- Previous Article

- Next Article

Utilization of corn husk for tissue papermaking

- Article contents

- Figures & tables

- Supplementary Data

- Peer Review

- Reprints and Permissions

- Cite Icon Cite

- Search Site

Natalia Suseno , Marisca E. Gondokesumo , Puspita R. Permatasari; Utilization of corn husk for tissue papermaking. AIP Conf. Proc. 11 November 2021; 2338 (1): 040019. https://doi.org/10.1063/5.0067417

Download citation file:

- Ris (Zotero)

- Reference Manager

The demand of tissue papers is increasing with the population increase. This will definitely increase the need of wood fibers as the main raw material. However, due to the wood shortages, there have been many attempts to use non- wood fibers as substitutes for papermaking. In Indonesia, corn production has gradually increased for the last 5 years, hence it also has an impact on the raising in the amount of corn husk waste. Corn husk has a high cellulose content which suitable to be used as a raw material for tissue papermaking. In this experiment, soda pulping process was conducted to remove out lignin. The resulting tissue paper will be added with additives that have antimicrobial properties of chitosan and mangosteen peel for the purpose of increasing the tensile strength or absorption of water. The aim of this research is to study the effect of depending variables (temperature and NaOH concentration) on chemical composition (cellulose and lignin content), and physical properties including water absorption and tensile strength.The research was started with the initial process of removing the lignin content in the pulp by pretreating delignification using the sodium hydroxide (NaOH) process with several variations in concentration (4–10%), and temperature (60–90°C) for 1.5 hours. To obtain tissue with a good physical condition, it has been influenced by the optimum chemical composition containing high cellulose and low lignin content, high tensile strength and water absorption. The optimum conditions for tissue paper in this study were at 90°C and 4% of NaOH concentration. The next step will be to vary the composition of the additive in order to obtain the effect of physical properties (tensile strength and water absorption).

Sign in via your Institution

Citing articles via, publish with us - request a quote.

Sign up for alerts

- Online ISSN 1551-7616

- Print ISSN 0094-243X

- For Researchers

- For Librarians

- For Advertisers

- Our Publishing Partners

- Physics Today

- Conference Proceedings

- Special Topics

pubs.aip.org

- Privacy Policy

- Terms of Use

Connect with AIP Publishing

This feature is available to subscribers only.

Sign In or Create an Account

New Research

This “Tissue” Paper Is Made From Real Tissue

Made from powdered organs, the flexible paper could be used as a sophisticated bandage during surgery

Jason Daley

Correspondent

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/8e/ec/8eec902a-29d2-436c-98cf-1487cfb51937/origami_.jpg)

When Adam Jakus was a postdoc at Northwestern University he accidentally spilled some “ink” he'd created from powdered ovaries intended for 3-D printing. Before he could wipe up the mess, it solidified into a thin, paper-like sheet, reports Charles Q. Choi at LiveScience . That led to a lab-bench epiphany.

“When I tried to pick it up, it felt strong,” Jakus says in a press release . “I knew right then I could make large amounts of bioactive materials from other organs. The light bulb went on in my head.”

Jakus, along with the same team that developed a 3-D printed mouse ovary earlier this year, began experimenting with the concept. According to a video , they began collecting pig and cow organs from a local butcher shop, including livers, kidneys, ovaries, uteruses, hearts and muscle tissue.

The team then used a solution to strip the cells from the tissues, leaving behind a the scaffolding material of collagen proteins and carbohydrates. After freeze-drying the matrix, they powdered it and mixed it with materials that allowed them to form it into thin sheets. The research appears in the journal Advanced Functional Materials .

“We’ve created a material we call 'tissue papers' that’s very thin, like phyllo dough, made up of biological tissues and organs,” says Ramille Shah, head of the lab where the research took place, in the video. “We can switch out the tissue we use to make the tissue paper—whether that be derived from liver or muscle or even ovary. We can switch it out very easily and make a paper out of any tissue or organ.”

According to the press release, the material is very paper-like and can be stacked in sheets. Jakus even folded some into origami cranes. But the tissue paper’s most important property is that it is biocompatible and allows for cellular growth. For instance, the team seeded the paper with stem cells, which attached to the matrix and grew over four weeks.

That means the material could potentially be useful in surgery, since paper made of muscle tissue could be used as a sophisticated Band-Aid to repair injured organs. “They're easy to store, fold, roll, suture and cut, like paper," Jakus tells Choi. “Their flat, flexible nature is important if doctors want to shape and manipulate them in surgical situations.”

Northwestern reproductive scientist Teresa Woodruff was also able to grow ovary tissue from cows on the paper, which eventually began producing hormones. In the press release, she explains that a strip of the hormone-producing tissue paper could be implanted, possibly under the arm, of girls who have lost their ovaries due to cancer treatments to help them reach puberty.

The idea of using extracellular matrices, hydrogels or other material as a scaffolding to bioprint organs like hearts and kidneys is being investigated by labs around the world. In 2015, a Russian team claimed they printed a functional mouse thyroid . And this past April, researchers were able to b ioprint a patch derived from human heart tissue that they used to repair the heart of a mouse.

Get the latest stories in your inbox every weekday.

Jason Daley | | READ MORE

Jason Daley is a Madison, Wisconsin-based writer specializing in natural history, science, travel, and the environment. His work has appeared in Discover , Popular Science , Outside , Men’s Journal , and other magazines.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- My Bibliography

- Collections

- Citation manager

Save citation to file

Email citation, add to collections.

- Create a new collection

- Add to an existing collection

Add to My Bibliography

Your saved search, create a file for external citation management software, your rss feed.

- Search in PubMed

- Search in NLM Catalog

- Add to Search

Experimental dataset supporting the physical and mechanical characterization of industrial base tissue papers

Affiliations.

- 1 Fibre Materials and Environmental Technologies Research Unit (FibEnTech-UBI), Universidade da Beira Interior, Rua Marquês d'Ávila e Bolama, Covilhã 6201-001, Portugal.

- 2 Forest and Paper Research Institute (RAIZ), R. José Estevão, Eixo, Aveiro 3800-783, Portugal.

- PMID: 33145380

- PMCID: PMC7593524

- DOI: 10.1016/j.dib.2020.106434

Tissue paper is defined by its physical and mechanical properties, namely: high softness, low grammage, high bulk and high liquid absorption capacity. It is expected that the production of tissue paper will continue to grow, which increases the importance of better understanding the processes involved in its production as well as its optimization [1]. The experimental data presented in this article, are the physical-mechanical characterization of a group of 13 industrial base tissue papers, which were collected at the end of the tissue paper machine on Portuguese factories. These samples vary in grammage, composition and creping [2], enabling a later evaluation of the crepe type [3] and its relationship with the final properties of the tissue paper.

Keywords: Absorption capacity; Fiber morphology; Industrial base tissue paper; Mechanical characterization; Structural properties; Tissue softness.

© 2020 The Author(s).

PubMed Disclaimer

Conflict of interest statement

The authors declare that they have no known competing financial interests or personal relationships which have, or could be perceived to have, influenced the work reported in this article.

Similar articles

- FEM Analysis Validation of Rubber Hardness Impact on Mechanical and Softness Properties of Embossed Industrial Base Tissue Papers. Vieira JC, Mendes AO, Ribeiro ML, Vieira AC, Carta AM, Fiadeiro PT, Costa AP. Vieira JC, et al. Polymers (Basel). 2022 Jun 18;14(12):2485. doi: 10.3390/polym14122485. Polymers (Basel). 2022. PMID: 35746060 Free PMC article.

- Challenges in computational materials modelling and simulation: A case-study to predict tissue paper properties. Morais FP, Curto JMR. Morais FP, et al. Heliyon. 2022 May 2;8(5):e09356. doi: 10.1016/j.heliyon.2022.e09356. eCollection 2022 May. Heliyon. 2022. PMID: 35540931 Free PMC article.

- Embossing Pressure Effect on Mechanical and Softness Properties of Industrial Base Tissue Papers with Finite Element Method Validation. Vieira JC, Mendes AO, Ribeiro ML, Vieira AC, Carta AM, Fiadeiro PT, Costa AP. Vieira JC, et al. Materials (Basel). 2022 Jun 18;15(12):4324. doi: 10.3390/ma15124324. Materials (Basel). 2022. PMID: 35744382 Free PMC article.

- Mechanical Metamaterials on the Way from Laboratory Scale to Industrial Applications: Challenges for Characterization and Scalability. Fischer SCL, Hillen L, Eberl C. Fischer SCL, et al. Materials (Basel). 2020 Aug 14;13(16):3605. doi: 10.3390/ma13163605. Materials (Basel). 2020. PMID: 32824029 Free PMC article. Review.

- Organic and mechanical properties of Cervidae antlers: a review. Picavet PP, Balligand M. Picavet PP, et al. Vet Res Commun. 2016 Dec;40(3-4):141-147. doi: 10.1007/s11259-016-9663-8. Epub 2016 Sep 12. Vet Res Commun. 2016. PMID: 27618827 Review.

- Enhanced water absorption of tissue paper by cross-linking cellulose with poly(vinyl alcohol). Ferreira ACS, Aguado R, Bértolo R, Carta AMMS, Murtinho D, Valente AJM. Ferreira ACS, et al. Chem Zvesti. 2022;76(7):4497-4507. doi: 10.1007/s11696-022-02188-y. Epub 2022 Apr 8. Chem Zvesti. 2022. PMID: 35431412 Free PMC article.

- Raunio Simulation of creping pattern in tissue paper. Nordic Pulp Paper Res. J. 2012;27:375–381. doi: 10.3183/NPPRJ-2012-27-02-p375-381. - DOI

- Anukul P., Khantayanuwong S., Somboon P. Development of laboratory wet creping method to evaluate and control pulp quality for tissue. TAPPI J. 2015;14:7.

- Ramasubramanian M.K., Shmagin D.L. An experimental investigation of the creping process in low-density paper manufacturing. J. Manuf. Sci. Eng. 2000;122:576. doi: 10.1115/1.1285908. - DOI

- J.C. Vieira, A. de O. Mendes, A.M. Carta, E. Galli, P.T. Fiadeiro, A.P. Costa, Impact of Embossing on Liquid Absorption of Toilet Tissue Papers. 15 (2020) 3888–3898. doi:10.15376/biores.15.2.3888-3898. - DOI

- ISO 12625-6:2005 Tissue Paper and Tissue Products - Part 6: Determination of Grammage (2005).

LinkOut - more resources

Full text sources.

- Elsevier Science

- Europe PubMed Central

- PubMed Central

- Citation Manager

NCBI Literature Resources

MeSH PMC Bookshelf Disclaimer

The PubMed wordmark and PubMed logo are registered trademarks of the U.S. Department of Health and Human Services (HHS). Unauthorized use of these marks is strictly prohibited.

Please fill the all required fields....!!

World of TISSUES

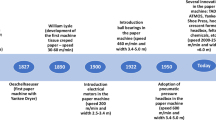

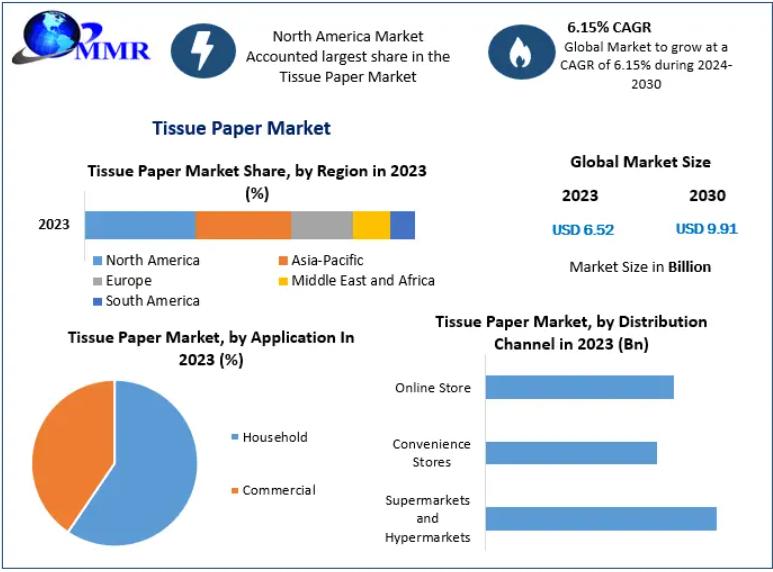

The tissues sector has boomed over the last few years. With a move to more luxurious tissue paper and ultra absorbent paper towels the industry has been able to increase the tissue prices and create new brands to retain consumers. Add to this growing market in developing countries and a drive to innovate, and there are very positive signals for the future of tissues. The tissue segment has become one of the most important segments of the paper industry in developed countries. It produces one of the most highly valued and appreciated, though not necessarily talked about, paper products.

Tissue paper or simply tissue is a lightweight paper or, light crêpe paper. Tissue can be made both from virgin and recycled paper pulp. Tissue papers are the most common thing that we use in our daily life from cleaning, dusting, wrapping and personal use.

As far as the history of tissue paper industry goes, although paper had been known as a wrapping and padding material in China since the 2nd century BC, the first use of toilet paper in human history dates back to the 6th century AD, in early medieval China. If we could travel back in time to 1391, we would encounter a Chinese emperor who demanded the first paper sheets sliced to be placed in his outhouse. The first “official” toilet paper was introduced in China measuring a whopping 2 ft X 3 ft each.

An important move towards the production and distribution of modern toilet tissue paper came from a teacher in Philadelphia in 1907. Concerned about a mild cold epidemic in her classroom, she blamed it on the fact that all students used the same cloth towel. She proceeded to cut up paper into squares to be used by her class as individual towels, a revolutionary idea. Arthur Scott of Scott Paper Company heard about this teacher and decided he would try to sell the carload of paper. He perforated the thick paper into small towel-size sheets and sold them as disposable paper towels. Later he renamed the product Sani-Towel and sold them to hotels, restaurants, and railroad stations for use in public washrooms.

In 1931, Scott introduced the first paper towel for the kitchen and created a whole new grocery category. He made perforated rolls of "towels" thirteen inches wide and eighteen inches long. That is how paper towels were born. It was to take many years, however, before they gained acceptance and replaced cloth towels for kitchen use.

Production of the tissue paper

Tissue paper is produced on a paper machine that has a single large steam heated drying cylinder (yankee dryer) fitted with a hot air hood. The raw material is paper pulp. The yankee cylinder is sprayed with adhesives to make the paper stick. Creping is done by the yankee's “doctor blade” that is scraping the dry paper off the cylinder surface. The crinkle (creping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the yankee and final section of the paper machine and paper pulp characteristics.

The highest water absorbing applications are produced with a through air drying (TAD) process. These papers contain high amounts of NBSK and CTMP. This gives a bulky paper with high wet tensile strength and good water holding capacity. The TAD process uses about twice the energy compared with conventional drying of paper.

The properties are controlled by pulp quality, creping and additives (both in base paper and as coating). The wet strength is often an important parameter for tissue paper.

Applications of tissue paper

Tissue paper has number of applications and they come in number of varieties such as hygienic tissues, facial tissues, paper towels, wrapping tissues, toilet tissues, table napkins etc.

- Facial tissue has been used for centuries in Japan, in the form of washi (??) or Japanese tissue, as described in this 17th-century European account of the voyage of Hasekura Tsunenaga. In 1924 facial tissue as it is known today was first introduced by Kimberly-Clark as Kleenex. It was invented as a means to remove cold cream. Kimberly-Clark also introduced pop-up, colored, printed, pocket, and 3-ply facial tissues.

- Paper towels are the second largest application for tissue paper in the consumer sector. This type of paper has usually a basis weight of 20 to 24 g/m2. Normally such paper towels are two-ply. This kind of tissue can be made from 100% chemical pulp to 100% recycled fibre or a combination of the two. Normally, some long fibre chemical pulp is included to improve strength. In 1951, William E. Corbin, Henry Chase (scientist), and Harold Titus began experimenting with paper towels in the Research and Development building of the Brown Company in Berlin, New Hampshire. By 1922, Corbin perfected their product and began mass-producing it at the Cascade Mill on the Berlin/Gorham line. This product was called Nibroc Paper Towels (Corbin spelled backwards). In 1931, the Scott Paper Company of Philadelphia, Pennsylvania introduced their paper towel for kitchens. They are now the leader of the manufacture of paper towels.

- W rapping tissue is a type of thin, translucent paper used for wrapping presents and cushioning fragile items.

- Table napkin, or face towel (also in Canada, the United Kingdom, Australia, New Zealand and South Africa: serviette) is a rectangle of cloth used at the table for wiping the mouth and fingers while eating. In the United Kingdom and Canada both terms, serviette and napkin, are used. In certain places, serviettes are those made of paper whereas napkins are made of cloth.

- Rolls of toilet paper have been available since the end of the 19th century. Today, more than 20 billion rolls of toilet tissue are used each year in Western Europe. Joseph Gayetty is widely credited with being the inventor of modern commercially available toilet paper in the United States.

Gayetty's paper, first introduced in 1857, was available as late as the 1920s. Gayetty's Medicated Paper was sold in packages of flat sheets, watermarked with the inventor's name. Seth Wheeler of Albany, New York, obtained the earliest United States patents for toilet paper and dispensers, the types of which eventually were in common usage in that country, in 1883. Moist toilet paper was first introduced in the United Kingdom by Andrex in the 1990s and in the United States by Kimberly-Clark in 2001 (in lieu of bidets which are rare in those countries).

With so many varieties available, tissue industry is growing leaps and bounds. Out of the world's estimated production of 21 million tonnes of tissue, Europe produces approximately 6 million tonnes tissue every year .

The European tissue market is worth approximately 10 billion Euros annually and is growing at a rate of around 3%. The European market represents around 23% of the global market. In North America, people are consuming around three times as much tissue as in Europe. In Europe, the industry is represented by The European Tissue Symposium (ETS), a trade association. The members of ETS represent the majority of tissue paper producers throughout Europe and about 90% of total European tissue production. ETS was founded in 1971 and is based in Brussels since 1992.

Finally, the paper tissue industry, along with the rest of the paper manufacturing sector, has worked hard to minimise its impact on the environment. Recovered fibres now represent some 46.5% of the paper industry’s raw materials. The industry relies heavily on biofuels (about 50% of its primary energy) and it is highly energy-efficient. EDANA, the trade body for the non-woven absorbent hygiene products industry (which includes products such as household wipes for use in the home) has reported annually on the industry’s environmental performance since 2005. The industry’s impact on the environment is in fact, relatively small.

All in all, the tissue sector continues to be a growth industry worldwide, offering new opportunities for companies to expand. Recently, there has been a great deal of interest, in particular, in the use of recovered fibres to manufacture new tissue paper products. However, whether this is actually better for the environment than using new fibres is open to question.

Quick Links

Related Articles

Pilot Paper Machine

Nanotechnology in the pulp and paper industry

About: Devid - Head of Sales

Cras sit amet nibh libero, in gravida nulla. Nulla vel metus scelerisque ante sollicitudin. Cras purus odio, vestibulum in vulputate at, tempus viverra turpis. Fusce condimentum nunc ac nisi vulputate fringilla. Donec lacinia congue felis in faucibus.

Top Viewed Articles

Publish your article.

Thank you for your interest in publishing article with Packaging-Labelling. Our client success team member will get in touch with you shortly to take this ahead.

you're here, check out our informative and insightful article. Happy Surfing!

Client Success Team (CRM),

- Architecture and Design

- Asian and Pacific Studies

- Business and Economics

- Classical and Ancient Near Eastern Studies

- Computer Sciences

- Cultural Studies

- Engineering

- General Interest

- Geosciences

- Industrial Chemistry

- Islamic and Middle Eastern Studies

- Jewish Studies

- Library and Information Science, Book Studies

- Life Sciences

- Linguistics and Semiotics

- Literary Studies

- Materials Sciences

- Mathematics

- Social Sciences

- Sports and Recreation

- Theology and Religion

- Publish your article

- The role of authors

- Promoting your article

- Abstracting & indexing

- Publishing Ethics

- Why publish with De Gruyter

- How to publish with De Gruyter

- Our book series

- Our subject areas

- Your digital product at De Gruyter

- Contribute to our reference works

- Product information

- Tools & resources

- Product Information

- Promotional Materials

- Orders and Inquiries

- FAQ for Library Suppliers and Book Sellers

- Repository Policy

- Free access policy

- Open Access agreements

- Database portals

- For Authors

- Customer service

- People + Culture

- Journal Management

- How to join us

- Working at De Gruyter

- Mission & Vision

- De Gruyter Foundation

- De Gruyter Ebound

- Our Responsibility

- Partner publishers

Your purchase has been completed. Your documents are now available to view.

Online quality evaluation of tissue paper structure on new generation tissue machines

At present, the tissue paper manufacturing is mostly based on the dry crepe technology. During the last decade, the manufacturers have introduced new tissue machines concepts that increase the softness, bulk, and absorption capacity. Such machines produce a strong regular three-dimensional (3D) structure to the sheet before the Yankee cylinder. At present, the quality of the 3D structure is not evaluated, or it is evaluated only subjectively at the mill. This is mostly because of the difficulties to separate reliably the regular 3D pattern from other variations. This paper introduces a frequency analysis based method which separates the surface profile variances in tissue paper to the creping, to the regular 3D pattern and to the residual variation. The 3D surface profiles and their variances were determined online with the photometric stereo method. We show that the introduced analysis method evaluates the variance portions reliably and the results are consistent with the visual perception of the 3D surfaces. In one particular product, the regular 3D pattern explains 74 % of total surface variance; the creping explains 10 % and residual variations 16 %. Furthermore, the creping and residual variances are quite stable over time whereas the variance of the regular 3D pattern fluctuates significantly.

Conflict of interest: The authors do not have any conflicts of interest to declare.

Archer, S., Furman, G. (2005) Embedded sheet Structures-Impact on tissue properties. Tissue World, Nice, France. Search in Google Scholar

Archer, S., Furman, G., Von Drasek, W. (2010) Image analysis to Quantity crepe structure, Proceedings, PaperCon. Tappi, Atlanta, USA. Search in Google Scholar

Boudreau, J. (2013) New methods for evaluation of tissue creping and the importance of coating, paper and adhesion. PhD Thesis, Karlstad University, Karlstad, Sweden. Search in Google Scholar

Frankot, R., Chellappa, R. (1988) A method for enforcing integrability in shape from shading algorithms. IEEE Trans. Pattern Anal. Mach. Intell. 10(4):435–446. 10.1109/34.3909 Search in Google Scholar

Hansson, P., Fransson, P. (2004) Color and shape measurement with a three color photometric stereo system. Appl. Opt. 43(20):3971–3977. 10.1364/AO.43.003971 Search in Google Scholar PubMed

Hollmark, H., Ampulski, R.S. (2004) Measurement of tissue paper softness: A literature review. Nord. Pulp Pap. Res. J. 19(3):345–353. 10.3183/npprj-2004-19-03-p345-353 Search in Google Scholar

Ihalainen, H., Marjanen, K., Mäntylä, M., Kosonen, M. (2012) Developments in camera based on-line measurement of paper. Control systems, New Orleans, USA. Search in Google Scholar

Ikehata, S., Wipf, D., Matsushita, Y., Aizawa, K. (2014) Photometric stereo using sparse Bayesian regression for general diffuse surfaces. IEEE Trans. Pattern Anal. Mach. Intell. 36(18):16–31. 10.1109/TPAMI.2014.2299798 Search in Google Scholar PubMed

Kamps, R.J., Behnke, J.S, Chen, F.-J., Kressner, B.E., Nielsen, J.G. (1994) Method for making soft tissue. U.S. Patent 5743999 A (Filed Jun. 15, 1994). Search in Google Scholar

Klerelid, I., Thomasson, O. (2008) Advantage (TM) NTT: low energy, high quality. Tissue World, Shanghai, China. Search in Google Scholar

Lauri, M., Ihalainen, H. (2010) Measuring periodic patterns in noisy spatial data, Measurement Systems and Process Improvement MSPI 2010-Enbis IMEKO TC 21 Workshop. Teddington, UK. Search in Google Scholar

Mettänen, M. (2010) Measurement of print quality: joint statistical analysis of paper topography and print defects. PhD Thesis, Tampere University of Technology, Tampere, Finland. Search in Google Scholar

Peli, E. (1990) Contrast in Complex Images. J. Opt. Soc. Am. 7(10):2032–2040. 10.1364/JOSAA.7.002032 Search in Google Scholar PubMed

Raunio, J.-P. (2014) Quality Characterization of Tissue and Newsprint Paper based on Image Measurements; Possibilities of On-line Imaging. PhD Thesis, Tampere University of Technology, Tampere, Finland. Search in Google Scholar

Raunio, J.-P., Ritala, R. (2012) Simulation of creping pattern in tissue paper. Nord. Pulp Pap. Res. J. 27(2):375–381. 10.3183/npprj-2012-27-02-p375-381 Search in Google Scholar

Scherb, T., Walkenhaus, H., Herman, J., Silva, L. (2005) Advanced Dewatering System. U.S. Patent 20070256806 A1 (Filed Jan. 19, 2005). Search in Google Scholar

Smith, M.L., Smith L.N. (2005) Dynamic Photometric Stereo - A New Technique for Moving Surface Analysis. Image Vis. Comput. 23(9):841–852. 10.1016/j.imavis.2005.01.007 Search in Google Scholar

Tagare, H.D., deFigueiredo, R.J.P. (1991) A theory of photometric stereo for a class of diffuse non-lambertian surfaces. IEEE Trans. Pattern Anal. Mach. Intell. 13(1):33–52. 10.1109/34.67643 Search in Google Scholar

Welch, P.D. (1967) The use of fast Fourier transform for the estimation of power spectra: a method based on time averaging over short, modified periodograms. IEEE Trans. Audio Electroacoust. 15(2):70–73. 10.1109/TAU.1967.1161901 Search in Google Scholar

Woodham, R.J. (1980) Photometric method for determining surface orientation from multiple images. Opt. Eng. 19(1):139–144. 10.1117/12.7972479 Search in Google Scholar

Woodham, R.J. (1994) Gradient and curvature from photometric-stereo method including local confidence estimation. J. Opt. Soc. Am. 11(11):3050–3068. 10.1364/JOSAA.11.003050 Search in Google Scholar

© 2018 Walter de Gruyter GmbH, Berlin/Boston

- X / Twitter

Supplementary Materials

Please login or register with De Gruyter to order this product.

Journal and Issue

Articles in the same issue.

Perceived Vs Recorded Quality of Tissue Paper: A Thematic Analysis of Online Customer Reviews

- September 2019

- Thesis for: Master of Science in Industrial Engineering and Management

- Advisor: Magnus Berglund

- Linköping University

Discover the world's research

- 25+ million members

- 160+ million publication pages

- 2.3+ billion citations

- Frank Duckhorn

- J RETAILING

- J MARKETING

- Eugene W. Anderson

- Donald R. Lehmann

- INFORM MANAGE-AMSTER

- Chaojiang Wu

- Klaus Mundt

- Michael J. Groves

- Johan Kullander

- Recruit researchers

- Join for free

- Login Email Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google Welcome back! Please log in. Email · Hint Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google No account? Sign up

Renewable Bioproducts Institute

Pulp, paper, packaging and tissue.

From tree to tissue, or to package, or to stationery, magazine or newspaper or thousands of other products—pulping liberates fibers from woody plants and rearranges them into a consistently formed end products. The science rests in efficient processes that conserve energy and raw materials while producing the desired product.

In the 1950s, the kraft chemical pulping process became the dominant technology for isolating wood fiber from chips. While this produces strong pulp and efficient recovery of raw materials and energy, the yield is below ideal and has an inherent capital intensity for the investor. RBI researchers are developing improvements in next generation pulping to address these challenges.

We are exploring pretreatment options to make fiber separation more efficient, and improving yields. A number of catalysis options, including biochemical methods, are under investigation. Biorefining processes are converting cellulose and lignin into sugars, fuels, and chemical intermediates and feedstocks.

Advanced processes under investigation include modeling tools for evaporation of water from spent pulping liquor and techniques to eliminate equipment fouling. Advanced membrane technologies are expanding capabilities for cost-effective separation of organics and inorganics from spent pulping liquor. This opens up new possibilities for reducing energy intensity and even more efficient reuse of process streams.

Understanding the pathways of erosion and corrosion, and developing means to eliminate them, can save millions in maintenance and replacement costs, as well as lost production. Analysis and testing capabilities include thermodynamic prediction and modeling of corrosion processes and recommendations for improved metallurgy to address the aggressive environments in these applications.

At RBI, we continue to explore the seemingly limitless possibilities of paper. As the successor to the Institute of Paper Chemistry founded in 1929 by leaders of the pulp and paper industry, our mission is to create a body of knowledge and advance the industry. Our researchers are working to understand and manage new ways in which: • molecular structures in fibers can be coaxed to bond (or not) • the structure of a sheet can be formed • moisture, gases, oil and grease can be absorbed or repelled • inks can be accepted or released • formation and de-watering will improve manufacturing and energy efficiency These mechanisms and more are creating inspiration for new products of the 21st century. Operational excellence is our goal. In taking the industry into this new era of technology and application of science, we continue to develop paper-based substrates and biocomposites for applications in electronics used in smart packaging; high-strength, light-weight panels for aviation and automotive uses; advanced technologies for paper, packaging and films; strength and fracture characteristics of paper for packaging; superamphiphobic paper for water and grease repellency; and auxetic papers that expand when stretched. Innovative technologies have resulted in new applications, products and materials from renewable, sustainable forest biomass.

New Product Innovations

RBI continues to address challenges and opportunities in fiber engineering and paper physics to yield a step-change in paper/packaging product performance. For those members who utilize the fundamental knowledge embedded in our faculty and staff, RBI creates a competitive edge and insight into the future of forest products.

In the area of consumer products, technologies such as light dry crepe and through-air drying, non-woven technologies such as spunbond, meltblown and spunlace are included in the expertise of our faculty. The application of biomaterials will be expanded in consumer products within the next few years across the spectrum of disposables and single-use plastics to create a more sustainable offering within this segment of the industry.

Some of the new product innovations in paper board include smart packaging, coating solutions, printed electronics, renewable binders and adhesives and other chemicals with high value to customers, consumers and society as a whole. The future advances and technologies in these areas are sure to touch every aspect of daily life around the globe.

Areas of Expertise: Advanced Packaging Technology New Coatings & Barriers Dissolving Pulp & Regenerated Cellulose Paper & Board Mechanics Printing Technology Pulp and Paper Manufacturing Tissue

Key Contacts:

For more information on RBI’s initiatives on Pulp, Paper, Packaging, and Tissue, and how to get involved, please contact one of our key contacts working in the area.

Chris Luettgen

Professor of the Practice, School of Chemical and Biomolecular Engineering, Director, Undergraduate Pulp & Paper Certificate Program Email: [email protected]

RBI Initiative Lead: Process Efficiency & Intensification of Pulp Paper Packaging & Tissue Manufacturing

J. Carson Meredith

Professor, School of Chemical and Biomolecular Engineering, Executive Director of the Renewable Bioproducts Institute

Email: [email protected]

Rallming Yang

Research Scientist II, Renewable Bioproducts Institute

Email: [email protected]

This website uses cookies. For more information, review our Privacy & Legal Notice Questions? Please email [email protected]. More Info Decline --> Accept

‘Origami organs’ can potentially regenerate tissues

- Feinberg School of Medicine

CHICAGO - Northwestern Medicine scientists and engineers have invented a range of bioactive “tissue papers” made of materials derived from organs that are thin and flexible enough to even fold into an origami bird. The new biomaterials can potentially be used to support natural hormone production in young cancer patients and aid wound healing.

The tissue papers are made from structural proteins excreted by cells that give organs their form and structure. The proteins are combined with a polymer to make the material pliable.

In the study, individual types of tissue papers were made from ovarian, uterine, kidney, liver, muscle or heart proteins obtained by processing pig and cow organs. Each tissue paper had specific cellular properties of the organ from which it was made.

The article describing the tissue paper and its function was published Aug. 7 in the journal Advanced Functional Materials.

“This new class of biomaterials has potential for tissue engineering and regenerative medicine as well as drug discovery and therapeutics,” corresponding author Ramille Shah said. “It’s versatile and surgically friendly.”

Shah is an assistant professor of surgery at the Feinberg School of Medicine and an assistant professor of materials science and engineering at McCormick School of Engineering. She also is a member of the Simpson Querrey Institute for BioNanotechnology.

For wound healing, Shah thinks the tissue paper could provide support and the cell signaling needed to help regenerate tissue to prevent scarring and accelerate healing.

The tissue papers are made from natural organs or tissues. The cells are removed, leaving the natural structural proteins – known as the extracellular matrix – that then are dried into a powder and processed into the tissue papers. Each type of paper contains residual biochemicals and protein architecture from its original organ that can stimulate cells to behave in a certain way.

In the lab of reproductive scientist Teresa Woodruff, the tissue paper made from a bovine ovary was used to grow ovarian follicles when they were cultured in vitro. The follicles (eggs and hormone-producing cells) grown on the tissue paper produced hormones necessary for proper function and maturation.

It is really amazing that meat and animal by-products like a kidney, liver, heart and uterus can be transformed into paper-like biomaterials … . I’ll never look at a steak or pork tenderloin the same way again. ”

“This could provide another option to restore normal hormone function to young cancer patients who often lose their hormone function as a result of chemotherapy and radiation,” Woodruff, a study coauthor, said.

A strip of the ovarian paper with the follicles could be implanted under the arm to restore hormone production for cancer patients or even women in menopause.

Woodruff is the director of the Oncofertility Consortium and the Thomas J. Watkins Memorial Professor of Obstetrics and Gynecology at Feinberg.

In addition, the tissue paper made from various organs separately supported the growth of adult human stem cells. Scientists placed human bone marrow stem cells on the tissue paper, and all the stem cells attached and multiplied over four weeks.

"That’s a good sign that the paper supports human stem cell growth,” said first author Adam Jakus, who developed the tissue papers. “It’s an indicator that once we start using tissue paper in animal models it will be biocompatible.”

The tissue papers feel and behave much like standard office paper when they are dry, Jakus said. Jakus simply stacks them in a refrigerator or a freezer. He even playfully folded them into an origami bird.

“Even when wet, the tissue papers maintain their mechanical properties and can be rolled, folded, cut and sutured to tissue,” he said.

Jakus was a Hartwell postdoctoral fellow in Shah’s lab for the study and is now chief technology officer and cofounder of the startup company Dimension Inx, LLC, which was also cofounded by Shah. The company will develop, produce and sell 3-D printable materials primarily for medical applications. The Intellectual Property is owned by Northwestern University and will be licensed to Dimension Inx.

An Accidental Spill Sparked Invention

An accidental spill of 3-D printing ink in Shah’s lab by Jakus sparked the invention of the tissue paper. Jakus was attempting to make a 3-D printable ovary ink similar to the other 3-D printable materials he previously developed to repair and regenerate bone, muscle and nerve tissue. When he went to wipe up the spill, the ovary ink had already formed a dry sheet.

“When I tried to pick it up, it felt strong,” Jakus said. “I knew right then I could make large amounts of bioactive materials from other organs. The light bulb went on in my head. I could do this with other organs.”

“It is really amazing that meat and animal by-products like a kidney, liver, heart and uterus can be transformed into paper-like biomaterials that can potentially regenerate and restore function to tissues and organs,” Jakus said. “I’ll never look at a steak or pork tenderloin the same way again.”

Monica Laronda, who was a postdoctoral fellow in Woodruff’s lab during the study, also is a coauthor. She is now an assistant professor of pediatrics at Feinberg and a researcher at the Stanley Manne Children’s Research Institute, Ann & Robert H Lurie Children's Hospital of Chicago. Laronda and Woodruff also are members of the Robert H. Lurie Comprehensive Cancer Center of Northwestern University.

The research was supported by grant P50 HD076188-02 from the Center for Reproductive Health After Disease of the National Centers for Translational Research in Reproduction and Infertility, Google and the Hartwell Foundation.

Editor’s Picks

Deering Library undergoing major renovations

Northwestern celebrates the groundbreaking of new ryan field, forget imitation crab — researchers test snackable snails, related stories.

The childhood of Hans Christian Andersen explored in musical at Northwestern University

Northwestern academy supports evanston students, trethewey named to the academy of american poets.

Focus variation technology as a tool for tissue surface characterization

- Original Research

- Open access

- Published: 28 May 2021

- Volume 28 , pages 6813–6827, ( 2021 )

Cite this article

You have full access to this open access article

- Jürgen Reitbauer 1 ,

- Franz Harrer 2 ,

- Rene Eckhart ORCID: orcid.org/0000-0002-8095-4896 1 &

- Wolfgang Bauer 1

1755 Accesses

9 Citations

Explore all metrics

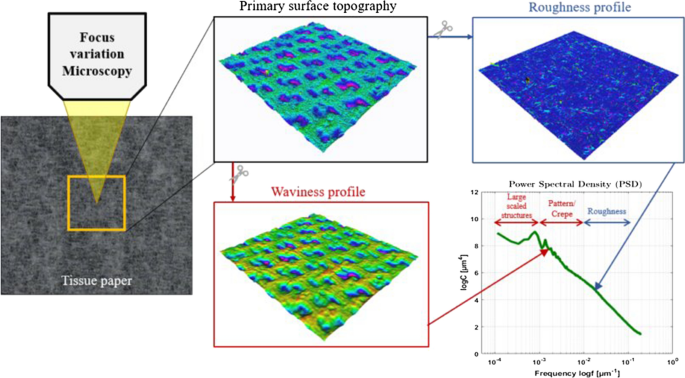

The surface of tissue paper is relatively complex compared to other paper grades and consists of several overlapping structures like protruding fibres, crepe and fabric-based patterns at different spatial frequencies. The knowledge of tissue surface characteristics is crucial when it comes to improvement with respect to surface softness and the perceptual handfeel of tissue products. In this work we used the optical based, non-contact measurement principle of focus variation for surface characterization of dry-creped, textured and through air dried (TAD) tissue. Based on the three tissue grades, a procedure which includes the characterization of the whole tissue surface throughout different scales within one setup, was developed. Surprisingly, focus variation was rarely used in tissue-related research, as it provides robust and reliable 3D surface information which can be used for further areal surface analysis. Special attention was given to the preparation and discussion of the raw data up to the final analysis including several spatial filtering steps. Enhanced surface parameters like the developed interfacial area ratio (Sdr) and the power spectral density (PSD) were used to describe the surface adequately. The surface roughness of the three tissue grades was compared, with the textured tissue showing the highest roughness in Sdr and PSD analysis. Although both methods are based on different principles, a high correlation in terms of evaluated roughness is evident. Regular structures like crepe and patterns are obtainable as peaks at the respective frequency with a certain intensity in the PSD evaluation. Apart from topography in terms of structures and roughness, the wide field of view of the focus variation measurement also allows assessment of effects related to flocculation and sheet formation. The developed procedure could also be appropriate for other fibre based materials and/or fabrics, which are similar to tissue with respect to optical properties such as for example nonwovens.

Graphic abstract

Similar content being viewed by others

Surface analysis of tissue paper using laser scanning confocal microscopy and micro-computed topography

Optical 3D crepe reconstruction for industrial base tissue paper characterization

Waviness analysis of glossy surfaces based on deformation of a light source reflection

Avoid common mistakes on your manuscript.

Introduction

In contrast to other paper grades, tissue paper is often in intensive contact with the human skin, especially facial and toilet tissue. Besides the functionality, the subjective perception of the overall quality and the softness of the tissue plays a major role when it comes to a purchase decision of the costumer. de Assis et al. ( 2018 ) carried out comprehensive work on the importance of softness and classified it with other tissue properties like strength and absorbency. Tissue manufacturers are well aware of this fact and constantly strive to improve tissue quality regarding the softness and handfeel properties. Softness, however, depends on many physical properties which can be related either to a surface or bulk component (Hollmark 1983 ). When it comes to bulk softness, paper stiffness, respectively paper flexibility plays a major role and is assessed in various ways (Hollmark and Ampulski 2004 ; Ko et al. 2017 ; Park et al. 2019 ).

The other major component is tissue surface softness which is consequently depending on the structural surface characteristics. As already mentioned, the perception “soft” differs between each person, nevertheless panel tests are an accepted method to validate tissue samples regarding their softness and were frequently studied to evaluate various surface softness methods (Furman et al. 2010 ; Rosen et al. 2014 ). Due to the complexity of panel tests, instrumental measurements like the Emtec tissue softness analyser (TSA) would be preferable, yet a correlation to the panel tests is not always given (Wang et al. 2019 ). Independent from the analytical tool of softness evaluation, the surface structure and topography of the tissue affects the results.

The measurement techniques for tissue surface characterization can be classified in contact and non-contact methods. An early approach of tissue surface characterization based on a contact method was done by Kawabata ( 1980 ) and Rust et al. ( 1994 ) with mechanical stylus scanning. The principle of a mechanical stylus instrument is based on a line scan of the surface. Based on the obtained height profile further surface related parameters can be evaluated, nonetheless the measurement strongly depends on the type of the used stylus (Ko et al. 2019 ). Nowadays, especially the stylus based surface roughness and friction measurement device KES (Kawabata Evaluation System) from Kato-Tech is used frequently for surface roughness and softness characterization (Lee et al. 2017 ; Ko et al. 2019 ; de Assis et al. 2019 ). The main drawbacks of the contact surface evaluation are the direct impact of the stylus on the tissue surface and the only line based information of the height data.

By the use of non-contact methods the drawbacks of the stylus based methods can be avoided however, due to the optical measurement principle other problems occur, which are summarized and discussed for different devices elsewhere (Leach 2011 ). A comparison of different optical methods for the analysis of surface roughness on various papers grades was done by Mettänen and Hirn ( 2015 ). One big advantage of optical methods is the areal representation of the surface. Raunio et al. ( 2018 ) used the method of photometric stereo to characterize the 3D structure of belt creped tissue paper based on greyscale images. In another study from Raunio et al. ( 2012 ) an optical reflectance method was used to characterize the influences of basis weight variations on the crepe frequency. Rosen et al. ( 2014 ) studied topographic modelling of haptic properties of tissue with surface parameters gained by digital light projection. A different approach was used by Gigac ( 2019 ) who used photoclinometry (inclined illumination), to relate surface softness with optical surface variability. Confocal laser scanning microscopy (CLSM) is an often used and accurate method to characterize the 3D topography of the tissue surface. Furman et al. ( 2010 ) used the CLSM for surface characterization of different tissue types, and correlated one roughness parameter successfully with softness from a panel test. A detailed study of the crepe structure and its dependence on the crepe blade lifetime for dry-creped tissue was performed by Ismail et al. ( 2020 ) using a CLSM. They further linked the topographical data with surface softness and handfeel properties, nevertheless they did not use any areal surface parameter for evaluation.

Areal surface analysis is necessary for tissue, since compared to other paper products, tissue has a complex surface containing crepe and pattern structures with a low network density and protruding fibres. These factors strongly influence some common roughness parameters like Sq (root-mean-square based surface height) and Sa (arithmetic mean based surface height). Therefore an interpretation of these parameters is often not reasonable for very rough surfaces like tissue. An overview of the prevalent surface parameters and their underlying concepts is given by Leach ( 2013 ). The developed interfacial area ratio (Sdr) is an areal based surface parameter and describes the surface roughness of tissue satisfactorily. Furman et al. ( 2010 ) already used this parameter in their CLSM measurements successfully for the surface roughness evaluation of tissue paper. Still, this surface parameter was rarely used in related research. Another method to characterize the tissue surface is the power spectral density (PSD) discussed in detail by Jacobs.et al. ( 2017 ). Pawlak and Elhammoumi ( 2011 ) applied PSD analysis in tissue related research to evaluate the surface softness based on line data of a lateral cut.

The chosen optical method used in this work is an infinite focus measurement (IFM) device. The measurement is based on optical focus variation only, whereas CLSM uses an additional laser for topography evaluation, hence the investment costs for a CLSM are generally higher. The IFM is a robust and accurate optical method with high resolution. An overview of the technique and its application in various fields is presented by Danzl et al. ( 2011 ). In the field of paper industry the technology was rarely used. Lechthaler and Bauer ( 2006 ) compared standard paper roughness measurements for graphical papers with the surface roughness measured with the IFM device and correlated several surface parameters. The influence of different magnifications on the results of surface parameters of office paper using the focus variation technique and a multi-scale roughness evaluation was observed by Vernhes et al. ( 2008 ). One tissue paper related work was presented by Wanske et al. ( 2008 ) using the IFM for the investigation of surface roughness changes due to ultrasonic penetration however, only two height based surface parameters were used for characterization.

In this work the measurement with the IFM was performed at three different magnifications to determine structures like crepe, fabric based patterns and roughness of dry-creped, textured and TAD tissues. The measurement and subsequent preparation and processing steps like filtering of the 3D datasets are described in detail. Enhanced areal surface evaluation was done using Sdr and PSD as parameters. The high field of view of the IFM allows an additional assessment of formation attributed effects which is also briefly discussed. With the obtained knowledge of the surface characteristics at all frequencies, effects on the surface due to the production process can be recognized and optimized. The developed procedure and the resulting parameters enable a comprehensive approach regarding the handfeel respectively surface softness properties in future work. With the flexibility of areal surface analysis and the advantages of the IFM, regions of interests throughout the tissue surface can be investigated in detail, while the temporal effort is low. This work provides an insight into the use of focus variation technology for tissue surface characterization in a novel and effective way.

Materials and methods

For surface topography evaluation three different tissue grades were used. The values for the basis weight (EN ISO 12625-6) and caliper (EN ISO 12625-3) are given in Table 1 . All three tissue grades consist of a blend of softwood and hardwood kraft fibres. The production however, is based on different manufacturing technologies. The most common type is the dry-creped toilet tissue, where the surface structure is mostly determined by the dry-creping process at the Yankee cylinder. The TAD surface structure depends on the machine configuration but mainly on the structure of the applied TAD fabric. Textured tissue is based on a hybrid technology of TAD and dry-crepe machine concepts. The surface structure is, like TAD, predetermined by the type of fabric, nonetheless the dewatering processes are not comparable. These differences in dewatering technologies yields different properties regarding bulk and surface structure. The surface analysis was always performed on the Yankee side of the 1-ply tissue samples.

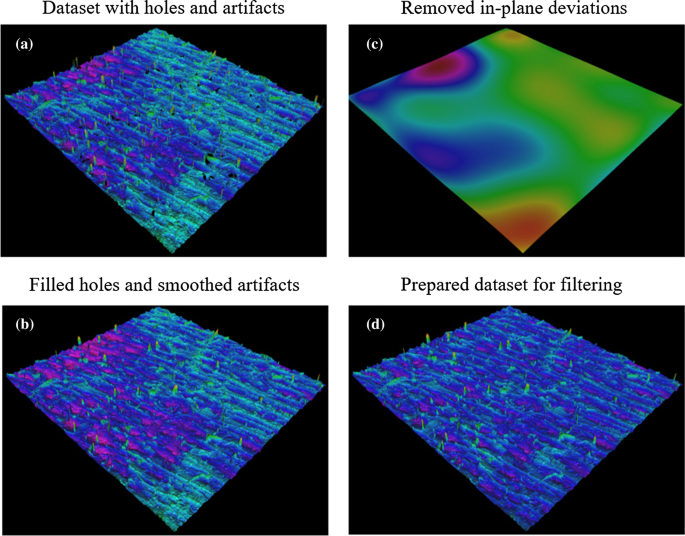

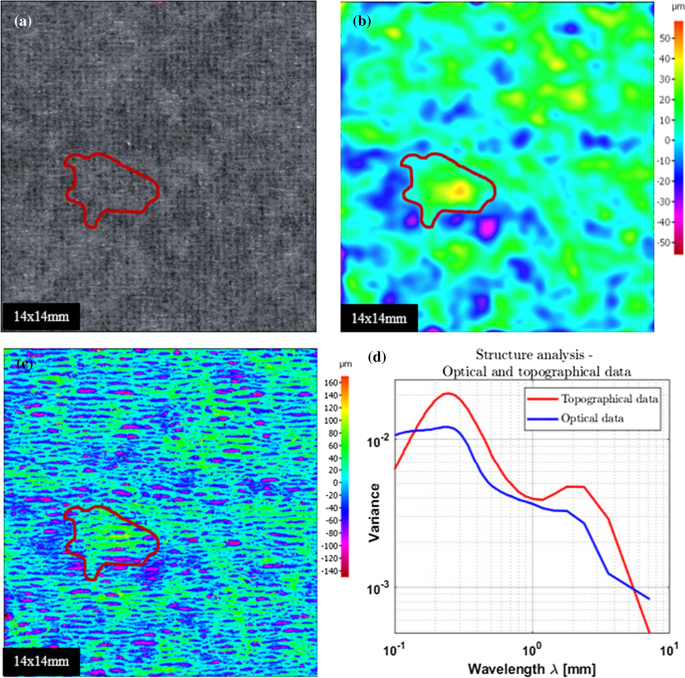

a Raw 3D dataset of the infinite focus measurement device containing errors like optical artefacts and missing data points due to the holes in the tissue network. b Corrected dataset with filled holes and smoothed artefacts. c Removal of large scale lateral plane deviations occurring during measurement d Dataset after preprocessing for further filtering including the automatically fitted reference plain (invisible)

Infinite focus measurement device

For the surface topography measurements an infinite focus measurement (IFM) device from Bruker-Alicona (Graz, Austria, Model G3) was used. The mode of operation of the IFM is based on detecting the best focus position of an optical element towards the tissue sample, which is related to a certain distance (Danzl et al. 2011 ). By repeating the procedure for many lateral positions, a 3D height map of the sample is generated. Besides the obtained 3D data the optical depth field color image of the surface is also acquired. The color image can subsequently be used to determine the optical formation based on Fourier analysis. An overview of the used magnifications and the respective resolutions is given in Table 2 . The same area is observed with three different magnifications (5x, 10x, 20x) to determine the various size-based structural patterns like roughness, crepe, fabric-based patterns and formation. For each magnification the vertical resolution depends on the size of the relevant structures (crepe, fabric, single fibres). The lateral dataset size takes into account the size of given structures, hence a certain periodicity is necessary for an accurate analysis.

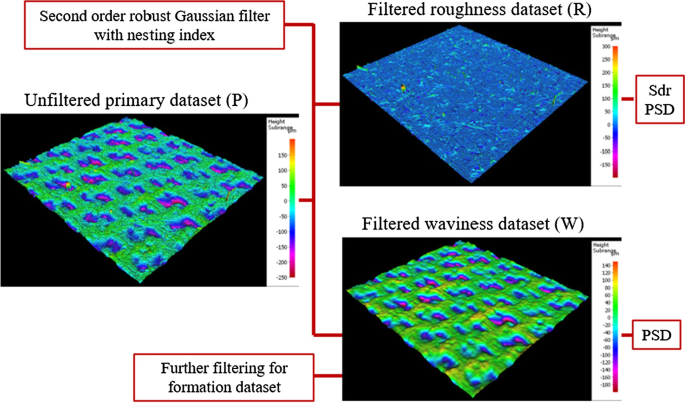

The preprocessed unfiltered primary dataset (P) is divided into a roughness and a waviness dataset by use of a second order robust Gaussian filter. The nesting index (cut-off wavelength) is \(80\ \mu \hbox {m}\) . The roughness dataset (R) contains information regarding the small scaled surface structures (smaller than the nesting index), while the waviness dataset (W) consists of the large scale structures. From both datasets, the PSD curve is evaluated, whereas the Sdr value is reasonable for the roughness dataset only. For the topographical variance analysis the waviness dataset (W) is further filtered to eliminate smaller structures (e.g. crepe)

Areal surface analysis

Preprocessing The areal surface analysis of the measured 3D datasets was carried out with the MeasureSuite 5.3.5. software from Bruker-Alicona. All of the necessary surface topography features like roughness, crepe and structures were extracted using this software according to a defined procedure, including three preparation steps (see Figure 1 ). First, the main errors and artefacts due to optical interferences and tissue irregularities (e.g. holes) in the measurement data have to be corrected. Measurement artefacts are visible as isolated steep 3D peaks and have a tremendous influence on areal surface analysis, hence they were removed with the application of a maximum flank-angle condition. Areal surface analysis depends on a continuous 3D dataset, therefore missing data points due to holes in the tissue have to be filled by interpolation between the nearest adjacent data points. It has to be noticed that such irregularities, despite the correction, always have a minor influence on the results of the areal surface analysis and cannot be completely avoided. The second step contains the elimination of the nominal form (e.g. in-plane deviations) with the use of a so called F-filter (Form-filter). During the measurement the tissue sheet is fixed with an adhesive tape to a black background paper (for optical reasons), thus small planar variances occur. The last preparation step includes the definition of a spatial reference plane, which is the base for all subsequent calculations.

Filtering Following the preprocessing of the 3D dataset, further filtering techniques are applied to obtain the required topographical information. Filtering is important for a proper surface characterization, since several common surface parameters like Sa, Sz and also the used Sdr could be erroneous due to superimposition of structural features. The effect of filtering on the Sdr is discussed in a further section in detail. The procedure from the preprocessed data to the final parameters is illustrated in Fig. 2 . Based on the preprocessed primary data (P), the roughness (R) and waviness (W) profile is separated with a cut-off wavelength of \(80\ \mu \hbox {m}\) , which is called nesting-index by Blateyron ( 2006 ). The applied nesting index of \(80\ \mu \hbox {m}\) is valid for all used tissue grades at all magnifications and is determined with an empirical approach specifically for the used dataset and measurement configuration. For the filtering process itself a second order robust Gaussian filter for arbitrary planes (ISO 16610-71) was used. The filter considers the edge effects of inclined, as well as curved planes and has a low sensitivity towards defects like outliers and holes. However, the computational effort is high.

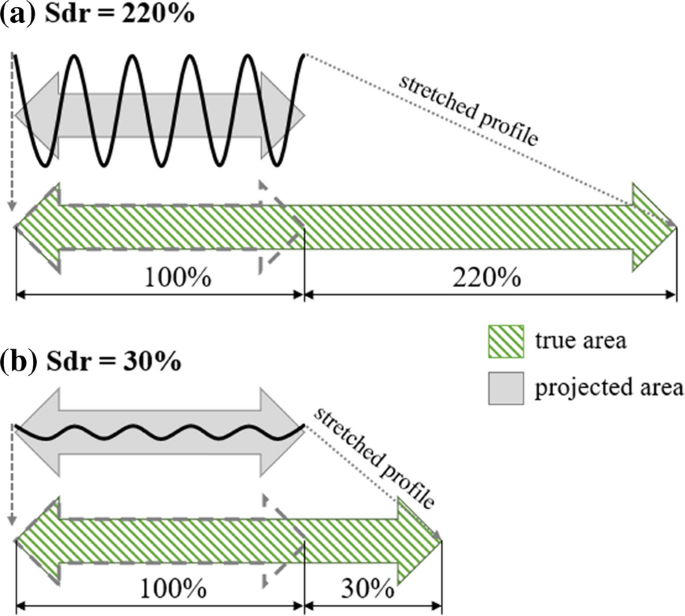

Developed interfacial area ratio (Sdr) The developed interfacial area ratio (Sdr) is used as one out of two parameters to describe small scale structures (i.e. roughness). The principle of the Sdr (ISO 25178) is shown in Fig. 3 and is used as a measure of the surface complexity i.e. roughness.

The developed interfacial area ratio (Sdr) is used as a parameter for roughness evaluation. It describes the difference between the developed (true) and the projected surface area in percent, which is shown exemplary. The higher the Sdr ( a ), the higher is the complexity and hence the roughness of the surface. (Redrawn from Bruker-Alicona ( 2019 ))

The Sdr describes the difference between the developed (true) and the projected surface area in percent (see Eq. 1 ), with a totally flat and smooth surface having a \(\hbox {Sdr} = 0\)

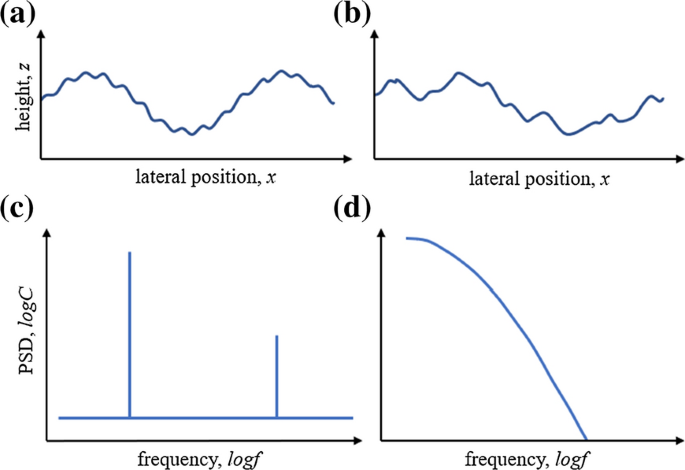

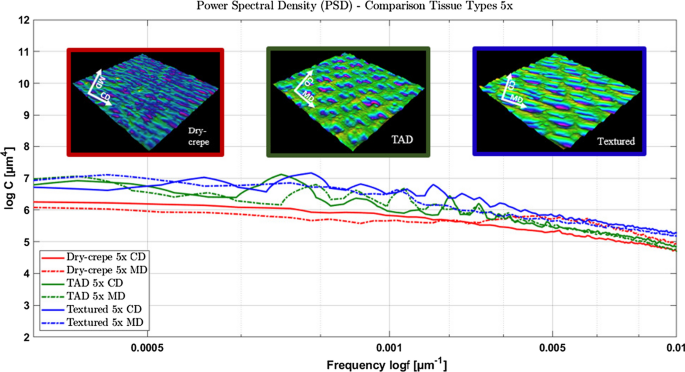

Power spectral density (PSD) In a comprehensive study Jacobs.et al. ( 2017 ) defined the power spectral density (PSD) as a tool to obtain the different spatial frequencies of a surface by Fourier transformation of the autocorrelation function signal. In surface topography analysis the PSD provides information on the appearance of periodic structures, like crepe and fabric patterns, which can be related to a certain spatial frequency range respectively structural size. These periodic structures are obtainable as peaks in the PSD curve. The surface roughness can also be determined and is defined by the height of the curve within the roughness frequency range. The peaks are summarized over the frequency range and are depicted as a distribution over all frequencies. When comparing the roughness of various tissue samples, differences in the height of the PSD curves occur. The higher the level of the PSD curve, the higher is the surface roughness and vice versa. For a 1D line profile the concept is explained schematically in Fig. 4 .

The power spectral density (PSD) curve is shown for two different 1D profiles, with the quadratic mean height being the same. Profile a consists of two overlapping sinus waves, while profile b contains several frequencies. The PSD curve c shows the two sinus waves from profile a as peaks (power spectral density logC) at different frequencies (logf). The PSD curve of an arbitrary profile as for b is shown in d . (Redrawn from Jacobs.et al. ( 2017 ))

In case of our work, the analysed surface data contains 3D structures, therefore the logarithmic power spectral density (logC) on y-axis changes to a power of four ( \(\mu m^{4}\) ) while the logarithmic spatial frequency on x-axis remains as \(\mu m^{-1}\) . For simplicity reasons the surface is represented by a 1D PSD curve as it is shown in Fig. 4 d. Due to the simplification and the anisotropic features of tissue a separate evaluation in machine direction (MD) and cross direction (CD) is necessary for the examination of structural properties like e.g. crepe or fabric patterns.

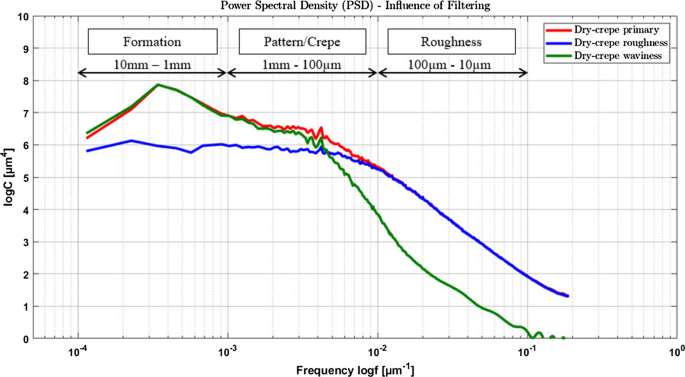

The spatial averaged PSD curves for the dry-creped tissue surface, which was acquired at a magnification of 10x, are shown separately for the primary and filtered waviness/roughness profile. A rough classification of the frequency spectra was done. The waviness PSD curve (green) follows and overlaps the primary PSD curve (red) in the lower frequency range, while the roughness PSD curve (blue) overlaps the primary PSD curve in the higher frequency range

For roughness related properties a combined and averaged PSD curve is suitable, as roughness features occur in all directions randomly. The maximum structural size that can be assessed depends on the field of view (see lateral dataset size in Table 2 ). The minimum structural size that can be reasonably assessed depends on the lateral pixel size, which is also listed in Table 2 for the specific magnifications.

Optical variance analysis

The field of view of the infinite focus device and the ability to acquire optical images simultaneously with the topography measurement allows optical variance analysis using a Fast-Fourier Transformation (FFT). The optical image from the lowest magnification (5x) is suitable to obtain optical variances at a scale of 2-5 mm. Image normalization and variance analysis based on the FFT algorithm were carried out in MATLAB (MathWorks, Massachusetts). The results are shown displayed as a variance distribution, where the unit-less logarithmic variance is plotted over the logarithmic wavelength \(\lambda\) (mm).

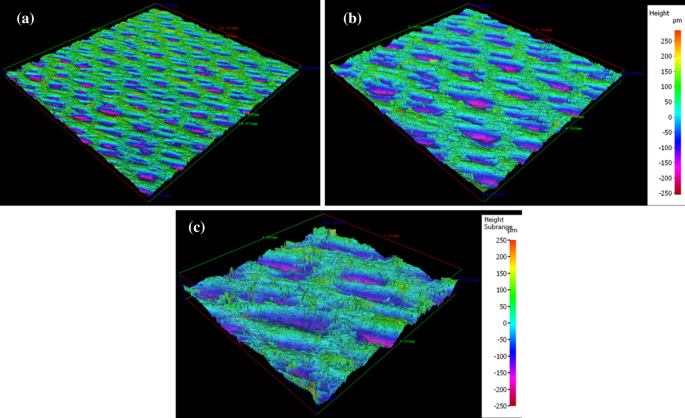

Surface of textured tissue observed with three magnifications. a Tissue surface at lowest magnification (5×) with a lateral size of 14 × 14 mm, which is used for structural and large scale analysis. b Medium magnification (10×) with a lateral size of 8 × 8 mm and is used for structural and roughness evaluation. c Highest magnification (20×) with a lateral size of 3.5 × 3.5 mm and is used for roughness evaluation

Results and discussion

Psd evaluation.

As already discussed (see Figure 2 ) roughness (R) and waviness (W) datasets were separated with the nesting index of 80 \(\mu \hbox {m}\) from the primary (P) dataset. By the use of this filtering technique, typical patterns and structures like e.g. crepe can be determined and described, as presented by Rosen et al. ( 2014 ). On the other hand the surface roughness is accessible for analysis without the underlying topographical structure that might affect the used roughness parameters. This allows for example the evaluation of the effect of the morphological characteristics of different fibre types on the surface roughness. While the PSD, as it is applied in this work, does not provide any numerical values like e.g. Sa, Sz or Sdr it does allow evaluation of the complete structural size spectrum of the given surface within one curve. Figure 5 shows the spatial averaged PSD curves for a dry-creped tissue surface, which was acquired at a magnification of 10x. In this figure the - in terms of direction - averaged PSD data is used for simplicity reasons. Still, when assessing structural properties, a detailed discussion in terms of MD and CD is necessary as it is shown below when comparing tissue grades. The diagram shows the PSD curve from the primary and also the incidental roughness and waviness data and gives an overview of the affected frequency ranges. The primary curve (red) includes all frequencies and has an overlap with the waviness curve (green) at lower frequencies (inverted x-axis), while the roughness curve (blue) has an overlap with the primary curve at higher frequencies.

As described in the “ Methods ” section, the surface roughness is characterized by the height of the PSD curve in the roughness range. Periodic structures like crepe or patterns from the fabric can be obtained as peaks in the curve. Such a dominant peak is, for example, visible in the averaged primary and waviness curve at a frequency of \(4*10^{-3} \mu \hbox {m}^{-1}\) which equals a structural size of \(250\ \mu \hbox {m}\) (40 crepes/cm). The crepe appears very regularly at this structure size. Deviations in the creping process, as observed by Ismail et al. ( 2020 ) due to blade wear, could be determined as peak shifts towards a higher or smaller frequency or to a less dominant and wider, or even to several small peaks. To detect possible effects attributed to formation in the PSD, the chosen magnification is only partly suitable as the lateral size is too small. This matter is discussed in the following section. In summary, the primary dataset contains the surface information within the whole frequency spectrum and thus shall be used for PSD analysis.

PSD—Effect of magnification

The level of detail of the obtained topographical data from the IFM depends on the vertical resolution of each magnification (see Table 2 ), thus the accessible surface information differs. The influence of the used magnification on the 3D surface data is shown exemplary for the textured tissue sample in Figure 6 . The benefit of the lowest magnification (5x) is the possibility to detect large sized structures and patterns while providing a certain periodicity. On the other hand, information regarding small scaled structures, like protruding fibres, is not available. This information can be provided at the highest magnification (20x), where small structures at fibre scale can be observed. Due to the optical measurement method protruding fibres are visible as long, steep flanked regions on the surface. Protruding fibres and also the contours of the fibre network mainly affect the roughness region of the PSD. An extended and valid overview of the frequency spectra is possible when all magnifications are considered. Surface roughness is of course represented more accurately at highest magnification while the medium and lowest magnifications are more precise at lower frequencies. For detailed analysis on surface roughness a magnification of 20x and for structural properties a magnification of 5x should be used.

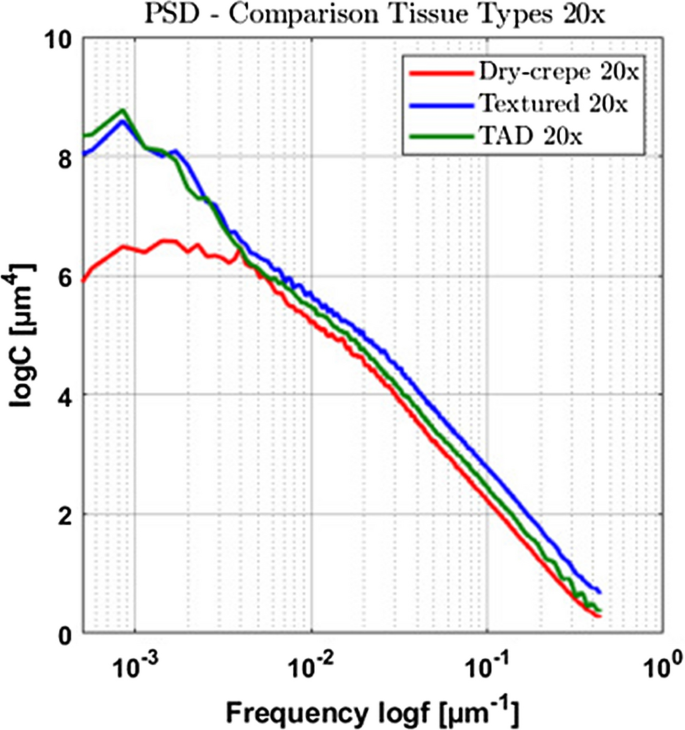

PSD evaluation—Comparison of tissue grades

Considering all discussed aspects of PSD and its application, the three used tissue grades are characterized regarding their surface properties. The corresponding primary PSD curves for roughness evaluation (20x) are shown in Figure 7 as spatially averaged PSD and for structural evaluation (5x) in Figure 8 as separate PSD curves for MD and CD.

Surface roughness analysis using spatial averaged PSD curves for the primary dataset of the three tissue grades at highest magnification (20×)

Separate primary PSD curves for MD and CD of the dry-creped (red), textured (blue) and TAD (green) tissue at a magnification of 5x. The corresponding surface topography is shown in a height map, framed with the color of the specific PSD curve

The surface roughness is examined in the frequency range from \(8*10^{-3}\) to \(2*10^{-1} \mu \hbox {m}^{-1}\) at the highest magnification (20x) for each tissue grade. Comparing the roughness PSD curves it is obvious that the textured tissue (blue) shows the highest values, hence the measured surface roughness is higher compared to the dry-creped (red) and TAD tissue (green). TAD shows slightly higher values for surface roughness than the dry-creped tissue. These differences may directly be related to the production process. The dry-creping step breaks the mechanical integrity of the network to some extent and therefore leads to fibres randomly protruding from the surface to create surface softness in standard dry creped products. TAD production excludes any mechanical compression and dewatering of the tissue web, which generates a looser network structure with a high roughness. Due to the structured surface of the TAD tissue, the contact area and hence the adhesion to the Yankee cylinder is reduced. The low adhesion between the Yankee and the tissue decreases the influence of the dry-creping step on the tissue surface and less fibres are protruding the network compared to other process configurations. In contrast to TAD, the textured tissue production process includes some mechanical dewatering, a wet-creping step and a dry-creping step, thus it combines the advantages of the TAD and dry-crepe technology regarding the surface structure (looser structure compared to standard dry crepe + protruding fibres due to extensive creping). In our case the increased amount of randomly protruding fibres are probably the reason for the textured tissues higher surface roughness compared to TAD.

For structural evaluation the PSD curves for the lowest magnification are illustrated in Fig. 8 separately for MD (continuous line) and CD (dash-dotted line). Additionally the filtered waviness height images of the three tissue grades are shown to provide context. Surface structure due to crepe and fabric patterns are visible in the range from \(5*10^{-4}\) to \(8*10^{-3} \mu \hbox {m}^{-1}\) . Differences between the MD and CD PSD curve of the dry-creped tissue are evident. The MD PSD curve shows a higher level as the CD PSD curve in the frequency range around \(5*10^{-3} \mu \hbox {m}^{-1}\) which is directly correlated to the periodical MD dry crepe structure. Compared to textured and TAD the dry-crepe PSD curves show a certain maximum horizontal level in the range from \(1*10^{-3}\) to \(4*10^{-3} \mu \hbox {m}^{-1}\) . The dry-creped structure is mainly affected by the crepe height and regularity (e.g. crepes/cm). The crepe height is low compared to the height of the patterns from the textured and TAD samples, which is also evident in the caliper values in Table 1 . Differences in the surface structure between the TAD and textured sample can be detected via the amount and intensity of the peaks in Fig. 8 . The textured tissue PSD curves are located above the curves of the TAD on average, which indicates a generally higher height deviance from the valley to the top of the patterns. In addition it shows several small peaks, which are related to various regular patterns in MD and CD with different heights and structural sizes. Especially in textured CD several peaks appear over a broad frequency range, which depend mainly on the used fabric. The PSD curves of the TAD sample show intense peaks, which appear at a broad frequency range in CD, while the peaks in MD are shifted to a lower frequency. These differences can be attributed to the molding process during the dewatering and the used fabric on the TAD tissue machine. The analysis and comparison of topography based PSD allows an enhanced view on the characteristics of tissue surfaces and provides a powerful tool for further optimization of tissue surface structures.

Structures for the topographical variance analysis can be obtained only at the lowest magnification (5x) due to the necessary lateral size. The variation in local mass is crucial in tissue production as it affects the creping and moulding process and thus the surface topography (see Raunio et al. ( 2012 )). The effect of large scaled structures on dry-creped tissue will be discussed separately.

Surface roughness evaluation with Sdr

Compared to the roughness evaluation with the PSD curve, the developed interfacial area ratio (Sdr) expresses the surface roughness as a figure in percent based on a different principle of surface roughness characterization (see Fig. 3 ). As it is common in surface analysis to describe and compare surface roughness with a numerical parameter, the Sdr is very suitable for tissue paper. In Table 3 the mean Sdr values for the magnification of 20x are listed. The Sdr values were evaluated for the primary (P), roughness (R) and waviness (W) profile, which are separated by a Gaussian filter (see Fig. 2 ). For each tissue grade three arbitrary areas were observed and the results were averaged. The corresponding standard deviations (SD) for each measurement are also shown in Table 3 and indicate a high reproducibility. Advantageously, the Sdr is nearly independent from textures and patterns on the surface (low Sdr (W) values), thus allowing the comparison of different tissue grades regarding their surface roughness. In contrary to Sdr, height based values like Sa or Sq have their limits in comparing tissue with deviations in caliper and structural patterns and should be avoided for characterization of such complex surfaces. Since structures have only a minor influence on Sdr analysis the difference between Sdr (P) representing the unfiltered topography and Sdr (R) representing solely the roughness profile is hardly significant. This shows that the interfacial area ratio (Sdr) does allow roughness measurement on tissue surfaces without pretreatment of the primary profile. Comparing the samples the textured tissue shows by far the highest Sdr, followed by the TAD and the dry-creped tissue which is in accordance with the results from PSD analysis (see Fig. 7 ).

a Greyscale image of the obtained tissue surface at a magnification of 5x. b Corresponding twice filtered topographical height map without the crepe structure. c Height map of the primary data. d FFT based structure analysis of the optical and topographical data

Optical and topographical variance analysis

The IFM provides a large field of view at lowest magnification (5x). This allows in addition to the described analysis of surface structures and roughness an optical and also a topographical analysis of large-scaled structures. Large structures in topographical variance analysis are identified by repetitive use of the Gaussian filter on the waviness dataset of the lowest magnification (5x) to eliminate smaller structures (e.g. crepe, fabric). In Fig. 9 the optical greyscale image (a), the corresponding filtered topographical height map (without the crepe-structure) (b) and the primary surface height map (c) for the dry-creped tissue are shown. In the primary height map (c) the crepe is visible as the dominant structure, with the frequency of the crepe varying throughout certain regions (such as in the region marked in red). It does seem that the crepe frequency is somewhat related to the underlying structure. The kind of relation would have to be clarified in future work. The inhomogeneity in the underlying structure of the paper is accessible with focus variation as is shown in the height map (b) and could have different reasons like e.g. formation effects in the wet end of the tissue machine or in-plane deviations due to the drying process. In the optical greyscale image (a) similar large scale variations are visible due to differences in light reflectance. This similarity in structures of the topographical and optical data is shown in the structure analysis in (d). In this analysis the primary topography image (c) was converted to a greyscale image and both, the optical and topographical image, were subsequently normalized and subjected to FFT based structure analysis. Beside the peaks at a wavelength of \(2.5*10^{-1}\ \hbox {mm}\) (which represent the crepe), there is an increase in variance for both datasets at a wavelength of 2 mm. This indicates a coherence between the optical grey scale image and topographical data that may be related to e.g. formation. Still, further work regarding topographical and optical large scale structure analysis and the reasosn for its coherence is necessary.

Conclusion and outlook

With the used infinite focus technology enhanced analysis of complex tissue surfaces is possible. The applicability can be extended to several fibre based materials with similar optical properties as tissue paper such as e.g. nonwovens. The optical method in combination with the developed procedure is fast, flexible, error robust and has a high capability compared to other surface measurement devices. The measured 3D datasets, consisting of a dry-creped, a textured and a TAD tissue sample are pre-treated to minimize optical errors for further assessment. The areal surface analysis considers the whole measured area and provides special parameters for surface evaluation. The power spectral density (PSD) is an appropriate tool to evaluate the whole frequency spectra of surface structures like crepe, fabric-based patterns and roughness simultaneously. The use of different magnifications extends the valid frequency range of the PSD curve, thus wavelengths from \(10\ \mu \hbox {m}\) up to 10 mm can be evaluated. Dominant structures are apparent as peaks and can be related to a certain wavelength. Changes in process conditions can be determined by a shift of the intensity and frequency of these peaks. Additionally to PSD evaluation surface roughness can be described with the developed surface area ratio (Sdr). PSD and Sdr are based on different concepts, although they show similar results regarding surface roughness and should be used primarily for complex surfaces like tissue. Both parameters can be considered as a potential measure to describe handfeel related properties like tissue surface softness in future work. Due to the high field of view of the infinite focus device and the possibility to obtain optical images, the method is also suitable to evaluate the optical variations in combination to the topographical information. Summming up, this work shows the potential of optical based tissue surface analysis by means of focus variation. Such a detailed surface analysis is crucial for a better understanding of tissue surface and human skin interactions.

Availability of data and materials

The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

Code availability

Commercial software was used.

Blateyron F (2006) New 3D parameters and filtration techniques for surface metrology. In: JSPE, pp 1–7