business, as lean is not a quick fix but a long-term commitment that requires long-term effort and dedication.

To ensure this is successful, leadership must actively support and participate in lean initiatives and set an example for the rest of the organization. Additionally, employees should be empowered to take initiative, suggest improvements, and make decisions that align with Lean principles. Lean thinking should be integrated into every aspect of the organization, from daily routines to strategic decisions.

Implementing Lean Principles is a journey of continuous improvement, requiring a strategic approach and a commitment to cultural change within an organization. It begins with a thorough assessment and planning, identifying areas of waste and inefficiencies. The process then evolves through training and engaging employees, undertaking pilot projects, and continuously monitoring and adapting strategies.

Ultimately, the success of Lean implementation lies in embedding these principles into the organizational culture, fostering a mindset of efficiency, customer focus, and perpetual improvement. Through this journey, businesses can achieve remarkable improvements in process efficiency, customer satisfaction, and overall value creation.

- Kilpatrick, J., 2003. Lean principles. Utah Manufacturing Extension Partnership , 68 (1), pp.1-5.

- Poppendieck, M., 2011. Principles of lean thinking. IT Management Select , 18 (2011), pp.1-7.

- Gothelf, J., 2013. Lean UX: Applying lean principles to improve user experience . ” O’Reilly Media, Inc.”.

Q: What is the first step in implementing Lean in my organization?

A: The first step in implementing Lean is conducting an educational assessment to gauge the current level of Lean knowledge within your organization. This will help you identify knowledge gaps and form the basis for targeted training and education.

Q: How do I identify 'Value' as per Lean principles?

A: Identifying ‘Value’ in Lean involves understanding what the customer considers valuable. This can be achieved through customer surveys, interviews, and data analysis. The aim is to discern what the customer is willing to pay for, and then focus your efforts on delivering that value efficiently.

Q: Can Lean principles be applied to service industries like healthcare?

A: Absolutely, Lean principles are not confined to manufacturing and can be applied across various sectors, including service industries like healthcare. For example, Virginia Mason Medical Center successfully implemented Lean to reduce patient wait times and improve safety protocols.

Q: What metrics can be used to measure the success of a Lean project?

A: metrics for measuring lean success vary depending on the objectives. however, common key performance indicators (kpis) include cycle time, defect rates, customer satisfaction scores, and operational costs. these metrics help quantify the improvements achieved through lean implementation., q: is lean only about cost-cutting.

A: While cost savings are often a benefit, Lean is not solely about cutting costs. The primary focus of Lean is to create value for the customer by streamlining processes and eliminating waste. This often leads to increased efficiency, improved quality, and enhanced customer satisfaction, in addition to cost savings.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website www.learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

- Get Posts Sent via Email

- Contributors

- Most Popular

- Most Commented

- Lean Comedy

- Podcast Home

- Browse Episodes

- Episode Collections

- Podcast Home & Subscribe

- Lean Whiskey

- My Favorite Mistake

- Practicing Lean

- Toyota Kata Podcast

- Featured Videos

- YouTube Channel

- Via MarkGraban.com

- About Mark Graban

- About the Blog

- What is “Lean”?

- Standardized Work

- Privacy Tools

- Healthcare Improvement

- Lean-Focused Blogs

- Lean Healthcare Blogs

- Other Blogs

- Lean Resources

- Contact Form

- Get Posts via Email

- Mark’s Newsletter

Lean 101: Understanding the Basics of Lean Thinking and Methodology — What is Lean?

New to lean we'll try to help define lean.

… for healthcare, manufacturing, and other settings.

“Lean Healthcare” Overview:

Download the 1st Chapter of Lean Hospitals

If you're visiting the blog because of a search and you're not sure what this whole “Lean” thing is about, we'll try to introduce you. Keep in mind that this is just a starting point. There's a reason that dozens of books have been written about Lean. It's not easy to fully understand all in one night. I have been learning about it for more than 15 years 20 years since 1994. Not that I'm holding myself up as the #1 expert on the topic. I learn about Lean every day and I try to get better by “ Practicing Lean .”

The Typical Goals of Lean

The goals of organizations that are practicing Lean are pretty consistent across industries. Their goals are to simultaneously improve:

- Delivery (reducing delays & waiting through a process)

The goal is to provide long-term success for an organization and for everybody involved — customers, employees, owners, suppliers, and other stakeholders.

In manufacturing, “delivery” might mean on-time delivery, or shipping the right product in the right quantity at the right time. In healthcare, it means providing the right care at the right place at the right time, which means reducing waiting times for appointments and reducing waits and delays when in a healthcare facility.

What Lean Is and Is Not

Lean is not about being skinny and it's not about “cutting to the bone.” Lean is about having the right resources in place to do the right work for the customer, with the right quality, at the right time.

Lean is not “mean” (although the words rhyme, unfortunately). Lean is respectful toward everybody who participates in a system, including customers, employees, suppliers, the community, etc.

Lean does not mean cutting heads in the name of cutting costs (see “Lean is not mean”). Lean is probably the best alternative strategy to the old approach of layoffs and “cost cutting. “

Lean is not an acronym (“LEAN”).

Lean is NOT…

- NOT just a few tools to use

- NOT a group of best practices to copy

- NOT just a bunch of projects to conduct

- NOT experts telling you what to do

- NOT a way to drive layoffs

- NOT just a process improvement methodology

- NOT just for frontline staff

- NOT “part of Six Sigma”

- NOT just about speed & efficiency

- NOT pressuring people to hit certain metrics

- NOT a silver bullet or an easy transformation

Lean is…

“ Lean ” is the set of management practices based on the Toyota Production System (TPS). The phrase “Lean Production” was coined by a group of MIT researchers who wrote the book The Machine That Changed the World .

Lean Production is basically the same thing as:

- Lean Manufacturing

- Lean Enterprise

- Lean Thinking

- Lean Healthcare

- Lean Government

- Lean Startups

It's the same principles and mindsets, applied for different purposes given the industry.

Lean has been applied in manufacturing (factories, product design, and administrative functions) as well as service industries (including healthcare, banking, and government). The U.S. Army has an active “lean six sigma” program underway as of 2011.

See my article on LinkedIn:

“Lean” is Not Just for Manufacturing – It Applies to Knowledge Work of All Types, Too

The Toyota Production System , a.k.a. Lean is defined as having two primary pillars:

- Just-in-Time (improving flow)

- Quality at the source

Jamie Bonini, the President of TSSC , defines TPS as:

“We define TPS as an organizational culture of highly engaged people solving problems or innovating to drive performance.”

Jamie also describes TPS as mainly a philosophy , as described in this post:

Lean: The Toyota Production System is Mainly About the Philosophy

The Toyota Europe website has a page that describes the philosophy as they see it, and this page decribes the Toyota Way 2020 .

Another way of defining Lean (“ The Toyota Way ” management system) has two parts:

- Eliminate waste and non-value-added activity (NVA) through continuous improvement

- Practice respect for people

The opposite of waste is value-added activity, which has a special Lean definition. An activity is “value added” if, and only if, these three conditions are met:

- The customer must be willing to pay for the activity

- The activity must change the “form, fit, or function” of the product, making it closer to the end product that the customer wants and will pay for (in healthcare, this can mean moving the care process forward, such as comfort, diagnosis, treatment, education, prevention)

- The activity must be done right the first time.

We aren't just reducing waste, we're also trying to provide the most value to customers through Lean methods.

In healthcare, I generally think of “value” in a patient care process to be the work that involves things like:

- Comforting the patient

- Examining them

- Diagnosing them

- Treating them

- Educating them

- Preventing future illness

Respect and Leadership

“ Respect for people ” is much more complex to define than it might seem. Lean isn't about “being nice” and smiling all of the time. Respect means you challenge people to do their best because you believe in them and it also means that you collaborate and work together with them in improvement (the practice of “ kaizen “).

See this article about “respect for people in healthcare ,” as well.

Lean leadership is about enabling and empowering people. Lean leadership is about helping people grow professionally and personally, allowing them to take pride in their work. Lean leadership recognizes how a system operates. Lean leadership doesn't set targets for people, go back to their office, and then yell at people when they don't hit those targets. Lean leaders spend time coaching people. They spend very little time in their office. They lead people and see what is actually happening rather than managing metrics and reading reports.

Much of the “people side” of lean was adapted from the teachings of the American professor and consultant W. Edwards Deming , who taught Toyota and other Japanese companies after World War II. Lean was also adapted from Toyota's study of the early practices of Henry Ford and the Ford Motor Company. Note the emphasis on “early.” Lean is not strictly a Japanese invention nor is its use limited to Japan or Japanese companies.

Lean Resources, Reading, and Listening

If you're new to Lean, welcome. I hope you'll enjoy learning more about it.

Also, check out the Lean Enterprise Institute and their “What is Lean?” pages.

Toyota's corporate website has a nice set of TPS pages . As does Toyota Europe .

I also invite you to check out my series of Lean Blog Interviews Podcast episodes, which include interviews with leading Lean thinkers, writers, and leaders.

Some of my posts on core Lean concepts and my “ best posts” on this topic .

- Lean isn't about “Quality” and “Productivity”

- My Thoughts on Standardized work

- Common Sense on Offshoring and Lean

- Putting the “Continuous” Back into Continuous Improvement

This page is going to grow and evolve over time. It is hard to write a succinct definition of Lean that captures all of its principles and philosophies (but here's a post where we all tried ).

Get New Posts Sent To You

Check your inbox or spam folder to confirm your subscription.

EVEN MORE NEWS

Why Two-Year Comparisons in MLB Stats Fall Short: The Power of...

Lean Whiskey #47: Decriminalizing Medical Errors, Mouse Jiggling, and New (to...

Ryan McCormack’s Operational Excellence Mixtape: July 12, 2024

Popular category.

- Interviews 500

- Mixtape 143

- Lean Whiskey 47

- Lean Blog Interviews

- Lean Blog Audio

- Privacy Policy

Flexible project management

Knowledge, all in one place

Jira Service Management

High-velocity service delivery

Unlock enterprise knowledge

Jira Product Discovery New

Capture & prioritize ideas

Compass New

Optimize software health

Enhanced cloud security

Quick, async video updates

Collaborative code repos

Organized & visualized work

Enterprise strategy alignment

Ship high-quality, innovative software faster

Collaborative strategies for marketing success

Deliver exceptional operations and support services.

Integrations

Connect thousands of apps to your Atlassian products

Case studies & stories powered by teamwork

Compliant solutions for the public sector

Enterprise-grade & highly performant infrastructure

Our deeply integrated, reliable & secure platform

Trust center

Ensure your data’s security, compliance & availability

Customer Support

Ask questions, report bugs & give us feedback

Find Partners

Consulting, training & product customization support

Migration Program

Step-by-step guidance for your Atlassian cloud migration

Learn and expand your skill set for all things Atlassian

- Microservices

- Agile project management

- Lean process improvement

Lean process improvement: What is it and how to apply it to projects

Browse topics.

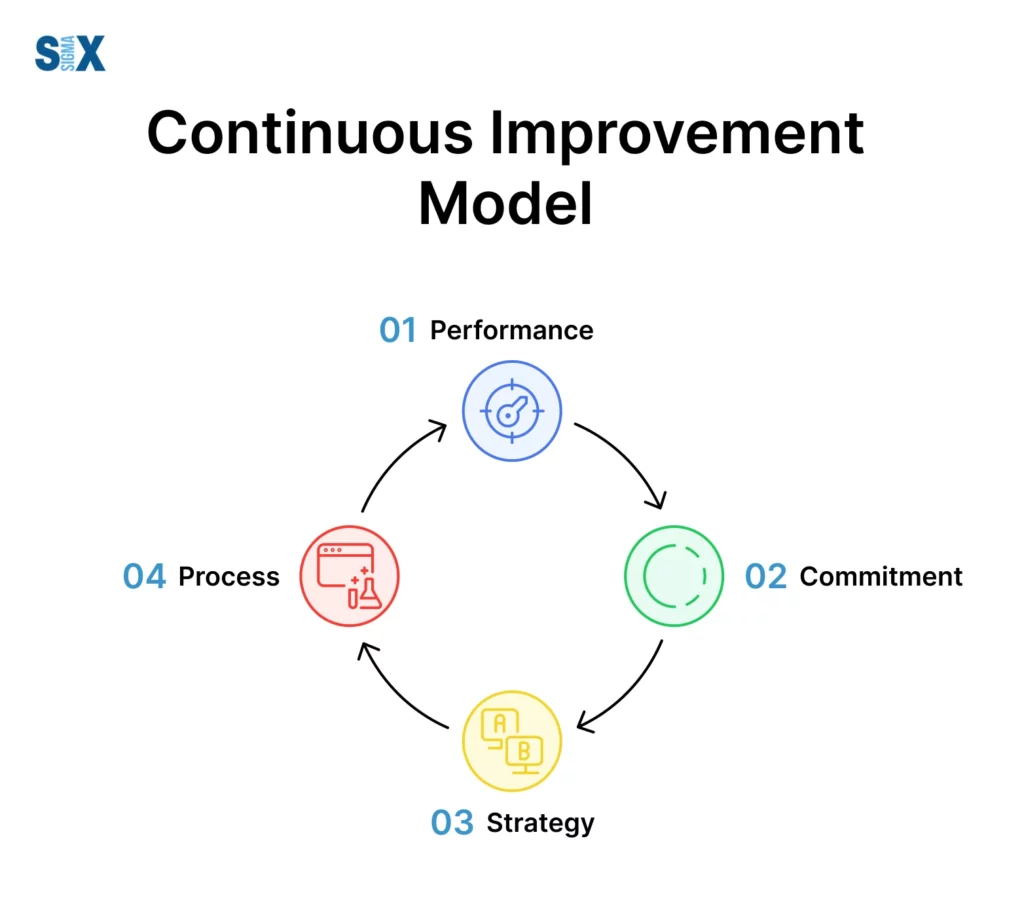

Continuous improvement is a fundamental principle of Lean methodology , and Lean process improvement focuses on eliminating wasteful activities to streamline a company’s processes. It involves analyzing and assessing projects while they are underway and after completion to identify opportunities for improvement. This method seeks to create a systematic approach to allow teams to deliver more customer value via the continuous improvement cycle.

This article breaks down the Lean process improvement methodology and compares it with other software development methodologies, such as Agile and DevOps principles.

What is Lean process improvement?

Lean process improvement focuses on eliminating waste from processes so that the team only works on tasks that create customer value. It’s a cycle of continuous improvement that ensures a team stays Lean.

This isn’t a one-and-done approach. Doing this practice correctly will help sustain momentum and keep projects moving forward. The key objective is to create a systematic means of delivering customer value faster. It’s a long-term practice that works best if the entire company adopts it.

Benefits of Lean process improvement

Lean process improvement ensures teams are only working on tasks that will deliver value to customers, saving the company resources and money.

Lean process improvement has the following benefits:

Increased efficiency : Analyzing and improving your process allows you to better estimate future sprints’ deadlines and deliverables.

Better collaboration : Continual improvement fosters cross-collaboration company-wide. It encourages teams to communicate issues or opportunities for process improvement.

Improved morale : Streamlined and stable processes create more wins for a team, improving morale.

Decreased waste : Teams only work on essential tasks, decreasing time wastage.

Growth mindset : Lean management encourages everyone to continually seek improvement.

Satisfied customers : If a company consistently delivers value, customers become advocates for its products.

Ability to remain relevant : The ability to shift priorities and adapt prevents stagnation.

How to apply Lean process improvement within projects

Using Lean principles to improve processes is a process in itself. Here’s how to integrate it within a company in four easy steps:

1. Determine potential areas for improvement

Gather your team and take an honest look at your current processes. Identify areas where the processes are not meeting your team’s needs and could benefit from change.

For instance, you might have an ongoing blocker each time you move from design to development. Investigate what is causing that blocker. Is it miscommunication? Are there skill gaps? Does the design team need more support?

Consider visualizing your workflow with a Kanban board . A root cause analysis template can also guide you through this process.

2. Identify potential solutions

Once you pinpoint improvement areas, involve the team in finding potential solutions. Their experience often allows them to generate effective solutions. Challenge traditional ways of doing things and seek to break the “how we’ve always done it” mindset.

From these potential solutions, determine which ones are most feasible. Then, choose a focus area and develop an action plan to implement the ideas.

3. Implement improvements

Implementing change can be challenging. There may be initial resistance. However, proper planning and project collaboration make this process easier and help teams work together.

Using a project plan template ensures cross-functional collaboration because it outlines the plan of attack and helps determine the best way to implement solutions. You can map out the project’s logistics beforehand so everything is crystal clear. Having a plan also ensures the involvement and collaboration of stakeholders, as they’ll be able to track and monitor progress.

4. Monitor outcomes

Implementing solutions is not the end of the process. It is crucial to monitor performance and gather data to determine if the solutions resulted in improvements. It is also essential to identify the reasons behind the success or failure of the solutions.

Analyzing this data can reveal areas that require further refinement. This is normal, as the process is cyclical; the goal is to continue to improve and refine the solutions.

Now that we’ve looked at how to implement this methodology, let’s see how it compares with other methods.

Lean process improvement vs. value stream management

Value stream management (VSM) is another Lean methodology focused on improvement. It aims to improve how teams deliver high-quality customer experiences by focusing on the speed at which customers receive updates and whether they value the changes.

VSM examines a company’s overall product development and delivery system. It seeks to enhance the end-to-end process of delivering the product, service, or experience. Lean process management, however, is task-oriented and focuses on specific processes.

Teams can rely on Jira to streamline workflows and processes and scale their team collaboration. Jira Align helps companies visualize value streams across teams, set up process flow automation, and align work with business needs.

Lean process improvement vs. Agile

Agile project management , another Lean methodology, is an iterative process for software development with continuous releases based on customer feedback.

Agile has four key values and 12 guiding principles, which put people over processes and tools. They strive to improve communication within teams and between customers.

Like VSM, Agile project management aims for overall process improvement. It achieves this through ongoing communication between end-users and the development team.

Scrum and Kanban are two Agile frameworks. Scrum is designed for teams that deliver work on a regular cadence or work in short, time boxed periods called sprints. Kanban, however, is designed for teams that limit work-in-progress and focus on a continuous flow of work. Jira supports both agile methodologies, making it easier for software teams to organize work, stay aligned, and build better products.

Lean process improvement vs. DevOps

DevOps refers to a cross-functional team of operations and developers who communicate, share feedback, and collaborate throughout the development process. DevOps principles focus on increasing the speed of software development through cross-functional collaboration. It breaks the walls between the development team and the operations team. DevOps uses a customer-centric method to make process improvements using feedback loops with end-users. Lean process management relies on the internal team rather than the customer.

Open DevOps , powered by Jira, can help software teams implement this methodology and keep them focused on delivering value to customers. It integrates easily with Atlassian and partner tools so teams can focus on building and operating software.

Can you apply all of these principles at once?

Yes, these four Lean methodologies build upon each other, allowing a company to improve its processes and productivity. Lean process improvement can refine internal processes and eliminate wasteful activities. VSM can hone the customer value stream, delivering better quality products. Agile keeps teams nimble and responsive to change. And DevOps increases team empathy for customers.

The outcomes of these methodologies result in improved customer experience and satisfaction

Jira for Lean process improvement

Jira simplifies the complexities of software development, supports teams at every stage of the delivery lifecycle, and enables teams to stay lean. Contextual insights empower teams to build and train muscles to continuously learn and improve their way of working. Scrum and Kanban boards give your team full visibility into what’s next so you can continuously deliver maximum output in minimal time. With Jira as the backbone of collaboration, all teams can stay in lockstep with each other and the rest of the organization.

Jira can also help large organizations visualize value streams across teams. You can further automate your process flows and ensure work aligns with strategic business objectives. All of this will help you stay lean as you track investments, streamline operations, and uncover roadblocks. That way, your team will deliver continuous value to customers.

Lean process improvement: Frequently asked questions

What are the 5 lean principles.

The five Lean principles are the cornerstone of the Lean process. They originated in Japan’s automotive industry and are used in various industries. Let’s break them down:

Define value : Determine which activities provide customer value.

Map the value stream : Visualize customer value activities to keep projects on task.

Create flow : Remove any roadblocks before they interrupt the team’s flow.

Establish a pull system : Produce according to actual demand rather than forecasted demand.

Seek continuous improvement : Look for opportunities to improve processes and find efficiencies.

What are the most common Lean process improvement techniques?

Here are a few common techniques to improve processes using Lean principles:

Kanban : This technique uses cards to organize and visualize team activities. It allows the entire team to see what’s moved from “to-do” to “done.”

5 Whys : Asking why five times helps identify the root cause of a problem. It allows you to constantly drill down on an issue until you get to its initial cause.

WIP Limits : In this technique, the project manager sets the limit of work that can exist in any given workflow. Having WIP limits prevents the team from getting overloaded and stressed.

What are the most important things to keep in mind when using a Lean process improvement approach?

To achieve continuous improvement, a team must strive to reduce and eliminate waste as an ongoing practice. It’s not a one-and-done approach; it’s a cyclical process of improvement. Best practices also recommend focusing on a singular process issue at a time rather than tackling them all at once. It’s easier to solve one issue at a time than to spread out your efforts and try to address all the problems at the same time.

- Share on Facebook

- Share on Twitter

- Share on LinkedIn

Lean principles: advancing DevOps efficiency

Explore the power of Lean Principles and DevOps in streamlining project management, enhancing efficiency, and delivering value faster.

What is Lean Methodology?

Explore the principles of lean methodology and how it can be applied to your business operations to improve efficiency and deliver more value to customers.

What Is Lean Management? Basics Explained.

Lean management has become a universal management tool for delivering value and optimizing workflows. Explore the Lean methodology along with its benefits and find examples.

- What Is Lean Management?

The 5 Principles of Lean

What Is Shared Leadership?

- What Is Lean Manufacturing?

- What Is Value in Lean?

- 7 Wastes of Lean

- What Is Mura?

- What Is Muri?

- What Is 5S?

- What Is the Cost of Delay?

- What Is Value Stream Mapping?

- What Is a Pull System?

- What Is a Bottleneck?

- Just-in-Time Manufacturing

- Implementing a Kanban Pull System

- Pull System on the Portfolio Level

- What Is Kaizen?

- What Is Continuous Improvement?

- Built-In Quality Management

- What Is the Poka-Yoke Technique?

- What Is the PDCA (Plan Do Check Act) Cycle?

- 5 Whys: The Ultimate Root Cause Analysis Tool

- Gemba Walk: Where the Real Work Happens

- A3 Problem-Solving: Fight the Root Cause

- How To Perform Root Cause Analysis?

- Root Cause Analysis Tools

- What Is a Pareto Chart?

- What Is a Scatter Diagram?

- What Is a Fishbone Diagram?

- What Is Hoshin Kanri?

- What Is Hoshin Kanri Catchball?

- Demystifying the Hoshin Kanri X Matrix

- The Lean Transformation Model Explained

- Lean Transformation Roadmap - 8 Comprehensive Steps

- What Is Cycle Time?

- What Is Little's Law?

- What Is Takt Time?

- What Is Heijunka?

- What Is Jidoka?

- What Is Andon?

- Lean Six Sigma Principles

- Lean Six Sigma Tools

- Lean Six Sigma Implementation

- What Is Six Sigma?

- What Is DMADV?

- What Is DMAIC?

- Lean Project Management

Lean Management Definition

Lean management is a systematic approach to optimizing efficiency by minimizing waste and maximizing value for the customer. Originating from the Toyota Production System (TPS), it is characterized by a relentless pursuit of improvement and a focus on value creation through waste elimination.

The main goal of Lean management is to improve efficiency and effectiveness by reducing the time spent on non-value-adding activities and optimizing the flow of work. Such waste in Lean can include overproduction, waiting time, unnecessary transportation, excess inventory, unnecessary processing, and defects. The Lean concept is successfully applied to any business or production process, from manufacturing to healthcare, engineering, and software development.

The Birth of Lean Management

Lean management has its roots in the Toyota Production System , which was established in the late 1940s. In the late 1940s, when Toyota put the foundations of Lean manufacturing , they aimed to reduce processes that don’t bring value to the product. By doing so, they succeeded in achieving significant improvements in productivity, efficiency, cycle time, and cost efficiency. The success of the TPS at Toyota led to the spread of Lean thinking and the implementation of Lean principles around the world. Today, Lean management is used in a wide range of industries and organizations and has evolved to include a variety of tools, techniques, and approaches.

Indeed, the term "lean production" was made up by John Krafcik (former CEO of Google’s self-driving car project Waymo) in his 1988 article "Triumph of the Lean Production System". His studies formed the data behind James P. Womack’s 1990 book "The Machine That Changed the World: The Story of Lean Production".

What Are the 5 Lean Management Principles?

Five Lean principles

1. Identify Value

What does every company strive to do? To offer a product or service that a customer is ready to pay for. To do so, a company needs to add value defined by its customers’ needs.

The value lies in the problem you are trying to solve for the customer. More specifically, in the part of the solution that your customer is actively willing to pay. Any other activity or process that doesn’t add value to the product is considered a waste.

In Lean, value is the first thing you need to identify. So, first, decide what you want to deliver, then move on to the next step.

2. Value Stream Mapping

This is the point where you need to map your company's workflow. It should include all actions and people involved in delivering the product to the customer. By doing so, you will be able to identify which parts of the process bring no value.

Applying the Lean principle of value stream mapping will show you where value is being generated and in what proportion different parts of the process do or do not produce value.

When you have your value stream mapped, it will be much easier for you to see which processes are owned by which teams and who is responsible for measuring, evaluating, and improving those processes. This big picture will enable you to detect the steps that don’t bring value and eliminate them.

3. Create a Continuous Workflow

After you master your value stream, you need to ensure that each team's workflow remains smooth. Keep in mind that it may take a while.

Developing a product or service will often include cross-functional teamwork. Bottlenecks and interruptions may appear at any time. However, by breaking down work into smaller batches and visualizing the workflow, you can easily detect and remove process roadblocks.

4. Create a Pull System

Implementing a pull system guarantees a stable flow of work and enables teams to complete tasks more swiftly and easily. As a lean strategy, a pull system reduces waste in the production cycle by initiating new tasks only when there is a clear demand. This lets you optimize resources’ capacity and deliver products or services only if there is an actual need.

Let’s take a restaurant, for example. You go there and order a pizza. The baker pulls your order and starts making your pizza. He doesn’t prepare tons of dishes in advance because there isn’t actual demand, and these tons of dishes can turn into a waste of resources.

5. Continuous Improvement

After going through all the previous steps, you have already built your Lean management system. However, don’t forget to pay attention to this last step, probably the most important one.

Remember, your system is not isolated and static. Problems may occur with any of the previous steps. This is why you need to make sure that employees on every level are involved in continuously improving the process.

There are different techniques to encourage continuous improvement. For example, every team may have a daily stand-up meeting to discuss what has been done, what needs to be done, and possible obstacles - an easy way to process improvements daily.

What Are the Benefits of Lean Management?

Lean management can help organizations and teams alike to create a stable work system with a higher chance of improving overall performance. Here's a list of the major advantages you can benefit from when introducing Lean.

Increased employee engagement and focus : Lean encourages employees to identify and solve problems leading to increased engagement and focus on activities that bring value.

Improving productivity and efficiency : By eliminating waste and streamlining processes, Lean management can help organizations become more efficient and productive, allowing them to produce more with the same or fewer resources.

Faster time to market : By establishing a pull system, a Lean management system helps organizations deliver work only if there is actual demand and reduces their lead times.

Improved quality : Lean management places a strong emphasis on identifying and eliminating defects, which can help to improve product and service quality.