- Data, AI, & Machine Learning

- Managing Technology

- Social Responsibility

- Workplace, Teams, & Culture

- AI & Machine Learning

- Diversity & Inclusion

- Big ideas Research Projects

- Artificial Intelligence and Business Strategy

- Responsible AI

- Future of the Workforce

- Future of Leadership

- All Research Projects

- AI in Action

- Most Popular

- The Truth Behind the Nursing Crisis

- Work/23: The Big Shift

- Coaching for the Future-Forward Leader

- Measuring Culture

The spring 2024 issue’s special report looks at how to take advantage of market opportunities in the digital space, and provides advice on building culture and friendships at work; maximizing the benefits of LLMs, corporate venture capital initiatives, and innovation contests; and scaling automation and digital health platform.

- Past Issues

- Upcoming Events

- Video Archive

- Me, Myself, and AI

- Three Big Points

How Puritan-Bennett Used the House of Quality

In 1988, Don Clausing and I wrote an article on the “House of Quality,” a product development technique that had long been used in Japan and that was gaining popularity in the United States. 1 Since then, over a hundred U.S. firms have adopted the technique for part or all of their product development activities. The House of Quality method, which is a part of Quality Function Deployment (QFD), has evolved through use. The formal charting techniques have given way to sophisticated market measurement, and firms have modified QFD to work within their corporate cultures.

The following case study illustrates how one company successfully used the House of Quality and QFD to enhance sales and profit while satisfying customers and reducing the cycle time of new product development. This case is rare because the company has agreed to share all the details of the application and the business implications.

The paper begins with a brief overview of the House of Quality concept. Then I describe the case study, and, to help readers understand the application of the method to a wide variety of markets, I close the paper with eight brief examples of other applications.

The House of Quality

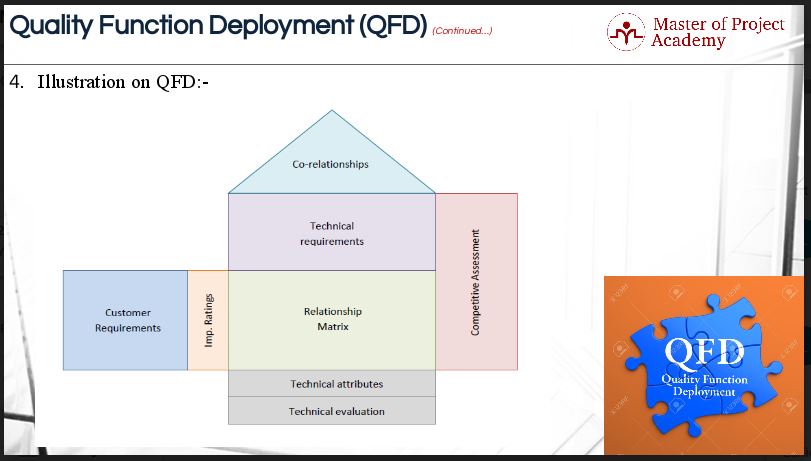

Mitsubishi’s Kobe shipyard developed quality function deployment in 1972. Ford and Xerox brought it to the United States in 1986, and, in the last five years, it has been adopted widely by Japanese, U.S., and European firms. In some applications, it has reduced design time by 40 percent and design costs by 60 percent while maintaining and enhancing design quality. 2 QFD helps an interfunctional team of people from marketing, research and development (R&D), manufacturing, and sales work together to focus on product development. It provides procedures and processes to enhance communication by focusing on the language of the customer. 3

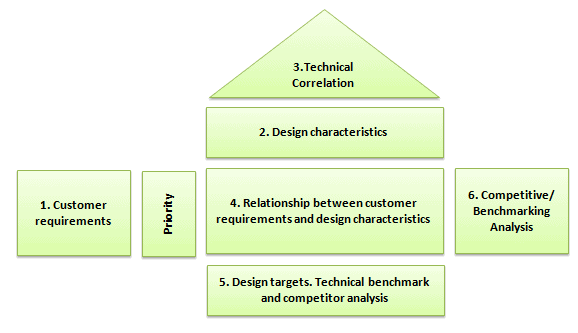

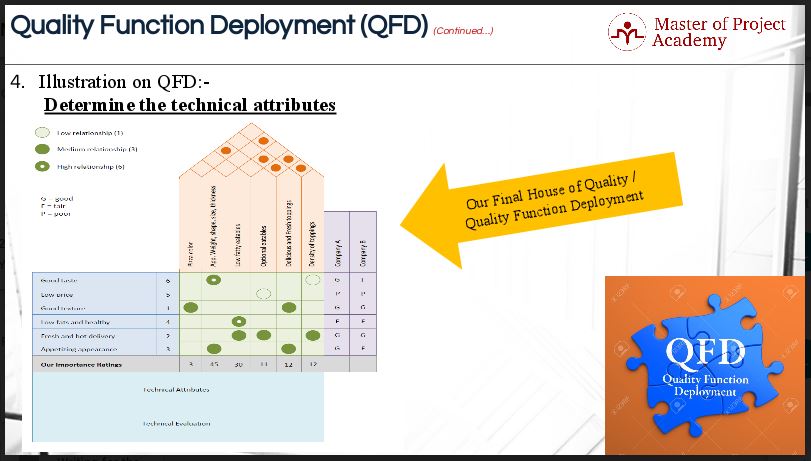

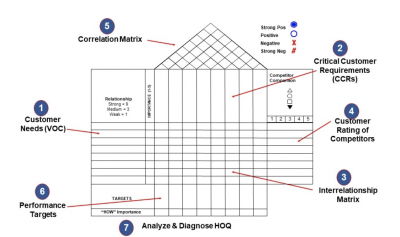

QFD uses four “houses” to integrate informational needs. Applications begin with the House of Quality (HOQ), which is shown conceptually in Figure 1 . The team uses the HOQ to understand the voice of the customer and to translate it into the voice of the engineer. Subsequent houses continue to deploy the voice of the customer through to parts characteristics, key process operations, and production requirements.

The Voice of the Customer

Identifying customer needs., about the author.

John R. Hauser is the Kirin Professor of Marketing at the MIT Sloan School of Management.

1. J.R. Hauser and D.P. Clausing, “The House of Quality,” Harvard Business Review , May-June 1988, pp. 63–73.

3. For a head-to-head comparison of communications patterns in an HOQ process with those in a traditional phase review process, see:

A. Griffin and J.R. Hauser, “Patterns of Communication among Marketing, Engineering, and Manufacturing — A Comparison between Two New Product Teams,” Management Science 38 (1992): 360–371.

For a scientific examination of different methods to identify the voice of the customer, see:

J.R. Hauser and A. Griffin, “The Voice of the Customer,” Marketing Science 12 (1993): 1–25.

4. For a comparison of methods, see:

Griffin and Hauser (1993), ibid.

5. The customer incurs no out-of-pocket cost. PB dispatches a new unit the same day and pays all shipping costs to and from the customer. The customer need only place the old unit in the box in which the new unit was shipped, affix an enclosed label, and call. PB arranges for pickup. In other words, the customer service programs were also based on the identified customer needs.

More Like This

Add a comment cancel reply.

You must sign in to post a comment. First time here? Sign up for a free account : Comment on articles and get access to many more articles.

Six Sigma Study Guide

Study notes and guides for Six Sigma certification tests

Quality Function Deployment (QFD) and House of Quality (HOQ)

Posted by Ted Hessing

Quality Function Deployment (QFD) and House of Quality (HOQ) are structured approaches for defining customer requirements and translating design specifications and product control characteristics into a planning matrix. In other words, using QFD allows the charting of customer wants and technical hows, which results in a better understanding of design relationships.

Quality Function Deployment (QFD) and House of Quality (HOQ) is a planning process for products and services that starts with the voice of the customer. Basically, it enables people to think together. You can also include a competitive analysis. People on your team will be better aligned and able to think together toward a solution.

Why Use Quality Function Deployment?

- Effectively communicate customer requirements and strategically prioritize efforts throughout the organization.

- Is a customer-driven process for planning products and services.

- Helps to identify important parameters to include in the design.

- Allows you to compare the design parameters with competitive products.

- Reduces the development time and is cost-effective.

Importance of Quality Function Deployment ( QFD ) and House of Quality (HOQ)

Yoji Akao first developed Quality Function Deployment in Japan in 1966. QFD helps incorporate all the customer needs into the final product in the early stages of the design phase. Furthermore, it is a planning tool to determine the key areas in which the effort should focus in relation to our technical capabilities.

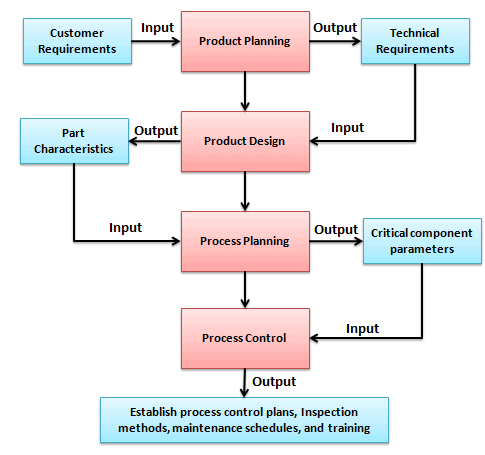

Four primary phases of QFD – Product development steps

Product planning:

- Identify customer requirements.

- Translate VOC into design specifications or product control characteristics as a planning matrix.

- Prioritize requirements.

- Evaluate competition and prioritize requirements.

Product design:

- Generate design ideas or concepts.

- Translate the outputs of the product planning phase into individual part details that define part characteristics.

- Identify product risks.

- Define the product specifications.

Process planning:

- Define the product development process and establish critical component parameters.

- Establish critical process controls.

- Create a manufacturing process flowchart and document process parameters (or target values).

Process control (production planning):

- Define the production requirements for each component/operation.

- Establish inspection and test methods.

- Define performance indicators to monitor the production process.

What is House of Quality (HOQ)?

A house of quality (HOQ) involves collecting and analyzing the “ voice of the customer ,” and it is a key part of the Quality Functional Deployment technique. It is used to define the relationship between customer desires and the product or company’s capabilities.

Step 1: Customer Requirements – “Voice of the Customer”

The first step in a HOQ is to determine the market segments and identify prospective customers. The team collects customer requirements and rates them on a scale of 1 to 5, with 5 being the most important and 1 being the least. Then they calculate the relative importance.

Step 2: Technical measures

Product requirements or technical characteristics are aligned with the voice of the customer. This step can be quite difficult as it involves people working in groups to skim out the variables that may affect the customer requirement factors the most. Parameters should be meaningful, measurable, and global.

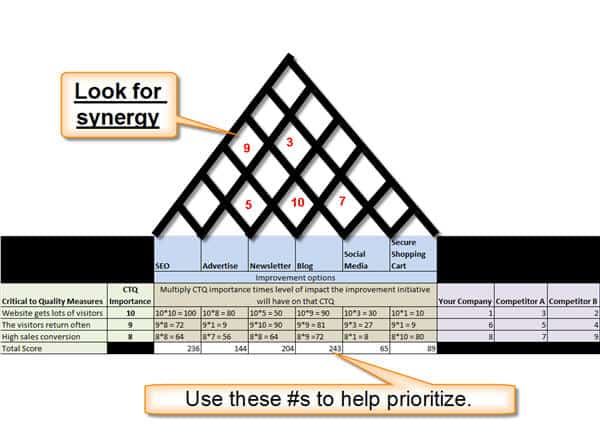

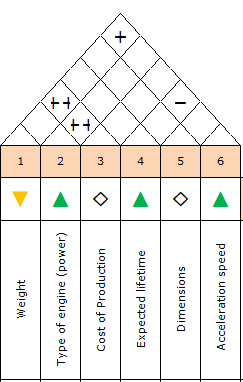

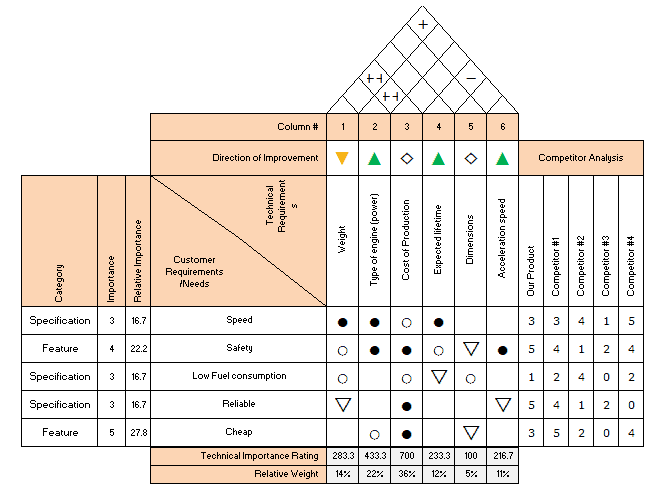

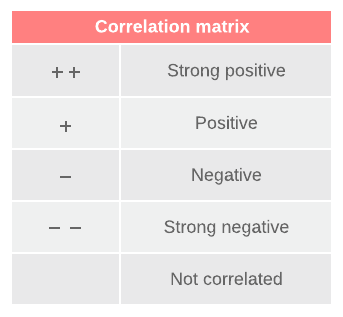

Step 3: Roof / Correlation Matrix

The triangular “roof” matrix of the House of Quality is to identify how the design requirements interact with each other. It helps the designers in the next phase of the QFD project. The triangular matrix looks like a house with a roof. The interrelations are rated strong positive as “+ +,” whereas strong negative as “- -“and blank for no interrelation.

Step 4: Relationship Matrix

Develop a correlation between customer requirements (or the voice of the customer) and the design characteristics or technical requirements. Decide the symbols you want to use to describe your desired grades. These should be consistent and easy to understand.

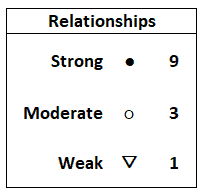

The ranking system use is a set of symbols for strong, medium, and weak relationships. Each of the symbols represents a value of 9 for strong, 3 for medium, and 1 for weak.

Step 5: Importance Rating

The Importance Rating is the result of calculating the total sum of each column when multiplied by the customer importance factor. It helps to determine where to assign the most resources. Then, calculate the percentage of importance.

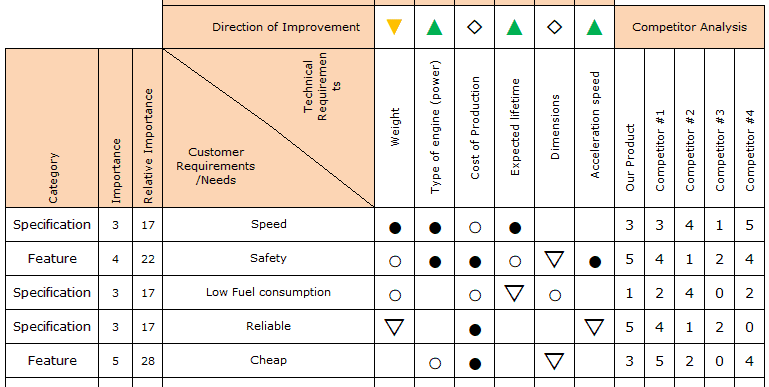

Step 6: Competitive Evaluation

Competitive Evaluation helps to understand competitor products that fulfill customer requirements. It is a good idea to ask customers how the product or service rates are in relation to the competition. Use surveys, customer meetings, or focus groups/clinics to obtain feedback. Measure the satisfaction on a scale of 1 to 5, where 1 is highly dissatisfied and 5 is highly satisfied.

Identify more specific target values for technical specifications to satisfy the VOC. This section helps appropriate teams within the origination to develop next-level QFD.

Example of House of Quality (HOQ)

Quality Function Deployment functions such as House of Quality are used on consumer products to identify and manage design trade-offs. It involves studying customer requirements, which can take many forms. For example, a marketing survey that has been targeted towards a certain marketing group is a way to study customer requirements.

It may not work well for existing products, but the results are quite efficient if you consider solving a big design problem. Usually, the purpose of this survey is to find out what the consumers want from the consumers. The House of Quality is a good patch between customer requirements and engineering variables.

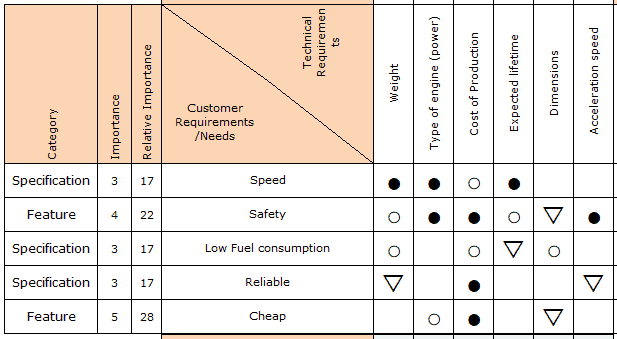

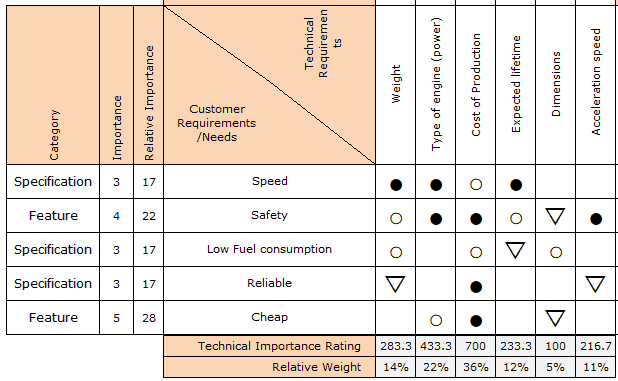

Example: We pick a car on which we are going to perform a house of quality analysis. Since this is a hypothetical scenario, we will assume all the data.

Step 1: Customer Requirements-“Voice of the Customer”

The first thing you need to decide on is the customer requirements.

For example, the minimum requirements for a car might be:

- Low Fuel Consumption

The next thing we do is assume the importance of each of these car characteristics, like what is important according to the customers.

For example, let us rate all of these on a scale of 1 to 5, with 5 being the most important and 1 being the least.

- Safety – 4

- Low Fuel Consumption- 3

- Reliable -3

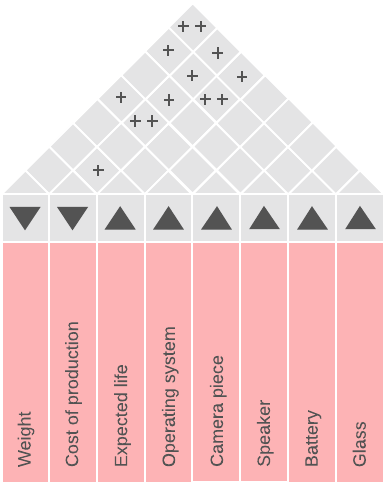

The next thing you need to do is figure out the engineering parameters that you need in order to design the car.

- Type of engine (power)

- Cost of production

- Expected lifetime

- Acceleration speed

It is also a good way to help establish the importance.

The first row is called up or down. In this column, you describe whether the following parameter is better with a high value or low.

For example, it is always better we have low weight, high engine power and life, low cost of production, high dimensions, and quick acceleration.

Similarly, you can now compare the effects of changing one alternative on the others. You can use symbols such as ++ to represent a strongly positive effect, + for a positive effect, 0 for no effect,– for a negative, and – – for a strongly negative effect.

Now fill in all the boxes of the design parameter columns. This is the largest and most difficult part of the design process.

The ranking system use is a set of symbols for strong, medium, and weak relationships. Also, each symbol represents a value of 9 for strong, 3 for medium, and 1 for weak.

E.g., rate how the weight is related to speed, fuel consumption, safety, size, reliability, and price. Do this for all the alternatives.

Sum up all of the values for each column of the engineering parameters and write the sum at the bottom of the table. This is the total importance of each individual engineering parameter.

Then calculate the percentage of importance: You add them up and then divide each importance value by the total to get the percentages. This will help you decide which parameters you need to focus on to meet the demands of the public.

It will also shed some light on the relative importance of each parameter in the design process.

Furthermore, you can use as many designs as you want and test as many alternatives as possible. It is all up to you! It all depends on the available data, the amount of detail you want to go into, and the extent to which you are willing to invest your time and resources in this process.

However, this process is very time-consuming if done manually, as many decisions must be made. Hence, you have to decide which factors are worth considering and which are not for one.

Use further add-ons to compare different alternatives in order to check how the different types of cars shape up with all the other alternatives.

Use a scale of 1 to 5, with 1 being highly dissatisfied and 5 being highly satisfied. For each customer requirement, rank 1 to 5 to the competitors and also for our product (car).

Also, use this add–on to check new designs that you make and learn to select the best optimization for anything you want to make.

This also helps identify discrepancies that you may have in your designs–know what you are lacking in your design that the public requires.

This is a good way to get everything in there at once. It is also suggested that you sign it as soon as you agree on something.

QFD Template Download

Unlock additional members-only content.

I originally created SixSigmaStudyGuide.com to help me prepare for my own Black belt exams. Overtime I've grown the site to help tens of thousands of Six Sigma belt candidates prepare for their Green Belt & Black Belt exams. Go here to learn how to pass your Six Sigma exam the 1st time through!

Comments (31)

How we can draw roof matrix. please give detail about roof matrix.

Abhay – I’ve added detailed videos. Hope this helps!

Update: We added step-by-step instructions via text and images above. Does this help?

what are the relationships between house of quality and quality function deployment

Good question. The House of Quality is sometimes referred to as a Quality Function Deployment Matrix. The House of Quality is the first chart used in Quality Function Deployment to design an improvement for a product or a service.

How to comment on portance weighting in qfd?

I am doing a DMADV project which is itself something new to the industry. I don’t have any data regarding this because it is proposed a modification in which I got 4 options. Out of these four options, I need to select one. I have customized house of quality in such a way that I became the customer because I know my desires and CTQs so, I built QFD of all four options. now I need to select one best option. Can I do it like this ???? What is the roof of QFD says?

Arlsan, can you share a picture?

Can I have a training schedule for the following: quality Technician

Sorry, Marcelleno. I do not currently offer training.

how is House of quality related to engineering?

Hi Tim, one way I would look at it is via my half-remembered IBM quote “There are no engineering solutions, there are only business solutions.”

By that I mean QFD and HOQ can help you prioritize what is built so that less waste occurs AND value delivered is maximized.

can i get house of quality example for specific product

I’ll add this request to the backlog, Wahi.

thank you sixsigmastudyguide for giving me wonderful information

Glad it helps, Rohit!

Is the interrelationship same with the roof of the HOQ?How are we going to build HOQ for cookies company whereby we have a voice of customer and technical features.How we gonna relate both VOC and technical featuree to create interrelationship and relationship matrix?

Can you share what you’ve tried here?

Construct a QFD house of quality diagram for Online/ blended education service provider of your choice (e.g. NPTEL, Swayam). How can this be done

Have you tried following the directions above? Can you share how far you’ve gotten?

Are there any other tools apart from QFD which can be used to translate the customer requirements into technical specifications?

And, what are the implications of the roof of Matrix, or the relationship of HOWs versus HOWs?

These sound suspiciously like homework questions.

You could use a CTQ tree to help translate customer requirements. I have no idea what you’re asking in the second question.

Hi, I have a question on weighting the CTS in HoQ #2. In HoQ #1 we weight the VoC by questioning the customer right? then do we have to do the same thing on the HoQ #2 to weight the CTS or could we just refer to certain value in the HoQ #1? Thank you

Hi Gede Keresnadi,

For HOQ#2, you’ll identify design requirements or technical measures for the product, such as weight, cost of production, and operating system. Once you identify the design requirements or technical measures, then you’ll identify how strongly each of the design parameters affects the customer’s need (step#4)– relationship matrix.

How does the House of Quality model apply to service provision, for example, the police service

Yes. HOQ can apply to any organization that has a strong client-centric focus.

Happy to coach you through. Can you list a few items that a police service clients’ might have strong desire for?

Thank you for this detailed article covering all the aspects

You’re welcome, Mashuk.

Thank you … you open my eyes in a new field

Welcome, Adele.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

Insert/edit link

Enter the destination URL

Or link to existing content

How to build a House of Quality (QFD)

Reading time: about 7 min

- Product development

- Professional development

Every product aims to fill a specific customer need, but pinpointing what customers actually need is more difficult than it seems. Without a clear understanding of the customer’s pain points, the development process can become bloated, misguided, or simply doomed from the start.

Quality function deployment (QFD) is a methodology created in response to this problem. It’s focused on providing a clear framework for addressing customer needs, beginning with a matrix called the House of Quality. Read on to learn more about QFD and how our House of Quality template can help you develop a product that resonates with customers.

What’s quality function deployment?

Understand customers.

Often, customers don’t even know what they want or need. The quality function deployment aims to understand customers better than they know themselves.

Predict how customers will perceive a product’s value

Understanding how customers will judge your product’s value is key throughout the entire development process. They may not see its value how you see it.

Obtain buy-in from stakeholders

All areas of the organization need to be informed about the customers’ needs so that they can create processes for developing, marketing, and selling to those needs.

Use customer needs to develop goals

Without determining performance goals, there’s no way to measure how well the product is fulfilling customer needs. Consider performance metrics (or “Critical to Quality” metrics aka CTQs), concepts, design characteristics, process parameters, and production controls.

Document requirements

This benefit should speak for itself: Without documenting the requirements, customer needs are simply a game of telephone that can be misinterpreted from department to department.

Provide structure

The front end of product development can become quickly mired in inefficiency. QFD provides logic and structure so development can take a deliberate approach.

Prioritize resources

QFD will allow you to pinpoint areas most critical to the customer and bottom line, then allocate resources properly to those areas.

As you can see, each aspect of the QFD is pointed toward the same “north star”—what your organization understands as your customers’ needs, based on feedback from surveys, focus groups, interviews, etc. Those customer needs are the directions your organization must follow to develop a successful product.

Phases of the QFD process

The entire QFD process is much more involved than we’ll get into in this article, but here are the basic steps:

- Product definition: This phase involves gathering VOC (through interviews, focus groups, and related methods) and determining how those customer requirements translate into product features or design requirements. The House of Quality fits into this stage. As you define the customer requirements, you’ll begin mapping them to your House of Quality template.

- Product development: During this phase, teams will translate the product specifications prioritized in the House of Quality into part and assembly characteristics and define functional requirements.

- Process development: During this phase, the company will design manufacturing and assembly processes to fulfill the House of Quality product specifications.

- Process quality control: Finally, those using the QFD process will identify critical characteristics and develop controls, inspections, and tests to ensure that those characteristics are met.

What is the House of Quality?

The QFD House of Quality is a voice of the customer analysis tool. Through multiple factors, including competitor research and the level of importance of each customer need, you can determine which product specifications take priority.

How to use the House of Quality template

Let’s walk through the process of putting together a House of Quality using a QFD example for a company building a new smartphone.

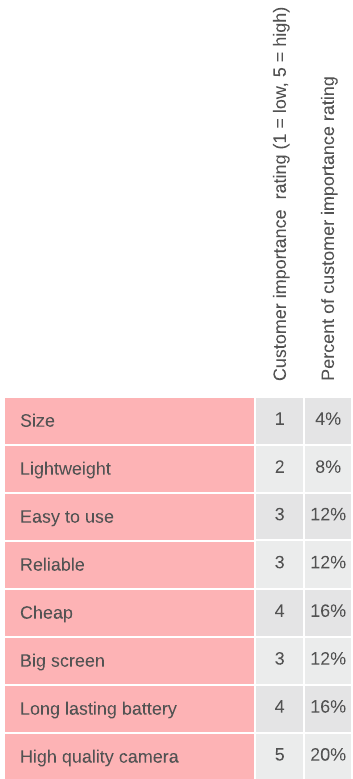

1. Add customer needs and ratings

On the left side of the House of Quality, you’ll enter the most important customer needs based on your research. For instance, in this House of Quality example, customers care about the following qualities when shopping for a smartphone:

- Easy to use

- Long-lasting battery

- High-quality camera

Next to the customer needs you have listed, rate how important each requirement is on a scale of 1 to 5. Customers may rate several traits of high importance, so it’s okay to have multiple 5s or multiple 4s. Ratings don’t have to be whole numbers either.

To the right, you’ll calculate the percent of customer importance rating for each requirement. Take the rating given to a requirement (1 to 5) divided by the total of all ratings.

2. List design requirements

Horizontally above the relationship matrix, you’ll add design requirements for the product, such as weight, cost of production, and operating system.

3. Weigh the relationship between customer needs and design requirements

In the relationship matrix, you’ll identify how strongly each of the design parameters affects the customer need. Use the following symbols:

As an example, if customers would like a less expensive smartphone, the cost of production will strongly contribute to the price. The operating system, battery, and glass used in the product will also affect the overall cost to customers, but not as strongly.

Once you have filled the relationship matrix, you can add the importance rating and percent of importance for each design requirement. To calculate the importance rating, multiply the percent of importance rating with the relationship score for each customer need. (In our House of Quality example, “size” has a 4% customer importance rating and a 9 relationship score, so the total would be 0.36.) Add those totals together for the importance rating.

After you calculate all the importance ratings, you can take each rating divided by the total for your percentages. The requirements with the highest importance ratings or percentages are likely the features that your company should prioritize or invest in more.

4. Complete the correlation matrix

The correlation matrix will determine how design requirements help and hinder each other.

Above each design requirement, you’ll mark whether it’s better for the feature to be lower (down arrow) or higher (up arrow). For example, it would be preferable for the weight of a smartphone to be lower, so the example includes a down arrow. On the other hand, it would be preferable for the battery to be higher (last longer), so the House of Quality example includes an up arrow. These ratings are up for interpretation.

Based on these up-and-down symbols, you’ll determine the correlation between different design requirements. Use the correlation matrix legend to designate these relationships using the appropriate symbol (placed in the square between two features).

For example, the operating system will greatly affect the expected life of the smartphone. Since both have up arrows, the two features have a strong positive correlation.

5. Add competitor research

Finally, the competitive assessment shows how companies currently rank for each of your customers’ needs so you can determine what has been overlooked and how you can gain an advantage over your competition.

The correlation matrix and competitor research do not affect the importance ratings, but they do provide additional insight to help you weigh which customer needs and design requirements matter most.

That’s it! Your QFD House of Quality is now complete. This will be your guiding matrix for determining what your product absolutely must have to appeal to your customers’ needs and wants. It will also be a useful tool in documenting the Voice of the Customer and keeping all processes on track throughout production.

Why do teams use QFD?

QFD and the House of Quality might seem like a lot of work, but QFD is a good option if any of the following apply to your business:

- Customer satisfaction is a main goal for your organization.

- There have been delays in development.

- There is poor interdepartmental communication about customer needs.

- Product and process decisions have not had clear guidelines.

- There is no clear, documented product definition.

- You are entering a new market.

- The product is not performing as well as it had been expected to.

- The product is becoming a commodity or people already view it as a commodity.

- You have more than one customer with differing needs.

Consider, too, that the longer it takes to develop a product and bring it to market, the more resources are invested in development. It is only a benefit to your organization to make the development process faster and more efficient.

Try filling out your own House of Quality template.

About Lucidchart

Lucidchart, a cloud-based intelligent diagramming application, is a core component of Lucid Software's Visual Collaboration Suite. This intuitive, cloud-based solution empowers teams to collaborate in real-time to build flowcharts, mockups, UML diagrams, customer journey maps, and more. Lucidchart propels teams forward to build the future faster. Lucid is proud to serve top businesses around the world, including customers such as Google, GE, and NBC Universal, and 99% of the Fortune 500. Lucid partners with industry leaders, including Google, Atlassian, and Microsoft. Since its founding, Lucid has received numerous awards for its products, business, and workplace culture. For more information, visit lucidchart.com.

Related articles

A quick guide on user story mapping.

Learn about user story mapping and how you can take advantage of user story maps to plan a more effective customer experience. Free templates included!

How to create a customer journey map

Customer journey maps are a powerful tool for understanding your customer's experience and adapting to meet their needs. Learn how to create a customer journey map (we even have free customer journey map templates available!).

Bring your bright ideas to life.

or continue with

By registering, you agree to our Terms of Service and you acknowledge that you have read and understand our Privacy Policy .

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

The House of Quality

- John R. Hauser

- Don Clausing

Design is a team effort, but how do marketing and engineering talk to each other?

Digital Equipment, Hewlett-Packard, AT&T, and ITT are getting started with it. Ford and General Motors use it—at Ford alone there are more than 50 applications. The “house of quality,” the basic design tool of the management approach known as quality function deployment (QFD), originated in 1972 at Mitsubishi’s Kobe shipyard site. Toyota and its suppliers then developed it in numerous ways. The house of quality has been used successfully by Japanese manufacturers of consumer electronics, home appliances, clothing, integrated circuits, synthetic rubber, construction equipment, and agricultural engines. Japanese designers use it for services like swimming schools and retail outlets and even for planning apartment layouts.

- JH John R. Hauser, at the Harvard Business School as a Marvin Bower fellow during the current academic year, is professor of management science at MIT’s Sloan School of Management. He is the author, with Glen L. Urban, of Design & Marketing of New Products (Prentice-Hall, 1980).

- DC Don Clausing , formerly of Xerox, is the Bernard M. Gordon Adjunct Professor of Engineering Innovation and Practice at MIT. He has edited Mr. Taguchi’s works in English and is a leading exponent of his views. He is the author (with John R. Hauser) of “The House of Quality” (HBR May–June 1988).

Partner Center

- Topical Articles =>

- PMP Certification

- CAPM Certification

- Agile Training

- Corporate Training

- Project Management Tools

Home / Six Sigma / 6 Steps to Build a House of Quality – Six Sigma Approach

6 Steps to Build a House of Quality – Six Sigma Approach

The QFD House of Quality, or Quality Function Deployment QFD , is a useful tool that Six Sigma Black Belt practitioners use during the Define phase of the DMAIC cycle of Six Sigma projects. The topic can be briefly discussed in Green Belt training or sometimes on online free Six Sigma courses . However, the House of Quality is one of the more advanced LEAN techniques .

Attend our 100% Online & Self-Paced Free Six Sigma Training .

- Do you want to know what is Power BI used for? Check out the new Power BI certification courses and learn how to use Power BI:

- Power BI Course Beginner

- Power BI Course Intermediate

House of Quality Steps

To build a house of quality, basic six steps are performed. House of Quality Steps are as follows:

- Identify what the customer wants .

- Identify how the product will satisfy customers . It refers to identifying specific product characteristics, features, or attributes and showing how they will satisfy customers

- Identify relationships between how’s . A couple of questions, that are to be answered here: How do our how’s tie together? What is the relationship between our two or more how’s?

- Develop importance ratings . It refers to using the customer’s importance ratings and weights from the relationships in the matrix to compute our importance ratings.

- Evaluate competing products or services . The question to be answered here is: How well do competing products meet customer wants? This activity is completely based on research.

- Determine the desirable technical attributes . In this step, our performance and the competitor’s performance are determined and compared.

The basic graphic diagram for any House of Quality looks like this.

How to Make a House of Quality? A House of Quality Example

Let us now begin with the actual process of generating a House of Quality for Pizza.

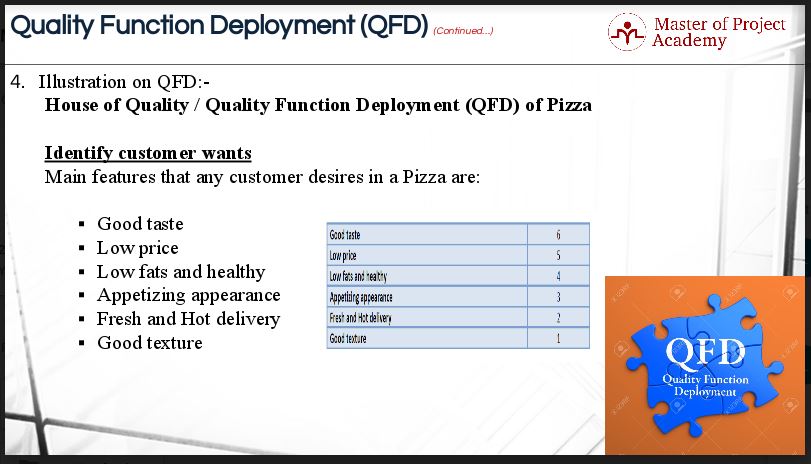

Identify what the customer wants

The main features that any customer desires in a pizza are:

- Low fat and healthy

- Appetizing appearance

- Fresh and hot delivery

- Good texture

To build a House of Quality we need to deep-dive into the main features . This part of building a House of Quality is normally a group exercise that requires brainstorming during product development.

- The first main feature is good taste. Taste is the first thing that a customer demands in any food item. The better the taste the more customers will demand it. So, it should taste fresh, hot, and spicy all the time .

- The second main feature is the low price. Price is the second most important factor according to the customers. The customer always tends to purchase food that tastes good at a low price. So, there shouldn’t be any compromise on taste while keeping the price as low as possible to meet the customer requirements.

- The third main feature is low fat and healthy. No one wants to get sick or become fat after eating something delicious. So, the pizza being sold to the customers should be low in fat and it should be part of a healthy diet for the customer. This is the key to winning the customer’s order.

- The fourth main feature is an appetizing appearance. The pizza should look mouthwatering . It should look delicious, appetizing, and spicy, even if the customer hasn’t yet tasted one.

- The fifth main feature is fresh and hot delivery. No one wants to have a stale pizza. Everyone wants a fresh and hot pizza, even if they’d ordered it home. Quick-n- Hot delivery should be maintained for all customers or else we’ll lose our customers.

- The sixth main feature is a good texture. Well, the texture is the lowest priority of customers. It is the same as the appearance of pizza but it is affected by the shape, size, method of baking, and ingredients too. Good texture for each variety of pizza should be maintained.

To build our House of Quality we have to determine the importance of ratings according to customer needs. We determine the importance ratings for our House of Quality on a scale of 1 to 6.

How will the product satisfy the customer’s wants?

In this step of building a House of Quality, we have to reflect the customer’s desires and demands in relation to our company’s product . For our House of Quality, we have to consider those before we finally approve the making and cooking of our Hot-n-Spicy pizza. Our product would be able to provide these features to the customer:

- Delicious and fresh toppings (sausages, meat, bread slices, etc.)

- Appropriate weight, size, shape, and thickness

- Low-fat eatables (less cheese and/or yeast)

- Optional eatables for taste and texture

Pizza color

- Variety and density of toppings

To build a House of Quality we need to deep-dive into these features one by one.

Fresh and delicious toppings

The first feature is Delicious and Fresh toppings. It is a key material for pizza. Delicious and fresh toppings would surely help customers’ winning orders.

Weight, size, thickness, and shape

The second feature is the appropriate weight, size, thickness, and shape. These features of pizza are directly related to pizza price. The heavier the pizza, the more it would cost, etc. So, the pizzas should be available in different sizes and weights so that every customer would be able to purchase the one that they prefer. That is why we’re going to introduce Medium and Large size pizzas.

Our customers want a healthy pizza. So, we’re going to use those ingredients which are low in fat. Some ingredients are essential for the taste of pizza but they have a high-fat value. Hence, we will try to use them as little as possible.

Optional eatables

Optional eatables are purely concerned with the taste and variety of pizzas. For providing great and delicious varieties in our pizzas, we will use different optional eatables to delight our customers. This factor is also concerned with price and texture.

For an appetizing appearance of a pizza, we would have to add some artificial colors to our pizza product. Additionally, these flavored colors also add spicy tastes to pizzas.

Density of toppings

The density of the topping is directly concerned with the thickness and price of a pizza. To provide varieties of pizza, we will use Low, Medium, and High density of toppings.

Developing the HOWs for our House of Quality

Now, in the next step of building our House of Quality we will develop the “HOWs” or how will our product satisfy our customers for our House of Quality. For this purpose, we will again develop a table displaying how this will satisfy them.

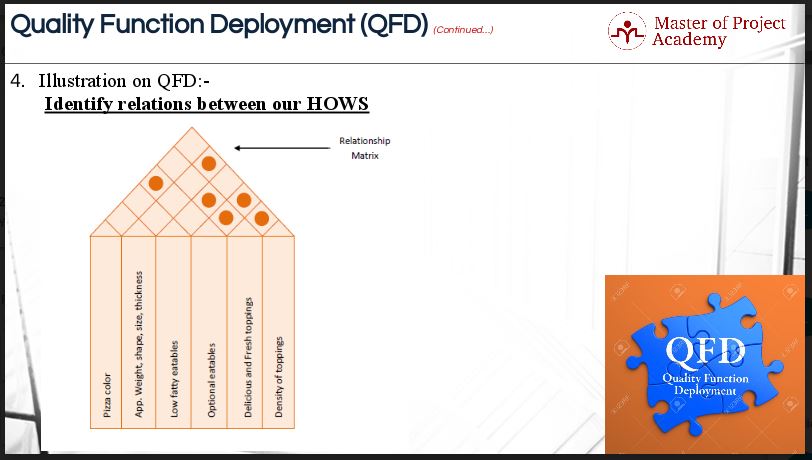

Identify relations between our HOWs for our House of Quality

In this step of building our House of Quality, we will develop a relationship matrix between our ‘HOWs’. For example, in many cases, some ‘HOWs’ are related to one another. Here’s a diagram showing an example of how HOWs can be related to each other when building our House of Quality.

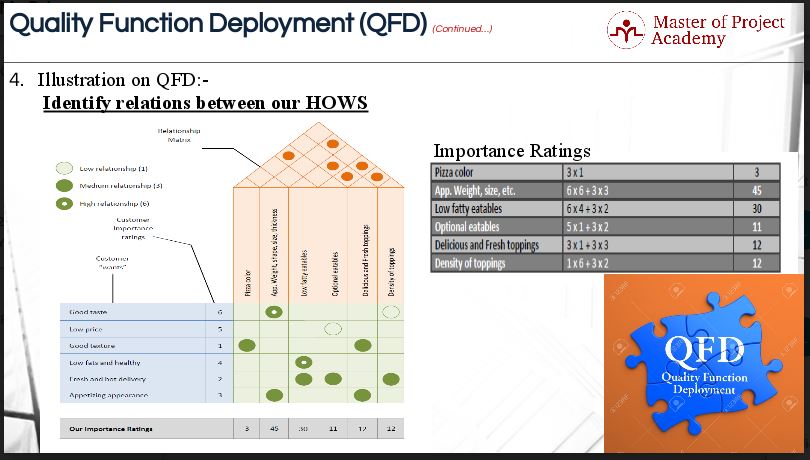

Develop importance ratings

This step of building a House of Quality is quite difficult and takes longer to complete. To build a House of Quality we will first draw the relationship matrix between the “HOWS” and the “WANTS” . Then, we will determine the importance ratings for our final work to be started.

Have a look at the diagram below. This step of building a House of Quality is shown here in a simplified and explanatory way. Let’s have a quick example to understand the table and how it is important for building our House of Quality.

The customer’s want for good texture has a medium relationship with pizza color. Good texture has an importance to the customer rating of 1. According to the grid in our diagram, the medium relationship i.e. the bold green circle has an importance rating of 3. So, simply multiply 3 by 1. That’s it! The answer for the importance rating of pizza color is 3.

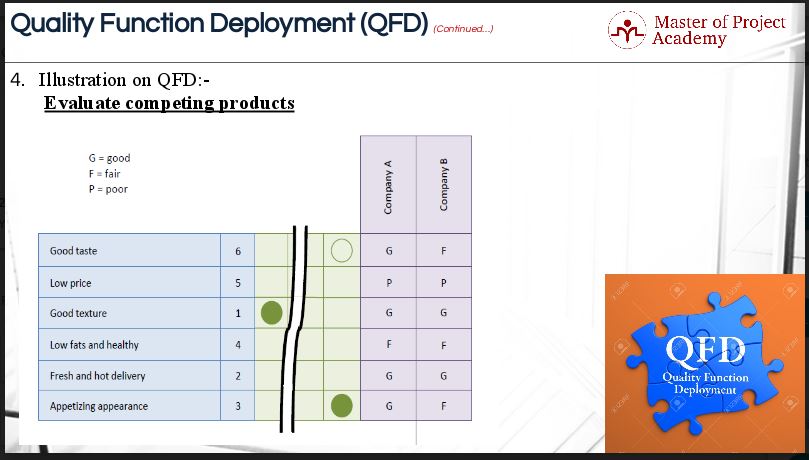

Evaluate competing products

In this step of building our House of Quality, we will compare the features of competing products of other companies . For example, two companies, Company A and Company B are competitors for our products. Hence, to build our House of Quality, we’ll first discuss and compare their pizzas to ours to get a more comprehensive and detailed report about our pizza.

Please have a look at the diagram below. On the left-hand side, we have customer wants. On the right-hand side, we’ve got Company A and Company B. According to our grid of G, F, and P, we have tried to evaluate our competitors’ pizza against customer wants.

Determine technical attributes

The last step in building a House of Quality is determining technical attributes and checking our performance with respect to market products .

And here is our final and full House of Quality or Quality Function Deployment (QFD) diagram for Pizza.

Good luck building your own House of Quality in the Define phase of your Six Sigma project. Use this LEAN tool to identify exactly how to produce a product that will delight your customers.

Related Posts

One thought on “ 6 steps to build a house of quality – six sigma approach ”.

- Pingback: 5 Must- know Snorkelling Tips for Beginners - Lesvos Adventure

Comments are closed.

Disclaimer:

- PMP, PMI, PMBOK, CAPM, ACP and PDU are registered marks of the Project Management Institute.

- ITIL® is a [registered] trade mark of AXELOS Limited, used under permission of AXELOS Limited. All rights reserved.

- PRINCE2® is a [registered] trade mark of AXELOS Limited, used under permission of AXELOS Limited. All rights reserved.

- Certified ScrumMaster® (CSM) and Certified Scrum Trainer® (CST) are registered trademarks of SCRUM ALLIANCE®

- Professional Scrum Master is a registered trademark of Scrum.org

- CISA® is a Registered Trade Mark of the Information Systems Audit and Control Association (ISACA) and the IT Governance Institute.

- CISSP® is a registered mark of The International Information Systems Security Certification Consortium ((ISC)2).

Master of Project Promo Codes PMP Articles

PMP Certification Ultimate Guide – 99.6% Pass Rate CAPM Articles

How it works

For Business

Join Mind Tools

Article • 12 min read

House of Quality Diagrams

Building customer satisfaction into new products.

By the Mind Tools Content Team

When you develop a new product, you need to make sure that it meets your customers' needs better than your competitors' products, however you also need to ensure that you can produce it economically, and that you're not asking impossible things from your design team.

This article describes a useful process for thinking about the targets you want to set for your product design team. The output of this process is a "House of Quality" diagram, and the process of drawing it is the process you use to set sensible design targets.

In this article, we'll describe the basic building blocks of a House of Quality diagram, and we'll show some simple examples.

Note, though, that while House of Quality diagrams can considerably improve product development, they can be baffling for the uninitiated: follow the steps below, and you'll understand the simple ideas that lie behind this seemingly complex approach!

About House of Quality

The "House" part of the name "House of Quality Diagrams" comes from the shape of the diagram, as we'll see later. "Quality" comes from the definition of quality that means delivering what customers' need reliably. (In the early days of quality improvement, changes were often made separately from one another, and objectives usually focused on reducing the rate of production defects or increasing product reliability. Later initiatives brought in the importance of meeting customer requirements.)

The first House of Quality was developed in 1972, when Mitsubishi Heavy Industries used it to help design an oil tanker. Since then, it's been used widely, and can be applied to services as well as to products.

Building Blocks

The House of Quality has six main sections:

- Customer Requirements – the starting point for the design process.

- Planning Matrix – information on how the market sees current offerings.

- Technical Requirements – a translation of customer requirements into in-house technical specifications.

- Interrelationship Matrix – a table showing how customer requirements affect individual technical specifications.

- Technical Correlations – these show possible compromises you may need to make, or opportunities you can take advantage of.

- Design Targets – the final output, defined using all of the information above.

These sections are laid out as shown in figure 1. (This arrangement should become clear as we work through the example within this article.)

Reprinted by permission of Harvard Business Review . From " The House of Quality " by John R. Hauser and Don Clausing, May 1988. Copyright © 1988 by the Harvard Business School Publishing Corporation; all rights reserved.

To illustrate how to set design targets using the House of Quality, we'll work through a simplified example of a company planning a new pen product.

The steps for building a House of Quality diagram are as follows:

- Determine customer requirements.

- Compare existing products and the planned products.

- Define the technical requirements.

- Create the interrelationship matrix.

- Identify conflicts and leverage.

- Set design targets.

Let's look at each of these steps in more detail.

Step 1: Determine Customer Requirements

This is the first part of the House of Quality that you build, because customer requirements must drive the organization's activities. If you try to do the reverse (by pushing product features instead of responding to market needs), you can find it hard to make sales.

You can also label this block "The Voice of the Customer." It contains a list of customer needs, using typical customer vocabulary and language. The information is often gathered through conversations with customers, and by listening to their needs and problems. You can then group the different needs and problems into subcategories such as functionality, performance, usability, and so on.

Figure 2 below shows an example of this first block, showing customers' input on their needs for a pen. In figure 8, you can see where this fits into the final House of Quality diagram.

Step 2: Compare Existing Products and Planning

With the second part of the House of Quality, you look at how competitors' products and your products compare according to these customer requirements. This helps you work out how important each requirement is, and it helps you think about how far you need to improve your existing product.

This table fits on the right hand side of the House of Quality diagram, and it looks like figure 3, below.

In this example, the first three columns show data from customer surveys, showing customers' scoring of the importance of different requirements, and their perceptions of your products compared with those of your competitors. Here, we're representing these scores running from 1 (lowest) to 5 (highest).

The fourth column shows the satisfaction scores we want from our new product, and the fifth column shows an improvement factor, defined as:

1 + [(Planned Satisfaction Rating – Actual Rating for Our Current Product) x 0.2]

0.2 is an "improvement variable". It's a value conventionally used when drawing up House of Quality diagrams, however, it's unclear what its purpose is, other than to bring the value range of the improvement factor to between 1 and 1.8. If appropriate, consider adjusting this figure, depending on how much weight you want to give to customers' perceptions of your products.

The sixth column, headed "Selling Point", indicates how far each customer requirement is actually a selling point for customers, which is an important factor in deciding how much attention to give it. The convention here is to use a scale of 1.0 to 1.5 for the extent to which a customer requirement is a selling point. Again, consider varying this factor if it doesn't give you the results you think it should.

The final column gives the customer requirement an overall relevance weighting, calculated as:

Overall Rating = Importance to Customer x Improvement Factor x Selling Point

Step 3: Define the Technical Requirements

Now it's time for the "Voice of the Company." The product described in Step 1, in terms of what customers want, is now described using in-house, technical terms. The design team produces this information, listing product characteristics that you can measure and that relate to meeting the customer expectations from Step 1.

You can show this information in a similar way to Step 1, grouping the separate items into categories. You can also add a row of arrows, pointing up or down, that indicate how the characteristic should be improved for higher customer satisfaction. For example, a down arrow for Pen Tube Diameter shows that a smaller diameter is preferable, and an up arrow for Refill Duration shows that a longer-lasting refill is better.

This is shown in Figure 4.

Step 4: Create the Interrelationship Matrix

This step links the Customer Requirements from Step 1 with the Technical Requirements from Step 3. Systematically analyze each customer requirement in terms of its relationship to each of the technical requirements, and determine the significance of the relationship. In each grid space, put a symbol to show whether the interrelationship is of high importance, medium importance, low importance, or no importance at all.

Then give each symbol a certain number of points depending on the level of importance it stands for. For example, you might award 8 points to high importance, 4 points to medium importance, 1 point to low importance, and 0 points to no importance. How you score each symbol, or ranking, depends on your particular project. (After you complete your House of Quality diagram, you may want to revisit this scoring system to see how different scorings affect the outcome.)

Figure 5 shows the matrix for our example, combined with two previous blocks from Step 1 and Step 3.

Step 5: Identify Conflicts and Leverage

After creating the interrelationship matrix, there may be conflicts in the technical requirements that correspond to different customer requirements.

For example, a requirement to make a product stronger may mean making it heavier – but perhaps customers also want it to be lighter. So, for each technical characteristic, use Step 5 to rate each combination of technical characteristics. In our example, higher manufacturing precision will allow the pen to have a narrower tube diameter, but having a longer refill duration conflicts with the wish to have a narrower tube diameter.

This is what creates the "roof" of the House of Quality, shown in Figure 6 together with the block from Step 3.

If improving one technical characteristic leads to weakening another one, then put a "minus" symbol in the corresponding cell. On the other hand, if it leads to improving the other characteristic, then put a "plus" there. Of course, you can choose other symbols or use different colors to show the strength of this improvement or the extent of this weakening.

It's up to you to determine how to resolve these conflicts. The value of the House of Quality diagram is to show where compromises may be necessary, or where opportunities exist to leverage a single improvement in several areas.

Step 6: Get the Final Result

This final step brings all of this analysis together to identify the following:

- Technical priorities.

- Competitive benchmarks.

The first row in this section identifies Technical Priorities . To calculate this, multiply the value associated with each symbol by the value of the Overall Weighting score in its row, and add these values up.

In our example, the technical priority for Pen Tube Diameter is calculated as (4 (yellow circle) x 7.8 (overall weighting for Long Lasting Refills))+ (8 (red square) x 3.1 (Overall Weighting for Fits in Any Pocket/Purse)) = 56.0.

The next rows identify the Competitive Benchmarks that must be met or beaten – these are usually characteristics of existing company and competitor products. In our example, Competitor A's best product has a Precision of 0.002 percent, a Refill Duration of 12 weeks, and a Pen Tube Diameter of 5 mm. Your new product has got to be better than this!

Finally, the Design Targets row shows you the characteristics of the product you want. You decide what these should be, based on your judgment and on the rest of your analysis. What's certain, though, is that you need to provide a product with technical requirements that your customers' value; that are better than existing products in important ways; and that can be manufactured cost-effectively.

You can see our example of this section in Figure 7.

Figure 8 shows all of the pieces of our example House of Quality diagram, brought together in the final diagram ( click to enlarge ).

House of Quality diagrams are the output of a structured process of analyzing what customers want from your products and services, and of thinking about how you can convert these wants into a practical design specification.

There are six main sections of the diagram, which are built up as you go through the House of Quality process: analysis of customer requirements; analysis of what's in the market and what's wanted by your customers; a study of technical requirements; a mapping of the interrelationships between customer needs and technical requirements; an analysis of compromises and leverage opportunities; and the setting of design targets.

To complete the different entries in the diagram, you must be methodical and check each step as you go. The final result, the design targets, involves using your judgment together with all of the information that you have gathered into the House of Quality diagram in the earlier steps.

Hauser, J. R. and Clausing, D. (1988). 'The House of Quality,' Harvard Business Review [online.] Available here .

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Zero defects.

Improving Product Quality and Eliminating Waste

Infographic

Garvin's Dimensions Infographic

Infographic Transcript

Add comment

Comments (0)

Be the first to comment!

Gain essential management and leadership skills

Busy schedule? No problem. Learn anytime, anywhere.

Subscribe to unlimited access to meticulously researched, evidence-based resources.

Join today and save on an annual membership!

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Latest Updates

Using Mediation To Resolve Conflict

Mind Tools Store

About Mind Tools Content

Discover something new today

Resolving workplace conflict through mediation.

Managing Disputes Informally

Personal SWOT Analysis

Making the Most of Your Talents and Opportunities

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

Organizational communication overview.

An Overview of Organizational Communication From a Strategic Perspective

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

How House of Quality Shapes Product Excellence

Updated: May 19, 2024 by Ken Feldman

HOQ is a summary diagram that is used as part of a structured approach to transform your voice of customer requirements into actual product specifications. This approach is called Quality Function Deployment (QFD) .

This article will discuss how to build the HOQ, present the benefits of the HOQ and some best practices to building and using the HOQ to develop your process or product to meet your customers’ needs and expectations.

Overview: What is House of Quality?

House of Quality, or HOQ, is a product planning matrix that is used to show how your customer requirements relate directly to the actions you can take to achieve those requirements.

HOQ diagrams resemble the shape of a house and should be created using direct customer input if applicable. HOQ is considered the primary tool in QFD and serves as the roadmap for describing the journey from initial idea to final product or service specifics.

Below is the template used for building your house.

Let’s briefly run through each room, the attic, and the basement to see how you can build this HOQ.

- Customer needs: For each critical customer segment, capture customer feedback and VOC input consisting of your customer’s needs and the priority or weight of each need.

- Customer critical requirements: The top row of the house contains the critical customer requirements (CCRs), also referred to as critical to customer (CTC) .

- Interrelationship matrix: Evaluate the relationship between your customer needs and CCRs. Determine the relative importance of each CCR.

- Customer rating of your competitors: How does your customer perceive the marketplace and your competition’s ability to meet each of their requirements?

- Correlation matrix: Compare CCRs to determine if they are in conflict with each other, leveraging each other, or have no effect on each other.

- Performance targets: Determine the necessary performance targets (specs) for each CCR.

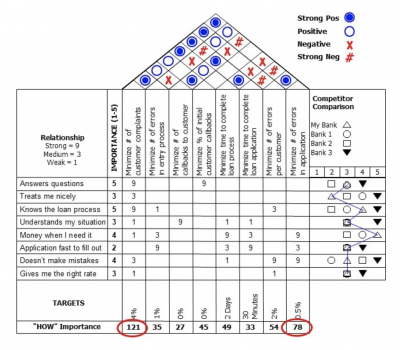

Below is an example for developing a new loan product for a bank. Note that the two design areas most important to the customer are reducing customer complaints (121) and minimizing errors in the application (78). It also seems that Bank 3 does a better job at meeting the requirements of the customer, and you should probably benchmark against them.

3 benefits of HOQ

Although it can be a bit of a pain to develop and build your HOQ, the benefits of having all of the elements in one easy-to-read diagram far outweigh the work and effort required to develop it.

1. Organize your efforts to satisfy your customers

The HOQ document is structured and the elements are linked. You can’t complete the house without building out each room.

2. Focus your development

Your focus is on customer needs and how to meet them using specific and quantifiable targets and metrics.

3. Understand your customer needs and document their requirements

The HOQ forces you to drive everything for the purpose of meeting your customer’s needs. By documenting and defining these needs, you will have a written and documented baseline to work towards developing the best design you can.

Why is HOQ important to understand?

While the diagram is simple in design, it’s important that you understand the correlation and interrelationships between the rooms.

Powerful tool

The power of HOQ is in the collaboration of team members, input of the customer, and the deep understanding of how to convert the customer what s to the design how s.

Correlation

There are two rooms that require you to understand and correlate relationships between them. You will need to understand what and how to do that and the relevancy of the importance ratings.

Delivering on the requirements

It’s one thing to design a process or product to meet your customer’s needs. It’s another to have the ability to produce that product or deliver that service. It will be important to coordinate with the rest of the organization to be sure that they understand how they can make your design tangible.

An industry example of HOQ

A large hospital chain decided to create a chain of freestanding clinics for general medical practices to alleviate some of the pressure on their emergency rooms. The CEO, who had some Six Sigma training, decided to use QFD to design the clinic and patient experience.

They followed the steps and built a HOQ. This required gathering patient feedback, determining processes, assessing the physical attributes of the clinic, correlating them, and setting targets. They also gathered competitive information about other clinics, both privately run and hospital-based.

In the end, they developed an optimal design that would satisfy their patient requirements and, at the same time, be feasible enough to actually build and manage the physical clinics.

3 best practices when thinking about HOQ

As I alluded to at the beginning of this article, the HOQ is often referred to as the HOP, or House of Pain. By following some best practices, you may be able to reduce that pain.

1. Direct and well-defined customer requirements

Don’t assume that you know what your customer wants or needs. Get that information directly from them, and be sure everyone is in agreement as to what they mean and how they will be measured.

2. Think quantitative, not just qualitative

The more things you can measure — and are supported by data — the less you leave to emotion and subjectivity.

3. Think outside the box, but be realistic

You may not be able to always design and deliver the world’s next best thing. Keep in mind the capabilities of your organization to actually deliver what you are designing.

Frequently Asked Questions (FAQ) about HOQ

What is house of quality .

The House of Quality (HOQ) is a product and process planning matrix diagram that’s used to show how customer requirements relate directly to how an organization can achieve those requirements.

What is the difference between HOQ and QFD?

HOQ is part of a larger process called Quality Function Deployment, or QFD. QFD is the process of deploying the design requirements from the HOQ to the functional areas of the organization for execution.

What are some of the advantages of using HOQ?

Here are a few advantages for using HOQ:

- Can reduce the time required for the design process

- Primary focus is on customer needs and requirements

- Can reduce design changes and revisions

- Can reduce time to market for your product or service

- Allows you to prioritize your design parameters

Let’s do a final tour of your House of Quality

The HOQ combines the various elements of a design process all in one easy-to-understand diagram. It starts with the customer and their requirements and ends with specific design solutions intended to meet those requirements.

Along the way, you identify targets and priorities and correlate design elements and requirements even to the point of benchmarking against your competitors.

About the Author

Ken Feldman

- Design & UX

How to make a House of Quality (a step-by-step guide)

Georgina Guthrie

October 06, 2023

In the late 1970s, a British inventor named James Dyson had a problem: his Hoover kept losing suction. His solution? Cyclonic irrigation, a process that meant a vacuum wouldn’t lose power as it picked up dirt.

When an inventor creates something to solve a personal problem, the customer-to-invention path is short and straight: the inventor is the customer, so they know exactly what’s needed. But what about entrepreneurs/business owners who want to innovate for someone other than themselves? How do they create something their customers truly want?

95% of new products fail , which implies the challenge is very real. Luckily, there are techniques to help you center your customer and create something that connects. House of Quality, which is an integral part of Quality Function Deployment, is one such tool. Here’s what you need to know.

What is QFD?

Quality Function Deployment (QFD) is the strategic framework within which the House of Quality tool sits.

Think of QFD as a broader product management methodology that brings customer needs to the forefront of every stage of product development.

It’s a systematic approach to design and development that prioritizes the voice of the customer (voC), translating their desires and expectations into relevant technical requirements.

Benefits of QFD

- Prioritize VoC : It keeps the needs and wants of the customer central in product development and service improvement processes.

- Boost collaboration : It creates an environment where different departments can collaborate efficiently and stay focused on common goals.

- Optimize resource allocation : It helps you spot focus areas and distribute resources according to priority/need.

- Develop competitive products : By aligning technical requirements with customer needs better than your competitors, you can create products and services that stand out.

- Facilitate communication: It gives a structured framework for communication between various parts of the org.

Key phases of the QFD process

Let’s take a look at the steps involved. The House of Quality spans steps 1-3; as you gather this information, you’ll add it to your diagram.

1. Identify customer requirements

This is the inception, where teams focus on collating customer needs, wants, and expectations. Here, interactions with customers, market research, and feedback analysis are paramount in pinpointing what the customer truly desires from the product or service.

2. Translate requirements into technical descriptors

This is where you make the leap from customer desires to cold, hard technicalities. Translate the gathered customer requirements into detailed technical descriptors. It’s about creating a coherent language that bridges customer expectations with the technical landscape, ensuring you address every nuance.

3. Competitor analysis

Once you’ve defined your technical descriptors, it’s time to assess the competitive landscape . Examining competitors’ offerings helps you spot gaps and opportunities for delivering a superior product or service. You’ll also want to come up with a competitive positioning strategy during this phase.

4. Develop product concepts

When you understand customer needs and the competition, it’s much easier for teams to develop coherent product concepts. This stage involves brainstorming and evaluating potential solutions, ensuring each concept is rooted in your customer needs.

5. Determine product characteristics

During this stage, teams define the product’s characteristics, features, and functionalities, ensuring every element reflects both customer needs and the wider business goals.

6. Create detailed design

This is where the rubber meets the road. Teams develop detailed designs, encompassing every aspect of the product, from features to functionalities. It’s about ensuring every element aligns with the defined product characteristics and meets customer expectations.

7. Develop production process

Finally, the focus shifts to the operational aspect. Here, teams fine-tune production processes, ensuring efficiency, precision, and adherence to quality standards.

What is a House of Quality?

The House of Quality is like the architect’s blueprint in the realm of product development. It’s a part of Quality Function Deployment (QFD), a methodology aimed at ensuring the customer’s voice is the loudest in the room when designing or improving a product or service.

In simpler terms, it’s a matrix, much like a detailed table or chart, where customer needs meet technical requirements, providing a visual representation of the relationship between what the customer wants and how the organization can meet those wants.

A House of Quality diagram helps you:

- Visualize the all-important customer-technical relationship : It offers a detailed matrix for visualizing and understanding the relationship between customer requirements and technical specifications.

- Translate needs into actions : It acts as a translator, converting customer desires into tangible technical requirements. These, in turn, translate into tasks.

- Identify areas for improvement : It helps you pinpoint the specific areas that need a little fine-tuning.

- Encourage interdisciplinary dialogue : It serves as a unified platform to facilitate conversations between varying technical landscapes and customer-centric viewpoints.

- Ensure quality and value : By aligning customer desires with organizational capabilities, it helps you deliver products and services of the highest quality.

How to make a House of Quality diagram

Below is a basic House of Quality diagram. To the left, you’ll list your customer requirements. In the columns to the right, you’ll typically find a series of ratings to help you prioritize product features , including importance ratings, technical requirements, and achievability.

A house of quality example. Image source: researchgate.net

To bring this process to life, let’s imagine we’re developing a new line of ergonomic office chairs.

Objective : Start by identifying what potential customers are looking for in an ergonomic office chair.

Process:

a. To gather crucial data, carry out market research, user interviews, and run surveys using both qualitative and quantitative methods .

b. After collecting ample information, distill it to extract and list prominent customer requirements, focusing on aspects that users find most valuable.

Example : For our ergonomic office chair, we discovered that customers prioritize lumbar support, adjustable height, swivel capability, and cushion comfort.

Step 2: List technical descriptors

Objective : Translating customer requirements into technical terms will help guide design and production teams. You’ll list these along the top of the matrix. For instance, lumbar support could translate to the curvature degree of the backrest, and adjustable height could relate to the range of height adjustments available. This step involves diving deep into the specifics, ensuring every customer need has a corresponding, actionable, and measurable technical counterpart.

a. Identify corresponding technical specifications for each customer requirement.

b. Position these technical descriptors across the top of your matrix.

Example : For lumbar support, a critical specification could be the curvature degree of the backrest, and for adjustable height, we’ll look at the range of height adjustments available.

Step 3: Analyze competitor offerings

Objective : Before jumping into relationships and correlations, analyze the competitive landscape. Evaluate how competing office chairs meet the identified customer requirements. This comparative analysis gives you insight into existing gaps in the market, as well as opportunities for innovation and differentiation. Leave no stone unturned: product specifications, user reviews, and market positioning of competitor products are all good places to look.

a. Select a range of competitors’ products and list them for comparison.

b. Assess each product against the identified customer requirements, and document this information in the corresponding section of the matrix.

Example : We compare various ergonomic chairs from different brands, focusing on how well they align with the outlined customer requirements.

Step 4: Establish relationships

Objective : It’s time to connect the dots between what customers want and the technical attributes that meet those needs. In the main body of the matrix, connect the customer requirements with their corresponding technical descriptors. Use symbols to denote the strength of each relationship, marking strong, medium, or weak correlations. This step necessitates a nuanced understanding of how each technical specification impacts the fulfillment of the customer’s desires and expectations. It’s crucial to be precise to ensure the final product genuinely aligns with user needs.

a. Use the body of your matrix to create symbols denoting the strength of the relationships (e.g., strong, medium, weak).

b. A consistent legend with circles, triangles, or squares can help depict the strength of each relationship.

Example : We carefully examine how the degree of backrest curvature impacts lumbar support.

Step 5: Determine the weight

Objective : Based on the research and feedback collected, assign weights to each customer requirement based on its importance to the user. For example, if lumbar support is a high priority for the target audience, it would receive a higher weight relative to other requirements. This weighting process is crucial as it guides resource allocation and focus throughout the development stages, ensuring alignment with user priorities.

a. Utilize your market research data to ascertain the importance of each requirement and assign appropriate weights.

b. Input these weights in the designated area of your matrix.

Example : Lumbar support is highly valued by our target audience. This means it’s assigned a higher weight compared with other requirements.

Step 6: Set target values

Objective : For every technical descriptor, establish clear, specific target values. If lumbar support is translated into curvature degree, decide the exact degree that the chair should offer. Setting these target values provides clear goals for the design and production teams and serves as benchmarks against which the product’s success can be measured.

a. Determine the exact specifications your ergonomic office chair should meet.

b. Document these precise target values in the corresponding part of your matrix.

Example : We specify the exact curvature degree for optimal lumbar support and the allowable range for height adjustments.

Step 7: Assess the correlation

Objective : Lastly, assess how each technical descriptor correlates with the others. Understand if enhancing one aspect may affect another adversely, such as increasing cushion comfort potentially compromising on the chair’s breathability. These correlations, whether synergistic or conflicting, need careful consideration to balance different elements effectively and deliver a harmonious, well-rounded final product.

a. Explore the interdependencies among technical descriptors, identifying any synergies or conflicts.

b. Use symbols (e.g., ‘+’ for positive correlation, ‘−’ for negative correlation) in the roof of your matrix to represent these relationships.

Example : A critical assessment reveals whether enhancing cushion comfort might compromise the breathability of the chair.

Once you’ve completed and reviewed your matrix, it should offer a cohesive overview, linking customer desires to actionable technical specifications. This diagram will act as a beacon, helping design and production teams to align their endeavors with customer expectations and market needs for the ergonomic office chair.

Don’t hesitate to revisit and adjust your matrix as needed to keep insights in the forefront as you navigate the product development phases.

House of Quality diagrams: best practice

- Define customer requirements clearly

Focus on clarity and conciseness when articulating customer requirements. A well-researched and precise foundation is crucial for the whole process to run smoothly.

- Maintain open communication between departments

Facilitate collaboration to keep all departments aligned. This cohesive approach helps in addressing concerns and refining ideas effectively.

- Be prepared to revisit and revise

Understand that a House of Quality is dynamic and may need adjustments. Stay adaptable and refine your approach as customer needs evolve or new information comes in.

- Use diagramming tools

Employ tools like Cacoo to create visually intuitive diagrams. Diagramming software helps in making the process faster (drag-and-drop interfaces are a godsend), ensuring ease, speed, and accuracy. Create and share with a few clicks, add comments, and stay on top of version control.

Who should use QFD?

Quality Function Deployment (QFD) isn’t just for engineers or product designers; it’s a versatile approach that benefits a broad range of professionals and organizations aiming to align their offerings with customer needs.

If you’re in marketing, QFD helps you understand what the customer really wants, which in turn helps shape your messaging and promo strategies. For those in product development or manufacturing, it helps translate those ever-elusive customer desires into tangible, actionable design specs, ensuring the final product aligns with audience expectations.

For leaders and decision-makers, QFD offers a customer-centric method for driving innovation. It also helps foster a culture focused on continuous improvement and customer satisfaction. It brings clarity and direction, anchoring product development in real-world needs, thus reducing the risks associated with new product development.

QFD is an essential business survival tool

In a marketplace brimming with choices, understanding and responding to customer needs isn’t just good practice — it’s a survival tactic.

QFD, with its structured approach to integrating customer requirements into every stage of product development, offers a competitive edge. It helps you spot opportunities for innovation, reducing development costs by identifying and resolving issues early, and accelerating time to market.

So, whether you’re crafting marketing strategies, refining products, or making high-stakes decisions, integrating QFD can be the catalyst for delivering products that not only meet but exceed customer expectations, strengthening brand loyalty and ensuring your business is in the 5% that create winning products, and not the 95% that don’t.